All Categories

- - Steel Wire Rod

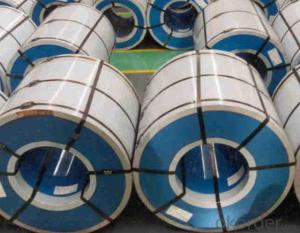

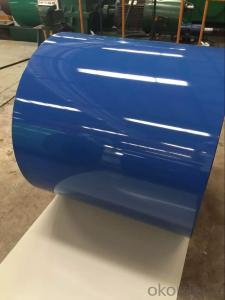

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

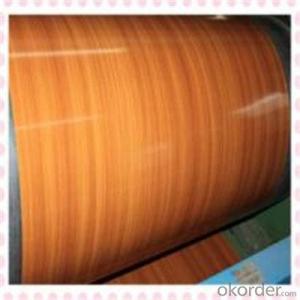

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

How is coil edge quality maintained during the manufacturing of electrical components?

Coil edge quality is maintained during the manufacturing of electrical components through several measures. Firstly, precision cutting techniques are employed to ensure clean and accurate edges of the coil. This helps in eliminating any irregularities or deformations that may affect the performance of the component.

Furthermore, quality control checks are conducted at various stages of the manufacturing process to identify and rectify any potential issues related to coil edge quality. These checks may include visual inspections, dimensional measurements, and tests for electrical conductivity.

Additionally, specialized machinery and tools are utilized to handle and process the coils with care, minimizing the risk of damage or distortion to the edges. Proper handling techniques, such as controlled tension and alignment, are also employed to maintain the integrity of the coil edges.

Overall, a combination of precise cutting, stringent quality control measures, and proper handling techniques play a crucial role in maintaining coil edge quality during the manufacturing of electrical components.

What is the significance of coil packaging and banding for safe transportation in the aerospace sector?

Coil packaging and banding play a crucial role in ensuring safe transportation in the aerospace sector. Aerospace components, such as coils, are often delicate and require extra protection during transit to prevent damage or distortion. By securely packaging and banding the coils, it reduces the risk of shifting, vibration, or impact during transportation. This helps maintain the integrity of the coils, ensuring they arrive at their destination in optimal condition, ready for use in critical aerospace applications.

How are steel coils tested for surface waviness?

Steel coils are tested for surface waviness through a method called optical inspection. This involves using specialized cameras and lighting systems to capture high-resolution images of the coil surfaces. These images are then analyzed by software algorithms that detect and measure any waviness or irregularities in the surface.

Wholesale Steel Coils from supplier in Slovakia

With our strong network and partnerships, we are able to source high-quality Steel Coils from reliable manufacturers and ensure competitive prices for our customers. Our team of experienced professionals is dedicated to understanding your specific requirements and providing tailored solutions to meet your needs.

In addition to our sales and procurement services, we also offer comprehensive technical support to assist you throughout your project. Whether you need assistance with product selection, technical specifications, or installation guidance, our knowledgeable team is here to help.

At our company, we prioritize customer satisfaction and strive to build long-term relationships based on trust and reliability. We understand the importance of timely deliveries and efficient logistics, and we work closely with our partners to ensure smooth and hassle-free transactions.

Furthermore, our affiliation with CNBM, a leading global company in the steel industry, gives us access to a vast pool of resources and expertise. This enables us to stay updated with the latest market trends and technologies, allowing us to provide innovative solutions to our customers.

If you are looking for a reliable and experienced supplier of Steel Coils in Slovakia, we are here to assist you. Contact us today to discuss your requirements and let us provide you with the best procurement solutions for your upcoming projects.

In addition to our sales and procurement services, we also offer comprehensive technical support to assist you throughout your project. Whether you need assistance with product selection, technical specifications, or installation guidance, our knowledgeable team is here to help.

At our company, we prioritize customer satisfaction and strive to build long-term relationships based on trust and reliability. We understand the importance of timely deliveries and efficient logistics, and we work closely with our partners to ensure smooth and hassle-free transactions.

Furthermore, our affiliation with CNBM, a leading global company in the steel industry, gives us access to a vast pool of resources and expertise. This enables us to stay updated with the latest market trends and technologies, allowing us to provide innovative solutions to our customers.

If you are looking for a reliable and experienced supplier of Steel Coils in Slovakia, we are here to assist you. Contact us today to discuss your requirements and let us provide you with the best procurement solutions for your upcoming projects.