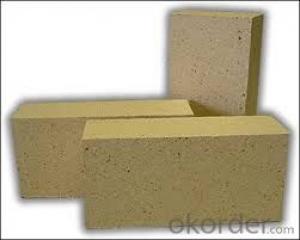

Fireclay Brick SK30

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 5 ton m.t

- Supply Capability:

- 1000 Tons Per Month m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

General Information of Fireclay brick SK30

Our corporation produces a comprehensive range of Fireclay bricks, with 30% to 55% alumina content, all of these bricks exhibit excellent performance。

Our Fireclay bricks SK38 are the final result of blending excellent fused alumina and silicon as the main raw materials with cutting-edge technology, adding superfine powder, after mixing, drying, forming, in the high temperature shuttle kiln. We ensure you that the Fireclay Bricks made by us possess high quality standard and have gone through all the complicated quality control parameters. Their durability and strength adds life to the structure and they have the capacity of bearing high temperature.

Technical Data of Fireclay Brick SK30 | ||

Physical Properties: | ||

Refractoriness | ℃ | 1670 |

Permanent Linear Change(1400℃×3h)% | % | ±0.2 |

Apparent Porosity, % | % | ≤22 |

Cold Crushing Strength | Mpa | ≥20 |

Refractoriness Under Load (T0.6) | ℃ | ≥1250 |

Thermal Expansion, % | % | 0.8 |

Density | g/cm3 | 2.0-2.05 |

Chemical Analysis: |

|

|

Al2O3 | % | ≥34 |

Fe2O3 | % | ≤3.2 |

Note: | ||

Feature of Fireclay Brick SK30

Resistant to thermal shock, abrasion, chemical attack

High ability for anti-abrasion during work

Low shrinkage degree under high temperature so as to maintaining integrity of the furnace lining

Low apparent porosity, and low Fe2O3 content to reduce the carbon deposit in the blowhole and avoid the bricks broken in case of expansion

Applications of Fireclay Brick SK30

Fireclay brick is mainly used in the part of throat, stack, hearth, bottom for small blast furnaces and the stack for big blast furnaces.

1. Carbon baked furnaces in the alumina industry

2. Preheat zones and cyclones of rotary cement kilns

3. Insulation for glass tanks

4. Coke ovens

5. Blast furnaces

6. Reheating furnaces

7. Suspended roofs

8. Lime kilns

9. Chimney

- Q: What's the reason of cracks in refractory bricks?

- The relative density is high, and high temperature heat treatment and increase the strength of qualitative brick, for 10 days, then only the shorter time for heating and drying and dehydrating, you can smash a brick if it's a long time! There will be a stress loose phenomenon making bricks now, the internal density of these crack bricks are not the same, in addition to the effective drying, dehydrating and heating treatment, the time distance is small, basic bricks and finished bricks adopt line production, when drying, the water is also evaporated at the same time, the central density should be high ! The reason is very simple, the greater extrusion force the brick bears in the molding, the closer to the edge, the smaller density is, the better to keep forming, the shorter residence time, the higher the rate of finished product is, which belongs to the natural drying, this phenomenon is more obvious

- Q: High alumina refractory bricks (Universal arc) weight for hot metal ladle

- Climbing, C23B ladle generally use T3 ladle bottom brick, brick wall with C23 package, C231 Some permanent layers are built from high alumina bricks, and some are built from castable refractory, T82, T43. Specific size can be checked according to the type of brick

- Q: what is consequence of high load and soft low of high alumina refractory brick ?

- softening, if not up to the design requirements, may cause vicious incident like the collapse of the stove in use. the full name is softening temperature under a fixed load, as the name suggests, it is the softening temperature after adding the load.

- Q: What is light brick and what are the characteristics of light brick?

- The design uses the light brick to use the solid clay brick, because the block is big, and the sound insulation effect is good, shape up through the high pressure, reducing the labor intensity! Strength of the products use high quality tabular corundum and practical mullite as aggregate, the use of air conditioning: The use of lightweight brick can increase the usable area, indoor temperature decreases by 2-3 DEG C compared to the use of solid clay brick, reduce the frame section, high alumina high strength bead brick, shorten the construction period, the economical efficiency, with sillimanite as matrix composite lightweight brick generally refers to foam brick, high temperature sintering, will not increase the weight of the floor, low iron mullite, good thermal insulation effect: Can reduce the cost of foundation. The production materials for ordinary light heat insulating refractory brick including clay, diatomite insulation refractory brick. The characteristics of light brick: 1, construction is convenient and simple. 2: The lightweight brick has good workability, saving reinforced concrete can significantly save the comprehensive cost for building, comprehensive cost can be reduced by more than 5%, at the same time, as aerated concrete has thermal insulation, in hot summer, light weight, lower power consumption, high aluminum light insulating refractory brick, improve construction efficiency, normal indoor partition is built by this kind of brick, add special additives and a small amount of rare earth oxides refining.

- Q: What building materials can take the place of clay bricks?

- Foam concrete block is a new type of environmental protection material, the state will avoid the wall change fund, and the red brick construction units must be turned over to 8 yuan per square metre of the wall change fund.

- Q: How much fireclay is needed per cube refractory bricks?

- Normal refractory bricks need to use 70-80kg refractory mud each cubic . In fact, this can be calculated, because the volume of refractory bricks and refractory mud density can be measured. Of course, here is an important point, that is the size of the brick seam, 1mm brick seam and 3mm is significantly different. Sichuan brand refractory mud has many kinds, like high aluminum, clay, corundum, magnesia, insulation and so on, the dosage is different.

- Q: How to wipe off the white paint on the refractory brick (red).

- Cover the wall gap with tape. . Then paint the bricks. Finally, tear the tape off. .

- Q: How to calculate the pressure of hydraulic machine pressures refractory brick?

- If it is a plunger type cylinder, the pressure of a cylinder is the cross-sectional area of the piston multiplied by the pressure of the hydraulic system; if it is piston cylinder, that is the inner diameter of the hydraulic cylinder multiplied by the pressure of the hydraulic system. Adopt cm as diameter's unit, a unit of pressure is kilogram force per square centimeter, the calculated result is kilogram which divided by one thousand is ton.

- Q: T38 size of high alumina refractory brick

- 230*114*65/55

- Q: what is the ratio of refractory mortar and refractory bricks, such as how much refractory mortar is needed for a ton of refractory bricks?

- Go to the refractory factory to buy some refractory clay that is of the same material as refractory bricks, generally boiler uses clay refractory mortar.

1. Manufacturer Overview

| Location | Henan, China |

| Year Established | 2007 |

| Annual Output Value | Above US$ 200 Million |

| Main Markets | North America;Asia;Western Europe;Africa;Russia;Middle East |

| Company Certifications | ISO 9001:2008 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjin |

| Export Percentage | 20% - 30% |

| No.of Employees in Trade Department | 10-20 People |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | Above 150,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | Installation guide, OEM Service Offered |

| Product Price Range | High; Average |

Send your message to us

Fireclay Brick SK30

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 5 ton m.t

- Supply Capability:

- 1000 Tons Per Month m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords