All Categories

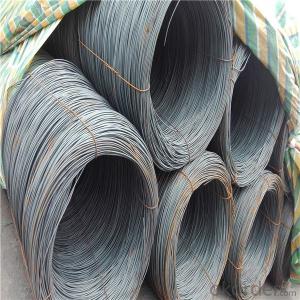

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

How do steel wire rods perform in applications subjected to harsh weather conditions and corrosion?

Steel wire rods perform well in applications subjected to harsh weather conditions and corrosion due to their inherent strength, durability, and corrosion resistance. The steel used in wire rods is typically treated with coatings or alloys that enhance its ability to withstand harsh environments. These protective measures prevent rusting and corrosion, ensuring the longevity and reliability of steel wire rods in such challenging conditions.

What are the environmental implications of steel wire rod production and recycling?

The environmental implications of steel wire rod production and recycling are significant but can be mitigated through sustainable practices. In terms of production, the extraction and processing of raw materials, such as iron ore and coal, contribute to deforestation, habitat destruction, and air and water pollution. Additionally, the energy-intensive nature of steel production leads to greenhouse gas emissions and contributes to climate change.

However, recycling steel wire rods offers several environmental benefits. Firstly, it reduces the need for raw material extraction, conserving natural resources and minimizing the associated environmental impacts. Recycling also requires less energy compared to primary production, resulting in lower carbon emissions. Moreover, it helps decrease landfill waste and associated pollution.

To further mitigate the environmental implications, steel wire rod manufacturers can adopt cleaner production technologies, invest in renewable energy sources, and implement efficient waste management practices. Promoting a circular economy through increased recycling rates and designing products for easier disassembly and recycling can also minimize environmental impacts.

How are steel wire rods used in the production of nails and screws?

Steel wire rods are used as the primary raw material in the production of nails and screws. These rods are shaped into the desired diameters and lengths through a series of manufacturing processes, such as drawing and cutting. The resulting wire is then fed into specialized machines that form the wire into nail or screw shapes. The steel wire rods provide the necessary strength and durability to the final products, ensuring that nails and screws can effectively hold materials together.

Wholesale Steel Wire Rod from supplier in Algeria

We are confident that our Steel Wire Rod products and services will meet your expectations and help you achieve your project goals. Our team is ready to assist you with any inquiries and provide you with the necessary information to make informed decisions. Trust us as your reliable supplier of Steel Wire Rod in Algeria and let us contribute to the success of your projects. Contact us today to get started.