Fireclay Brick for Hot-Blast Stove

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 kg

- Supply Capability:

- 2000000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

High alumina fireclay Brick

High alumina fireclay Brick for Heating Furnace is a kind of insulation material adopting organic matter as ignition loss substance in order to increase the porosity of refractory, which has such advantages as high porosity, small volume density, good insulation effect, high mechanical intensity, small thermal conductivity and long service life. For various industrial kilns & furnaces, it is a kind of essential refractory for energy saving and temperature preservation.

This series of High Alumina fireclay Brick for Heating Furnace are made of selected high alumina bauxite, kaolin caly, hollow microsphere as the mian material.By shaping at high pressure and sintering at high temperature.

Fireclay brick is shaped refractory product.It is made from flint clay clinker and binder , Through high heat sintering. The Al2O3 content range from 28% to 48%.The refractoriness range from 1580°C to 1750°C(SK-30.SK-32.SK-34.SK-35).

Product Applications:

High alumina fireclay Brick are ideal for use in the below applications

Furnaces of metallurgy industry, heat treatment furnace

Furnaces of chemical industry and construction industry.

Furnace of incineration of garbage, recirculating fluidized bed furnace

Standard sizing: 230 x 114 x 65 mm others up to the client

Product Advantages:

CNBM has success in its Fireclay brick due to their cost-effectiveness and excellent insulating properties. CNBM also has experience in ceramic fiber blankets application and would like to assist you in product selection, system design, and installation techniques.

Main Product Features:

High refractoriness,High-temperature endurable .

Good corrosion resistance.

Good spalling resistance and wear resistance.

Good thermal shock resistance.

High mechanical strength.

High-temperature creep rate is low.

Good volume stability at high temperature.

Product Specifications:

ITEM | UNF42 | UNF46 | ZGN42 | RN40 | TDL45-12 |

Refractoriness, ℃ | 1730 | 1750 | 1750 | 1730 | 1760 |

Bulk Density, g/cm3 | 2.15 | 2.25 | 2.3 | 2.15 | 2.37 |

Apparent Porosity, % | 22 | 20 | 15 | 24 | 12 |

C.C.S, Mpa | 30 | 35 | 58 | 28 | 68 |

Refractories Under Load (0.2Mpa),℃ | 1400 | 1420 | 1450 | 1430 | 1500 |

Reheating Linear Change, % | 1400℃x2h 0.1~-0.4 | 1430℃x2h 0~-0.1 | 1450℃x2h 0~-0.2 | 1350℃x2h 0~-0.3 | 1450℃x2h -0.1~+0.05 |

Al2O3 Content , % | 42 | 46 | 42 | 40 | 45 |

Size :

Common sizes

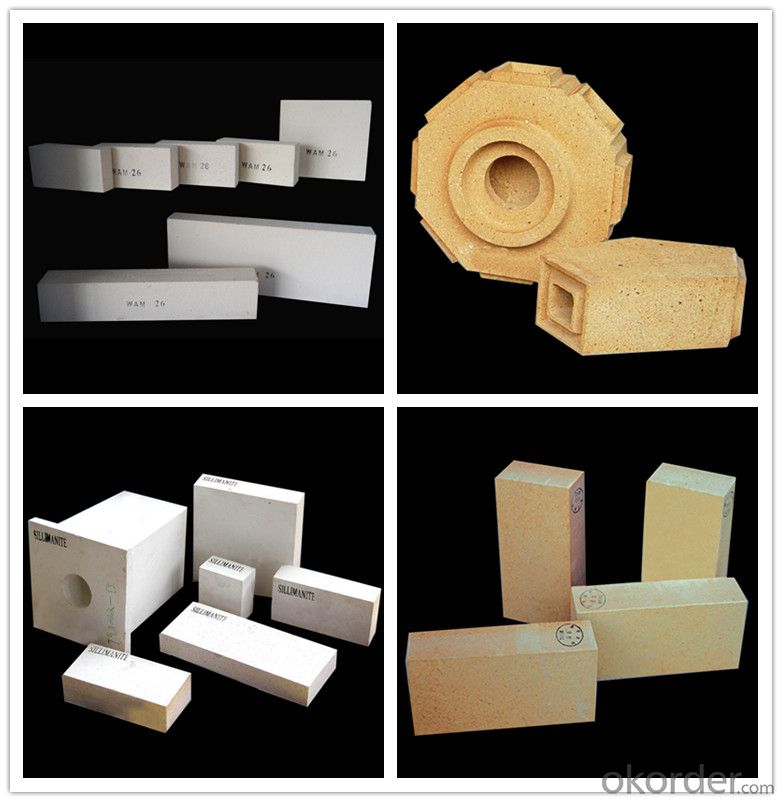

Straight type | Arch type | Wedge type |

L×W×H (mm) 230×114×65 230×114×75 230×114×32 220×110×60 220×110×50 220×110×40 220×110×30 | L×W×H/h (mm) 230×114×65/55 230×114×65/45 230×114×65/59 220×110×65/50 220×110×75/65 220×110×60/40 | L×W×H/h (mm) 230×114×65/55 230×114×65/45 220×110×75/65 220×110×60/40 |

Other sizes according to customer requirements | ||

FAQ:

Q1: How about your factory’s annual production capacity?

A1:CMAX annual production is about 310,000Tons.

Q2: How many production lines of your factory?

A2:CMAX has 26 production lines, including eight silicon bricks lines, and each one of mullite brick, high alumina brick, insulating brick and monolithics line.

Q3:How large the scale of your factory?

A3: CMAX covers almost 200,000 Square meters, including plant area of 180,000 square meters.

Q4: What’s your factory’s product scope?

A4:CMAX main products are: refractory for hot blast stove, refractory for coke oven, refractory for glass kiln, refractory for carbon calcining furnace, refractory for acid pickling line, refractory for cement kiln, refractory for blast furnace, refractory for nonferrous metal furnace, and basic refractory raw materials.

Product Picture

Produce Processing

Crushing

In this stage massive raw materials which have been stored, are ground and classified into proper sizes, making them easier to shape.

Mixing

The prescribed size of ground raw material is weighed and mixed into a designated amount of water and forming agent.

Shaping

The mixture is then poured into a mold to form shapes, and the pressure is high.

Drying

In this stage water is removed from the shaped bricks. This helps preventing the bricks from deforming or cracking which may result due to the rapid evaporation

Firing

This is the most crucial process in refractory manufacturing. The modeled bricks are fired at high temperature to complete their thermochemical reaction so that they do not deform.

Inspection

The bricks' physical and chemical properties are inspected very carefully by rigid quality management procedures.

Packing shipment

We guarantee efficient delivery every time.

Packing

We also supply (Click on following picture if interested):

- Q: does furnace use refractory cement to make refractory bricks?

- use refractory clay, refractory clay is made of refractory clinker clay mixing with cornstarch in a certain proportion, generally refractory cement refers to alumina?cement, which is generally used in castable refractory, producing binder.

- Q: How much is the silica powder in refractory bricks.

- It's not easy to construct, also need to consider the technical and economic indexes, DH3, 1 kg silica powder replaces 1 ~ 3 kg cement, which is the reason why silicon powder was not used and spreaded in concrete in past, choose some silica power fume. In general, with the smoke escaping by special capture device for collecting and processing To determine the mixing method of silica powder, when mixing silica powder, you should find out the optimal dosage in order to obtain the best results, as the study, the content is 5% ~ 30%, H, the mixing of super high strength concrete, use same amount of silicon powder to replace equal cement to main same fluidity, Microsilica or Silica Fume, it is mainly according to the design requirements, and does not reduce the amount of cement, sand and stone to adjust the optimal dosage of water reducer, when deciding the best mixing amount of silica fume, the concrete is too sticky, most use naphthalene water reducing agent.

- Q: What types of refractory bricks are divided into?

- middle rank。 A refractory is stronger than B refractory, low rank, the other is refractory, the senior is AB. Shale is hollow, it is not refractory, refractory, advanced, refractory B, there are nonfireproof materials in intermediate and low rank. Three types of refractory A

- Q: why the color of refractory brick is white after high temperature firing when the meteorite is black after the burning?

- There are different reasons. Meteorolites can mainly be divided into three types, iron meteorites (iron nickel alloy): Stone meteorites (the main component is silicate), and stony iron meteorites(the mixture of iron and silicate)

- Q: Do cement kiln refractory bricks have quality guarantee period? can them still be used for a long time's pile?

- They of course can be used. The plant will produce some bricks for standby application in advance, so they put for a period of time is completely no problem

- Q: What is the advantage of the ceramic fiber material compared with the refractory brick?

- Ceramic fiber material is heavier than refractory bricks, property of machinery operation, low heat capacity, and has high anti-stretchability and good thermal shock resistance, low thermal conductivity make its thermal insulation effect is ten times than refractory brick, it won't has crack in sudden coolness and heat, and the construction is much easier than that of refractory brick, not delaying the production.

- Q: What materials mix mortar to build walls (with bricks)? The more burned the harder

- Refractory mortar

- Q: The shape and size of general used refractory brick

- According to the national standard, the outline dimension of mechanism red brick is: length is 240mm, width is 115mm and thickness is 53mm. That is: 240mm * 115mm * 53mm. The shape and size of the ordinary refractory bricks are: Length is 230mm, width is 114mm and thickness is 65mm, that is: 230mm * 114mm * 65mm. The shape and size of special refractory bricks are: 345mm*328mm*97mm.

- Q: Where are clay bricks or cement bricks?

- Are clay bricks made of ordinary buildings or clay bricks on refractory materials?. Ordinary clay brick building is a burning clay made of red brick, (that is, the original old house with a little red brick) due to its extensive use of native resources and have great pollution in firing, now in some city has banned the use of the.

Send your message to us

Fireclay Brick for Hot-Blast Stove

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 kg

- Supply Capability:

- 2000000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords