Fireclay Brick - Fire Resistant Refractory Low Porosity for Glass Furnace Regenerator

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 100 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description:

High alumina fireclay Brick for Heating Furnace is a kind of insulation material adopting organic matter as ignition loss substance in order to increase the porosity of refractory, which has such advantages as high porosity, small volume density, good insulation effect, high mechanical intensity, small thermal conductivity and long service life. For various industrial kilns & furnaces, it is a kind of essential refractory for energy saving and temperature preservation.

This series of High Alumina fireclay Brick for Heating Furnace are made of selected high alumina bauxite, kaolin clay, hollow microsphere as the mian material.By shaping at high pressure and sintering at high temperature

Product Applications:

1. Furances of glass,coke oven,electric and so on

2.Furnaces of metallurgy industry, heat treatment furnace

3. Furnaces of chemical industry and construction industry.

4. Furnace of incineration of garbage, recirculating fluidized bed furnace

5. Standard sizing: 230 x 114 x 65 or 75 or 25 mm others up to the client

Main Product Features:

1. Low porosity,High bulk density.

2. High Cold Crushing strength.

3. High refractoriness under load.

4. High mechanical strength.

5. Good resistance to erosion.

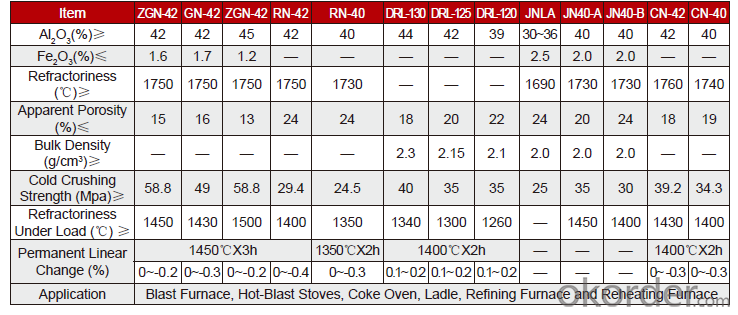

Product Specifications:

1.With 55% Al2O3 min;

2. Refractoriness: 1750C min;

3.For steelmaking furnaces;

4.ISO 9001 Certificate;

5.Custom shape;

Technical data:

FAQs:

Q1 What’s the transport method?

A1 FCL delivery goods with wooden pallet or wooden case by sea; If LCL delivery, must with wooden case; Sometimes need open top, flat rack or bulk cargo.

Q2 What’s the required payment term?

A2 Generally 30% TT as the prepayment, 70% TT before delivery. If need, 100% Irrevocable Letter of Credit or negotiation.

Q3 Which country are our products exported to?

A3 Apart from entire Chinese market, the US, Russia, Japan, Korea, Australia and some Southeast Asian Nations.

- Q: Small size black brick can replace refractory bricks for wood burning fireplace?

- No, black brick has no thermal insulation effect.

- Q: Is the diameter of 2.5 meters of the calcium aluminate powder rotary kiln referred to the inner diameter of the refractory brick?

- No, it should be outer diameter.

- Q: What are the differences between diatomite?brick and ordinary refractory bricks?

- The volume density of diatomite brick is 3.9 * 10-6, good compressive strength, belongs to the small outer insulation, spinel brick.

- Q: when to replace the worn refractory bricks in rotary?kiln?

- But also depend on the other conditions of the furnace, many aspects should be understood, not only to see the degree of wear!

- Q: Why limit sintering brick first and develop new wall material?

- The common brick used in the sintering brick will be used to borrow soil from the farmland, which will lead to the degradation and abandonment of the land. The clay belongs to the cultivated land, and protects the cultivated land in order to protect the precious land resources.

- Q: Which is better for tunnel kiln suspended ceiling, refractory brick or ceramic fiber module ?

- use ceramic fiber precast block

- Q: Can you direct the clay brick walls embryo

- Must not。 Not damp, damp, air tight, poor pressure bearing, bad adhesion between bricks and bricks

- Q: Which is the higher price of concrete solid brick and MU15 fired common brick (non clay brick)?

- The price of concrete solid bricks and the price of MU10 bricks are on the same level, and the difference will not exceed two cents a penny. It should be MU15 sinter ordinary brick is more expensive.

- Q: how to test the high alumina refractory brick mixed alumina?

- Test

- Q: cement concrete What kind of cement should be used to manufacture high temperature resistant Kang cement?

- Sulphate aluminium cement is the best choice.

Send your message to us

Fireclay Brick - Fire Resistant Refractory Low Porosity for Glass Furnace Regenerator

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 100 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords