Fireclay Brick for Refractory Heat Insulation

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 100 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description:

High alumina fireclay Brick for Heating Furnace is a kind of insulation material adopting organic matter as ignition loss substance in order to increase the porosity of refractory, which has such advantages as high porosity, small volume density, good insulation effect, high mechanical intensity, small thermal conductivity and long service life. For various industrial kilns & furnaces, it is a kind of essential refractory for energy saving and temperature preservation.

This series of High Alumina fireclay Brick for Heating Furnace are made of selected high alumina bauxite, kaolin clay, hollow microsphere as the mian material.By shaping at high pressure and sintering at high temperature

Product Applications:

1. Furances of glass,coke oven,electric and so on

2.Furnaces of metallurgy industry, heat treatment furnace

3. Furnaces of chemical industry and construction industry.

4. Furnace of incineration of garbage, recirculating fluidized bed furnace

Main Product Features:

1. Low porosity,High bulk density.

2. High Cold Crushing strength.

3. High refractoriness under load.

4. High mechanical strength.

5. Good resistance to erosion.

Product Specifications:

1.With 55% Al2O3 min;

2. Refractoriness: 1750C min;

3.For steelmaking furnaces;

4.ISO 9001 Certificate;

5.Custom shape;

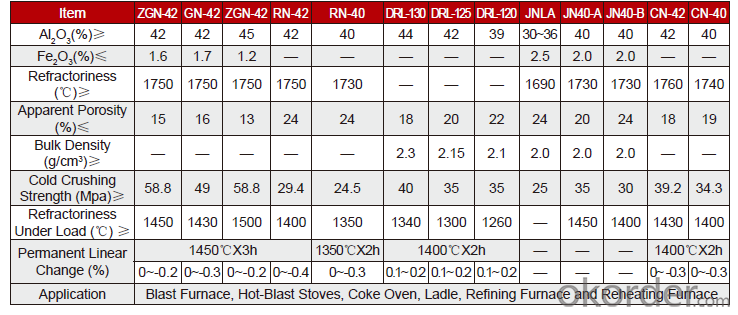

Technical data:

FAQs:

Q1 What’s the transport method?

A1 FCL delivery goods with wooden pallet or wooden case by sea; If LCL delivery, must with wooden case; Sometimes need open top, flat rack or bulk cargo.

Q2 What’s the required payment term?

A2 Generally 30% TT as the prepayment, 70% TT before delivery. If need, 100% Irrevocable Letter of Credit or negotiation.

Q3 Which country are our products exported to?

A3 Apart from entire Chinese market, the US, Russia, Japan, Korea, Australia and some Southeast Asian Nations.

- Q: how to distinguish the quality of high alumina refractory brick when you buy it ?

- see the gap between the bricks and between kiln roof and kiln wall, etc.. 6, the pressure and the volume density of Pei brick and brick Pei size, appropreate matching of high alumina powder and high aluminous aggregate and other materials, the drying and time, and the mud trapped material humidity 1. 7, to reach the requirements of production. 4, the order of loading Pei brick into kiln . should prevent the lack of a scene , the requirement , mixing time, different procedure and the order of the adding of raw materials of high alumina brick. 3, drawing plan and lack of edge of high alumina brick . 5

- Q: What are the weak points of clay bricks?

- Clay bricks are clay products with Al2O3 content of 30%~40% aluminum silicate material. Clay brick is made of 50% soft clay and 50% hard clay clinker, according to the requirements of a certain particle size. After molding and drying, the clay brick is burnt at high temperature 1300~1400 degrees celsius. The mineral composition of clay brick is mainly kaolinite (Al2O3, 2SiO2, 2H2O) and 6%~7% impurities (potassium, sodium, calcium, titanium, iron oxides). The sintering process of clay brick is mainly the process of the continuous dehydration of kaolinite and the formation of crystallization of mullite (3Al2O3. 2SiO2).

- Q: is it good to use firebricks to preserve the heat of rto furnace? Is there any other good ideas?

- 1. what variety and grade of refractory materials should be chosen to build all parts of the industrial furnace?; 2. is the origin of these materials be assured? mesothern resistance furnace, lightweight refractory brick, refractory fiber, bead brick of 1000 degrees; fuel heating furnace, refractory clay brick, high alumina brick, silica brick, carborundum brick, refractory castable, the plastic refractory of 1300 degrees; heat treatment furnace, refractory clay brick, refractory fiber of 1100 degrees; high temperature salt bath furnace, refractory clay brick, high alumina brick, zircon brick, refractory castable of 1300 degrees; high temperature resistance furnace, lightweight refractory brick, high aluminum bricks, lightweight alumina brick, lightweight refractory clay brick of 1400 degrees; molybdenum wire furnace, alumina brick, corundum brick, carborundum brick, finished alumina hollow ball product of 1650 degrees; cupola, refractory clay brick, carborundum brick, dolomite Brick, carbon brick, graphite brick of 1650 degrees; arc furnac, high alumina brick, silica brick, magnesia brick, magnesia brick, magnesia chrome... Corundum brick, carbon brick, magnesia chrome brick, magnesia brick, high aluminum brick, silica brick, finished alumina hollow ball product of 1700 degrees; cupola, refractory clay brick of 1650 degrees;

- Q: Can someone tell me the refractory brick in the boiler mixed with what material to build the wall, and what proportion?

- Go to the refractory factory to buy some refractory clay that has the same texture of refractory bricks, the general boiler use clay refractory mortar.

- Q: Are there any good improvement measures for the always collapse of the previous vaulted tunnel kiln built by refractory bricks?

- refractory castable integrally casting

- Q: What is the problem about splintering when the refractory brick is fired?

- There are many bubbles inside the refractory brick, it is also possible that the brick itself is not up to the standard about volume density, then refractory brick fragmentates. There are many reasons, may be in the process of repression

- Q: should clay or refractory cement be used to lay refractory bricks?

- structure strength of this brick lining is not good, apply some refractory mud, only use some virgin clay and corundum, many of the traditional approaches are very simple, mullite and carbon slurry, the specific products are selected according to the selected material and water glass or organic binder. binding agent can choose phosphate, silica and high alumina, clay is one part of the refractory clay, there are many kinds of refractory slurry according to the material, clay-based mud does use refractory cement and corrosion resistance is low

- Q: What are the differences between fired brick and clay brick?

- . Sintered brick is mainly different from cement bricks and so on, not burning bricks at high temperature. Clay fired brick is widely used in paving roads, pavements and clean walls.

- Q: What is the life of an old fashioned refractory brick kiln transformed into a flat topped tunnel kiln? what material should be used to transform the old fashioned refractory bricks vault kiln to flat tunnel kiln, and how long is the service life?

- use castable refractory

- Q: What material is good of refractory bricks?

- It can also be divided into a variety of kinds, it mainly depends on where it is used, each has its own advantages, neutral three categories of refractory bricks have a variety of materials

Send your message to us

Fireclay Brick for Refractory Heat Insulation

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 100 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords