Fireclay Brick for Hot Blast Stove

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

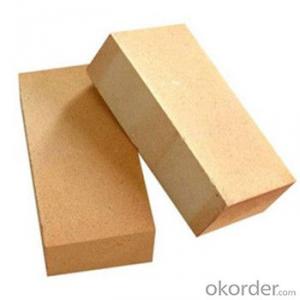

Quick Details for Fireclay Bricks for Hot Blast Stove

| Place of Origin: | China (Mainland) | Shape: | Brick | Material: | superfine burned flint clay/high quality combined clay/ additives |

| Brand Name: |

Packaging & Delivery

| Packaging Details: | manner of packing:Fumigation wooden pallets+paper angle bead+PET strap+stretch film. Wooden pallet size:930*930mm load weight of each pallet:1.5-2.0 tons |

| Delivery Detail: | within 30 days after signing the contract |

Specifications

1.Lower creep

2.To maintain the service life of the kiln

![]()

Such product selected superfine burned flint clay and high quality combined clay as main raw materials, and also selected materials which not easy to shrink and react with minerals at high temperature as additive . After high pressure shaping and high temperature firing , we can get this product.So the product has high strength,high density and low creep rate,and it can better applied to the hot blast furnace,glass furnace and chemical furnaces,etc.

![]()

| Product Item | XX | X | N43 | N42 | N41 | DRN-125 | DRN-120 | DRN-115 | DRN-110 |

| Fe2O3 % | ≥42 | ≥39 | ≥40 | ≥40 | ≥42 | ≥45 | ≥42 | ≥40 | ≥36 |

| Refractoriness °C | ≥1750 | ≥1730 | ≥1730 | ≥1730 | ≥1750 | ||||

| Apparent Porosity % | ≤20 | ≤22 | ≤24 | ≤24 | ≤24 | ≤22(24) | ≤22(24) | ≤22(24) | ≤22(24) |

| Bulk density g/cm3 | ≥2.15 | ≥2.10 | ≥2.10 | ≥2.15 | ≥2.25 | ≥2.25 | ≥2.15 | ≥2.10 | ≥2.10 |

| Cold crushing strength Mpa | ≥35 | ≥35 | ≥30 | ≥30 | ≥30 | ≥40 | ≥35 | ≥30 | ≥25 |

| Refractoriness under load KD,°C | ≥1450 | ≥1400 | ≥1400 | ≥1450 | ≥1450 | ||||

| Permanent Linear Change % | 1400°C×4h ±0.2 | 1400°C×4h ±0.2 | 1300°C×2h ±0.2 | 1350°C×2h ±0.2 | 1400°C×2h ±0.2 | 1400°C×2h -0.4~0.1 | 1350°C×2h -0.4~0.1 | 1300°C×2h -0.5~0.1 | 1300°C×2h -0.5~0.1 |

| creep rate(0.2Mpa*50h)% | 1250°C *(20-50) ≤0.2 | 1200°C *(20-50) ≤0.2 | 1150°C ≤0.8 | 1200°C ≤0.8 | 1250°C ≤0.8 | 1250°C ≤0.8 | 1200°C ≤0.8 | 1150°C ≤0.8 | 1100°C ≤0.8 |

| Application | Regenerative chamber walls and the grid of hot air stove, and the combustion chamber and air chamber of mixed contact tube and various burner brick | ||||||||

![]()

It is widely used in hot blast furnace,glass furnace and chemical furnaces,etc.

![]()

1.Strong professional:

A:The manager of our company has 50 years working experience in refractory product, technology and trading. He has professional function on a various refractory’ s production materials, process control, quality supervision and package delivery.

B: .Company staff are very familiar with refractory and professional knowledge is very good .

C:Company staff are all college culture level.

2. .Annual supply:

Our company has a dozen cooperative production factories which are better in productive technology and quality management. All the factories has passed ISO9001 quality management system certification. And the annual supply of dense shaped and unshaped refractory product is 100,000-200,000 tons.

3. Annual exports:

Now we have exported more than ten countries , such as Asia ,Europe and South America.The average annual export amount is 10 million Yuan , about $1.6 million.

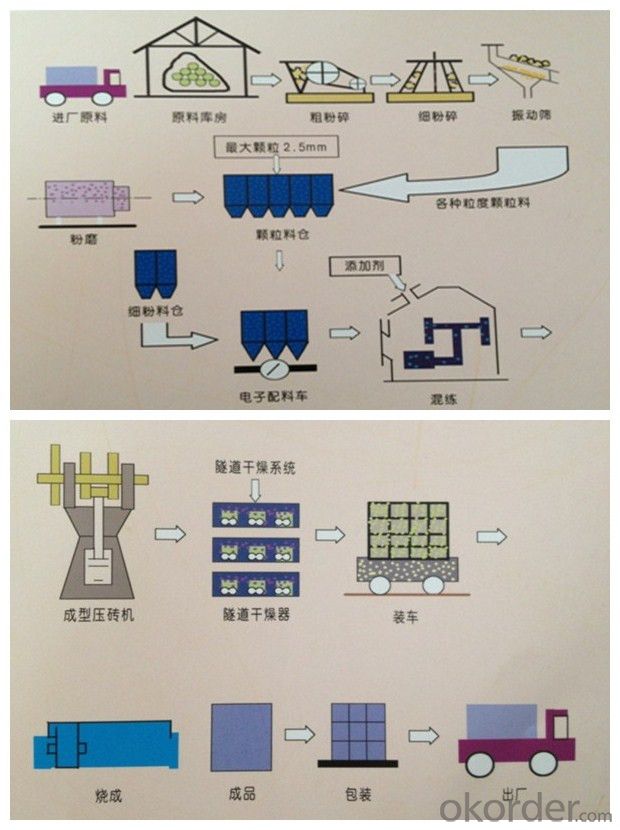

4. Production equipment:

Production and testing equipments are new, complete and automated or semi- automated. Such modern facilities and equipments have provided the fine technical guarantee for the production and testing.

5. Process flowdiagram:

6. Order processing:

After the contract is signed, the relevant responsible person tracked production progress, product quality and product packing aperiodically. During the term of contract sent on time with quantity and quality guaranteed.

Why choose us?

1.Competitive price and stable quality to be offered Our refractory materials has export to South America,Australia,Malaysia,UK,etc for many country.

2.Our company provide customer with satisfactory products and services

3.Maybe our price is not the lowest, but our Brick quality is the most trusted

4.we are the real maker and supplier in China, not the middleman.

If you have any questions, we will try our best to satisfy your requirements

Welcome to visit our factory.

- Q: How to built refractory bricks as fitting between square and circle ducts

- Use rectangle at the bottom and knife type for the top. trapezoid for junction.

- Q: Scheme of cement kiln replacing 40 meter refractory brick kiln

- If only replace refractory bricks, it just needs three days under the condition of 200 degrees. It will be simpler if there is only free water in the refractory brick (no pouring material).

- Q: is it correct that the higher the refractoriness is, the better refractory bricks are?

- Does not necessarily, it has a great relationship with the compression and bending and corrosion resistance.

- Q: Is there any special requirements for the building blocks of the smoke and gas wells, how about the refractory bricks?

- There are no special requirements. Not necessarily need refractory bricks, red bricks are ok. The building size of the flue is according to the smoke exhaust rate.

- Q: How to do refractory bricks

- There are many varieties of refractory bricks, and the pratice of it is similar to ordinary brick practice, but the requirements of equipment and technology will be much higher

- Q: What are the type, location and the physical and chemical effects of the refractory brick used in the cement rotary kiln?

- And T209

- Q: Can you direct the clay brick walls embryo

- Times are different, where there is no modern calcination process. With glutinous rice water in the soil, but glue well, but there is no comparable with cement and other building materials. Not long, can not withstand weathering.

- Q: What mud is the refractory brick made of?

- The main material of the ordinary refractory brick is clay, the main component is aluminium oxide.

- Q: Can refractory bricks be used to build a house?

- Refractory brick can be used to build houses, but you can not use ordinary cement to build, the cost is 3 times than that of ordinary brick.

Send your message to us

Fireclay Brick for Hot Blast Stove

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords