High Quality Light Steel Rail for Structure Q235, 55Q

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 200000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

OKorder is offering High Quality Light Steel Rail for Structure Q235, 55Q at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

High Quality Light Steel Rail for Structure Q235, 55Q is mainly used in forest region, mines, factories and construction sites laid of the place such as temporary transport line and light motorcycles with line, for example: railway, subway, transportation track, express, curve way, tunnel way.

Product Advantages:

OKorder's High Quality Light Steel Rail for Structure Q235, 55Q are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Description of High Quality Light Steel Rail for Structure Q235, 55Q:

Specifications of High Quality Light Steel Rail for Structure Q235, 55Q

Production Standard: GB11264-89

Material: Q235, 55Q

Grade | Element(%) | ||||

C | Mn | S

| P

| Si

| |

Q235 |

0.12—0.20 |

0.3—0.7 |

≤0.045 |

≤0.045

|

≤0.3

|

55Q | 0.50—0.60 | 0.70—1.00 | ≤0.050 | ≤0.045 | 0.15-0.35 |

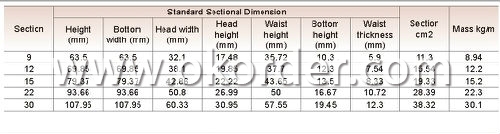

Sizes: 9kg, 12kg, 15kg, 22kg, 30kg

Length: 6M, 8M, 10M, 12M or as the requriement

Invoicing on theoretical weight or actual weight as customer request

Payment terms: 30% advance payment by T/T, 70% payment against the copy of the B/L; 100% L/C at sight, etc.

Package & Delivery of Ms Light Steel Rail Q235, 55Q

1. Package: it is nude packed in bundles by steel wire rod

2. Bundle weight: not more than 3.5MT for bulk vessel; less than 3 MT for container load

3. Marks:

Color marking: There will be color marking on both end of the bundle for the cargo delivered by bulk vessel. That makes it easily to distinguish at the destination port.

Tag mark: there will be tag mark tied up on the bundles. The information usually including supplier logo and name, product name, made in China, shipping marks and other information request by the customer.

If loading by container the marking is not needed, but we will prepare it as customer request.

4. Transportation: the goods are delivered by truck from mill to loading port, the maximum quantity can be loaded is around 40MTs by each truck. If the order quantity cannot reach the full truck loaded, the transportation cost per ton will be little higher than full load.

5. Delivered by container or bulk vessel

6. Delivery Time: All the High Quality Light Steel Rail for Structure Q235, 55Q will be transpoted at the port of Tianjin, China within 30 days after receiving the advance payment by T/T or the orginal L/C at sight.

Production flow of Ms Light Steel Rail Q235, 55Q

Material prepare (billet) —heat up—rough rolling—precision rolling—cooling—packing—storage and transportation

Inspection of Ms Light Steel Rail Q235, 55Q

We will send the MTC of the factory to the clients directly which contains the anlisis of the heat, chemiqual composition, phisical characteristicas, etc.

FAQ:

Q1: What is the normal tolerance of High Quality Light Steel Rail for Structure Q235, 55Q?

A1: Normally 3%-5%, but we can also produce the goods according to the customers' requests.

Q2: Can fit in the containers of 20fts the steel beams of High Quality Light Steel Rail for Structure Q235, 55Q?

A2: No proble, we can put them into the containers in the form sideling.

Q3: The products are invoicing on theoritical weight or on actual weight?

A3: We can do it in both manners, according to the customers' request.

- Q:Can steel rails be customized for specific applications?

- Yes, steel rails can be customized for specific applications. The dimensions, shape, and composition of the steel rails can be modified to meet the specific requirements of different applications, such as heavy-duty railway tracks, tram systems, or industrial tracks. Customization allows for enhanced performance, durability, and safety in various industries and transportation systems.

- Q:How do steel rails handle changes in train speeds?

- Steel rails are designed to handle changes in train speeds by providing a stable and smooth surface for the train wheels. The strength and durability of steel allow the rails to withstand the forces exerted by trains accelerating, decelerating, or changing direction. Additionally, rail tracks are carefully aligned and maintained to ensure proper alignment and reduce the impact of speed changes on the train's stability and ride quality.

- Q:How do steel rails perform under heavy axle loads?

- Steel rails are designed to withstand heavy axle loads and perform exceptionally well under such conditions. The strength and durability of steel make it an ideal material for rail infrastructure. When subjected to heavy axle loads, steel rails distribute the weight evenly across their length, minimizing the impact on the track structure. One of the main advantages of steel rails is their high load-bearing capacity. They can handle the weight of heavy trains without significant deformation or damage. This is particularly important in modern railway systems, where freight trains and high-speed trains often have heavier axle loads. Steel rails also exhibit excellent resistance to fatigue. Fatigue failure occurs when materials are subjected to repeated loading and unloading, which can cause cracks and fractures over time. However, steel rails are specifically designed to withstand the cyclic loading associated with heavy axle loads, ensuring long-term durability and performance. Furthermore, steel rails offer superior wear resistance. The continuous contact between the steel wheel and the rail can lead to gradual wear. However, steel rails are manufactured with high-quality steel alloys that provide resistance against wear and minimize the need for frequent maintenance. To ensure optimal performance under heavy axle loads, regular inspection and maintenance of steel rails are necessary. This includes monitoring the condition of the rails, checking for any signs of wear or damage, and addressing any maintenance issues promptly. By following proper maintenance protocols, steel rails can continue to perform reliably and safely, even under heavy axle loads.

- Q:How are steel rails protected from excessive noise?

- Steel rails can be protected from excessive noise through various methods. One common approach is the use of rail dampers or rail pads. These are resilient materials placed between the rail and the sleeper, absorbing and reducing vibrations and noise generated by passing trains. Rail dampers can be made of rubber or other elastomeric materials, effectively isolating the rail from the sleeper and reducing noise transmission. Additionally, rail grinding is another technique employed to control noise. It involves removing irregularities and imperfections on the surface of the rail, which can cause increased noise levels. Grinding smoothens the rail, reducing friction and minimizing noise produced during train operations. Moreover, rail fasteners play a crucial role in noise reduction. Modern rail fastening systems, such as resilient fasteners or elastic clips, are designed to absorb and dampen vibrations. These fasteners provide flexibility to the rail, allowing it to absorb energy and reducing noise transmission. Furthermore, the use of noise barriers alongside railway tracks can significantly reduce noise pollution. These barriers, made of materials like concrete or metal, act as sound-absorbing walls, blocking or deflecting noise generated by passing trains. Overall, a combination of rail dampers, rail grinding, resilient fasteners, and noise barriers helps protect steel rails from excessive noise. These measures aim to minimize vibrations, absorb energy, and create barriers to noise transmission, ensuring a quieter and more comfortable environment for both nearby residents and passengers.

- Q:What are the specifications for steel rail trackside equipment?

- The specifications for steel rail trackside equipment vary depending on the specific requirements of the project or application. However, some common specifications include the material composition of the steel, such as its grade and strength, the dimensions and tolerances of the equipment, and any additional features or certifications required for safety and compatibility with the rail infrastructure. It is important to consult the relevant industry standards and guidelines, as well as the specific project requirements, to determine the appropriate specifications for steel rail trackside equipment.

- Q:What is the cost of steel rails compared to other rail materials?

- The cost of steel rails is generally higher compared to other rail materials such as concrete or wood. However, steel rails offer superior durability, strength, and longevity, which can result in long-term cost savings due to reduced maintenance and replacement needs.

- Q:How do steel rails contribute to noise reduction in railway tracks?

- Steel rails contribute to noise reduction in railway tracks through their characteristics and design. Steel rails have a smooth and hard surface, which reduces friction and vibrations caused by train wheels. This reduces the overall noise generated by the train as it moves over the tracks. Additionally, steel rails are designed to be sturdy and secure, preventing any loose or shaky connections between the tracks. This stability further minimizes noise by preventing any unnecessary movement or rattling of the tracks.

- Q:How do steel rails handle changes in train direction?

- Steel rails are designed to handle changes in train direction by providing a smooth and stable track surface. The rails are securely fastened to the sleepers, which help distribute the weight of the train evenly. This allows the wheels to smoothly transition from one direction to another without causing any significant disruptions or derailments. Additionally, the use of steel as the rail material ensures its strength and durability, enabling it to withstand the forces exerted by the train during directional changes.

- Q:Can steel rails be used for roller coasters?

- Yes, steel rails can be used for roller coasters. In fact, steel is the most commonly used material for roller coaster tracks due to its strength, durability, and ability to withstand the intense forces and high speeds experienced by roller coasters.

- Q:What are the noise reduction benefits of using steel rails?

- The noise reduction benefits of using steel rails include the ability to dampen vibrations and absorb sound, resulting in quieter train operations. Steel rails also offer a smoother surface for trains to travel on, minimizing friction and reducing noise levels.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

High Quality Light Steel Rail for Structure Q235, 55Q

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 200000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords