Stove Top Aluminum Foil

Stove Top Aluminum Foil Related Searches

Aluminum Foil For Stove Top Stove Aluminum Foil Cover Gas Stove Aluminum Foil Aluminum Foil On Stove Aluminum Foil For Stove Aluminum Foil To Cover Stove Electric Stove Aluminum Foil Stove Popcorn Aluminum Foil Aluminum Foil Stove Liner Cooking Aluminum Foil Aluminum Foil Stove Burner Oven Aluminum Foil Kitchen Aluminum Foil Steam Aluminum Foil Microwave Oven Aluminum Foil Baking Pan Aluminum Foil Steak Aluminum Foil Grill Pan Aluminum Foil Aluminum Foil For Oven Aluminum Foil In Oven Bottom Bake Aluminum Foil Boil Aluminum Foil Boiling Aluminum Foil Baking Aluminum Foil Roof Aluminum Foil Grill Steak Aluminum Foil Aluminum Foil Pan Grilling Aluminum Foil High Quality Aluminum Foil Sticky Aluminum FoilStove Top Aluminum Foil Supplier & Manufacturer from China

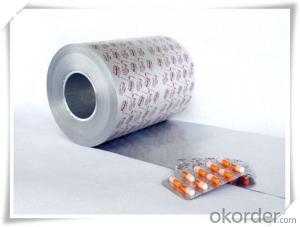

Stove Top Aluminum Foil is a versatile product that is widely used in various cooking applications. It is designed to withstand high temperatures, making it an ideal choice for covering stovetops, grills, and other cooking surfaces. This product is made from high-quality aluminum, ensuring durability and effectiveness in protecting surfaces from spills, splatters, and heat damage. The aluminum foil is also easy to cut and shape, allowing users to customize it according to their specific needs.Stove Top Aluminum Foil is an essential item in both residential and commercial kitchens. It is commonly used to cover stovetops during cooking to prevent messes and make cleanup easier. Additionally, it can be used to wrap food items for baking, grilling, or roasting, preserving the food's natural flavors and moisture. The product is also suitable for use in food storage, as it helps to keep food fresh and protected from external contaminants.

Okorder.com is a reputable wholesale supplier of Stove Top Aluminum Foil, offering a vast inventory of this product to cater to the needs of various customers. They pride themselves on providing high-quality products at competitive prices, ensuring that their customers receive the best value for their money. With their extensive selection and commitment to customer satisfaction, Okorder.com is the go-to source for those looking to purchase Stove Top Aluminum Foil in bulk.

Hot Products