Five Bar Treadplate Aluminium Panel 3003 H14 for Tool Box

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

1. Specification of Five Bar Treadplate Aluminium Panel 3003 H14 for Tool Box

Alloy Number | AA1XXX,AA3XXX,AA5XXX |

Temper | H12, H14, H16, H18, H22, H24, H26, H32, HO, F |

Thickness | 0.1mm – 500mm |

Width | 10mm- 2200mm |

Standard | GB/T3880-2006, ASTM, ISO, EU standard |

2. Application of Five Bar Treadplate Aluminium Panel 3003 H14 for Tool Box

Transfporation, vehicle, antiskid plate,toolbox,canopy body,

3. Feature of Five Bar Treadplate Aluminium Panel 3003 H14 for Tool Box

Surfact Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mechenical Property:

Chemical Composite and Mechanical Property

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

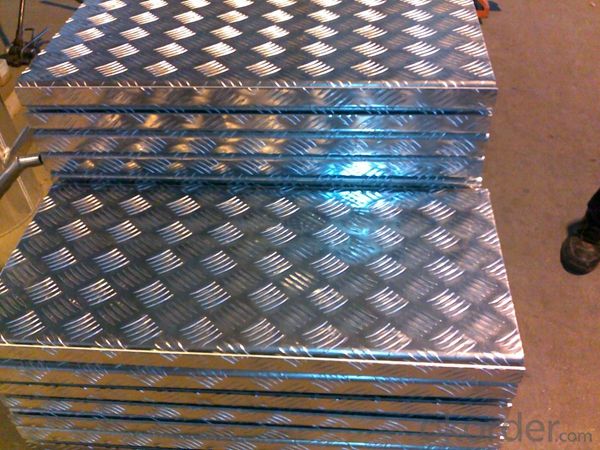

5. Image of Five Bar Treadplate Aluminium Panel 3003 H14 for Tool Box

6. Package and shipping of Five Bar Treadplate Aluminium Panel 3003 H14 for Tool Box

First, plastic cloth with drying agent inside; Second, Pearl Wool ; Third, wooden cases with dry agent , fumigation wooden pallets, aluminum surface could cover blue PVC film

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q:which kind of material won't influence magnet attracting iron nail? Does copper sheet or aluminum sheet influence it?

- Copper coil will impede magnetic penetration. People separate the magnet from the workpiece of machine tool to avoid magnetic short circuit and attraction loss, making magnetic line of force go through the workpiece. An opening copper bush is added into the iron core of magnetic closing coil or opening solenoid to avoid the iron core being attracted on the external iron piece and stop operation. The opening is for avoiding eddy formulation and short circuit, iron core in copper bush is the ruled magnetic circuit.

- Q:Can the aluminum sheets be used in marine environments?

- Yes, aluminum sheets can be used in marine environments. Aluminum is a popular choice for marine applications due to its excellent corrosion resistance. Unlike other metals, aluminum forms a protective oxide layer on its surface when exposed to oxygen, preventing further corrosion. This makes it ideal for use in saltwater environments where the risk of rusting and corrosion is high. Additionally, aluminum is lightweight, durable, and has a high strength-to-weight ratio, making it suitable for various marine applications such as boat hulls, shipbuilding, offshore platforms, and other marine structures.

- Q:Can aluminum sheet be used for automotive body panels?

- Automotive body panels can indeed utilize aluminum sheets. In fact, aluminum is gaining popularity in the automotive industry due to its numerous advantages. Firstly, aluminum surpasses steel in terms of weight, leading to improved fuel efficiency and overall vehicle performance. Furthermore, aluminum boasts high resistance to corrosion, providing durability for body panels exposed to the elements. Additionally, aluminum exhibits remarkable formability, enabling the creation of intricate designs and enhancing design flexibility during vehicle production. Moreover, aluminum excels in absorbing crash impact, thereby enhancing vehicle safety. Nevertheless, it is important to acknowledge that utilizing aluminum for automotive body panels may necessitate specialized equipment and techniques for welding and repair purposes.

- Q:What is the typical thickness tolerance for aluminum sheets?

- The typical thickness tolerance for aluminum sheets can vary depending on the specific application and industry standards. However, in general, the accepted thickness tolerance range for aluminum sheets is typically within ± 0.005 to ± 0.015 inches. This means that the actual thickness of the sheet may vary within this tolerance range from the specified thickness. It is important to note that different industries may have different tolerance requirements based on the intended use of the aluminum sheet, so it is always advisable to consult the relevant industry standards or specifications for specific tolerance requirements.

- Q:Are the aluminum sheets suitable for aerospace applications?

- Yes, aluminum sheets are suitable for aerospace applications. Aluminum is widely used in the aerospace industry due to its excellent strength-to-weight ratio, corrosion resistance, and high thermal conductivity. These properties make it an ideal material for manufacturing aircraft structures, such as fuselages, wings, and structural components. Additionally, aluminum can be easily machined and formed into complex shapes, allowing for the production of lightweight and aerodynamic structures. Furthermore, aluminum sheets can be easily joined using various techniques, including welding and riveting, ensuring the structural integrity of aerospace components. Overall, aluminum sheets are well-suited for aerospace applications and have been extensively utilized in the industry for many years.

- Q:Is aluminum sheet fire-resistant?

- No, aluminum sheet is not inherently fire-resistant. However, it does have a relatively high melting point and can conduct heat well, which can help slow down the spread of fire.

- Q:Can aluminum sheet be used for electrical wiring?

- No, aluminum sheet cannot be used for electrical wiring.

- Q:How do aluminum sheets perform in terms of dimensional stability?

- Aluminum sheets generally exhibit good dimensional stability due to their low coefficient of thermal expansion, meaning they are less likely to warp or deform when exposed to temperature changes compared to other materials.

- Q:Can 101 aluminum sheets be used in electrical or electronic components?

- Yes, 101 aluminum sheets can be used in electrical or electronic components. Aluminum is a versatile metal that possesses excellent electrical conductivity and is widely used in various electrical and electronic applications. It is commonly used as a conductor in power transmission lines, electrical cables, and wiring. Additionally, aluminum sheets can be used in the manufacturing of electronic components such as heat sinks, circuit boards, and enclosures due to their lightweight, corrosion-resistant, and thermally conductive properties. However, it is important to note that the specific grade and alloy of aluminum, as well as other factors such as thickness and surface treatment, may also influence its suitability for certain electrical or electronic applications.

- Q:Can aluminum sheet be used for electrical enclosures?

- Yes, aluminum sheet can be used for electrical enclosures. Aluminum is a popular choice for electrical enclosures due to its excellent conductivity, lightweight nature, and corrosion resistance. It provides effective shielding against electromagnetic interference and offers good heat dissipation properties. Additionally, aluminum is easily formable, allowing for the creation of complex shapes and designs. Overall, aluminum sheet is a suitable material for electrical enclosures and is commonly used in various industries including electronics, telecommunications, and power distribution.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Five Bar Treadplate Aluminium Panel 3003 H14 for Tool Box

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords