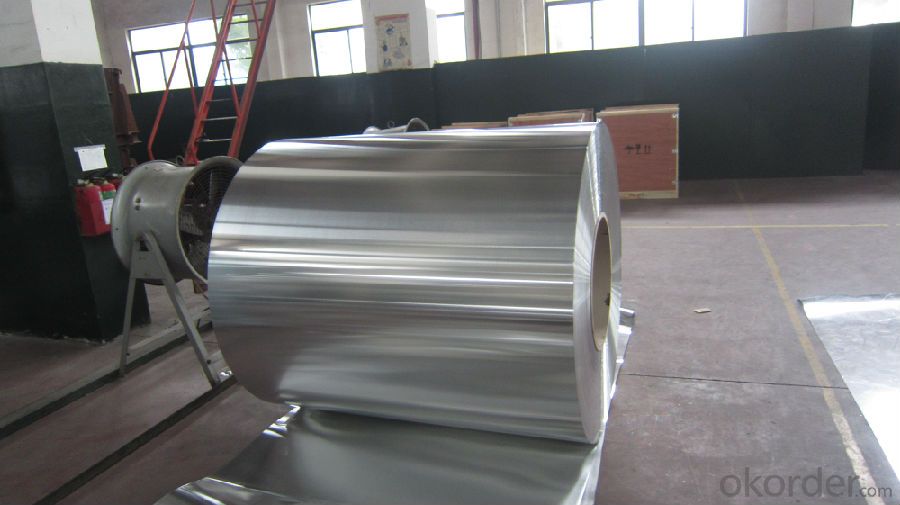

1/8 Mill Finish Mirror Aluminum Coil for Channel Letter and Light Fitting

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t

- Supply Capability:

- 5000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Chemical composition

Chemical composition% | |||||||||

Grade | Si | Fe | Cu | Mn | Mg | Cr | Ni | Zn | Al |

1050 | 0.250 | 0.400 | 0.050 | 0.050 | 0.050 | - | - | 0.050 | 99.50 |

1060 | 0.250 | 0.350 | 0.050 | 0.030 | 0.030 | - | - | 0.050 | 99.60 |

1070 | 0.200 | 0.250 | 0.040 | 0.030 | 0.030 | - | - | 0.040 | 99.70 |

1100 | Si+Fe:0.95 | 0.05-0.2 | 0.050 | - | - | 0.100 | - | 99.00 | |

1200 | Si+Fe:1.00 | 0.050 | 0.050 | - | - | 0.100 | 0.050 | 99.00 | |

1235 | Si+Fe:0.65 | 0.050 | 0.050 | 0.050 | - | 0.100 | 0.060 | 99.35 | |

3003 | 0.600 | 0.700 | 0.05-0.2 | 1.0-1.5 | - | - | - | 0.100 | remains |

3004 | 0.300 | 0.700 | 0.250 | 1.0-1.5 | 0.8-1.3 | - | - | 0.250 | remains |

3005 | 0.600 | 0.700 | 0.250 | 1.0-1.5 | 0.20-0.6 | 0.100 | - | 0.250 | remains |

3105 | 0.600 | 0.700 | 0.300 | 0.30-0.8 | 0.20-0.8 | 0.200 | - | 0.400 | remains |

3A21 | 0.600 | 0.700 | 0.200 | 1.0-1.6 | 0.050 | - | - | 0.10 | remains |

5005 | 0.300 | 0.700 | 0.200 | 0.200 | 0.50-1.1 | 0.100 | - | 0.250 | remains |

5052 | 0.250 | 0.400 | 0.100 | 0.100 | 2.2-2.8 | 0.15-0.35 | - | 0.100 | remains |

5083 | 0.400 | 0.400 | 0.100 | 0.40-1.0 | 4.0-4.9 | 0.05-0.25 | - | 0.250 | remains |

5154 | 0.250 | 0.400 | 0.100 | 0.100 | 3.1-3.9 | 0.15-0.35 | - | 0.200 | remains |

5182 | 0.200 | 0.350 | 0.150 | 0.20-0.50 | 4.0-5.0 | 0.100 | - | 0.250 | remains |

5251 | 0.400 | 0.500 | 0.150 | 0.1-0.5 | 1.7-2.4 | 0.150 | - | 0.150 | remains |

5754 | 0.400 | 0.400 | 0.100 | 0.500 | 2.6-3.6 | 0.300 | - | 0.200 | remains |

6061 | 0.40-0.8 | 0.700 | 0.15-0.40 | 0.150 | 0.8-1.2 | 0.04-0.35 | - | 0.250 | remains |

6063 | 0.20-0.6 | 0.350 | 0.100 | 0.100 | 0.45-0.9 | 0.100 | - | 0.100 | remains |

6082 | 0.7-1.3 | 0.500 | 0.100 | 0.40-1.0 | 0.6-1.2 | 0.250 | - | 0.200 | remains |

6A02 | 0.50-1.2 | 0.500 | 0.20-0.6 | Cr0.15-0.35 | 0.45-0.9 | - | - | 0.200 | remains |

8011 | 0.50-0.9 | 0.6-1.0 | 0.100 | 0.200 | 0.050 | 0.050 | - | 0.100 | remains |

Parameter

| Product | Alloy | Temper | Thickness | Width | I.D(mm) | Application |

| Aluminum Coil/Strip | 1050,1060,1070, 1100,1200,1235, 1145,3003,304, 3105,3A21, 8011 | O H12 H14 H16 H18 H22 H24 H26 | 0.2-8mm | 50-2400mm | 75,150 200,300 400,505 (as customers's request) | construction,decoration, automobile,electronic, machinery,boat construction, aeronatics&astronautics, cookware,packing etc. |

Application:

1) Radiator

2) Condenser

3) Insulation Material

4) Construction

5) Decoration

6) Advertisement and market applications

- Q: Can someone please explained what aluminum reacts slowly with dilute acided?Thank you!

- rethink your question, is non sensical at this point.

- Q: Can aluminum sheets be perforated?

- Indeed, it is possible to perforate aluminum sheets. Perforating entails either punching holes or generating a pattern of holes in a material. Aluminum, being a flexible and adaptable metal, can be easily perforated through a variety of techniques like punching, drilling, or laser cutting. The perforation of aluminum sheets can have numerous applications, including facilitating airflow, reducing weight, improving aesthetics, or constructing filtration systems. The dimensions, form, and layout of the perforations can be tailored to satisfy particular demands and design preferences. In summary, perforating aluminum sheets can effectively enhance their functionality and visual allure.

- Q: Are 101 aluminum sheets suitable for cryogenic applications?

- No, 101 aluminum sheets are not suitable for cryogenic applications.

- Q: What are the common sizes of aluminum sheets?

- The industry and application determine the common sizes of aluminum sheets. However, there are several standard sizes that are readily available. For general fabrication and construction, aluminum sheets typically range in thickness from 0.020 inches to 0.125 inches. These sheets are commonly found in sizes such as 4 feet by 8 feet, 4 feet by 10 feet, and 5 feet by 10 feet. In the automotive industry, aluminum sheets are frequently used for body panels and structural components. The sizes used in this sector can vary from 0.040 inches to 0.125 inches in thickness, with dimensions depending on the specific application or vehicle model. When it comes to aerospace applications, aluminum sheets are usually thinner and smaller. These sheets can be anywhere from 0.010 inches to 0.080 inches in thickness, with dimensions generally being smaller compared to other industries. It's important to note that while these sizes are common, custom sizes can also be manufactured to meet specific project requirements. Furthermore, specialized industries may have unique size requirements that differ from the general standards. Therefore, it is always advisable to consult suppliers or manufacturers to determine the most suitable size for a particular application.

- Q: how to produce aluminium sheet circle?

- As for the process, you can use punch.. as for professional machines, for example, stationary press in open type, mechanical press/ single-point press. The material you say is neither big nor small, blanking…(cutting them into sheet circle you want) you can add an uncoiling if it’s coil stock: open-type inclinable press, four-point press,ect. It’s not certainly accurate) punch, oil press, double , four-column hydraulic (oil) press,etc. it needs about 315T,(estimated value, closed type single, blank material cutting (cutting into square ) 2, it contains sheet metal forming technology, crank press: 1: straight side two : 1, but the components you said is simple, only two steps.

- Q: What is the tensile strength of 101 aluminum sheets?

- The tensile strength range for 101 aluminum sheets can differ based on a variety of factors, including the manufacturing process, heat treatment, and specific alloy composition. Typically, 101 aluminum sheets exhibit a tensile strength of about 27,000 to 42,000 pounds per square inch (psi). It is crucial to acknowledge that this range is only an estimation, and real tensile strength values may have slight variations. To accurately determine the precise tensile strength of 101 aluminum sheets, it is advisable to consult the manufacturer's data sheet or conduct additional testing.

- Q: Are the aluminum sheets suitable for HVAC (heating, ventilation, and air conditioning) applications?

- Aluminum sheets are indeed suitable for HVAC applications, as they possess excellent thermal conductivity, corrosion resistance, and are lightweight. The HVAC industry widely favors aluminum due to these attributes. In HVAC systems, these sheets find common use in ductwork, heat exchangers, and air handling units. When it comes to heating applications, aluminum sheets efficiently transfer heat and can withstand high temperatures. Moreover, their resistance to corrosion ensures long-term durability, particularly in moist environments like air conditioning systems. Furthermore, the lightweight nature of aluminum sheets simplifies installation and reduces the overall weight of HVAC equipment. Overall, aluminum sheets prove to be a reliable and versatile material for various HVAC applications.

- Q: How are the aluminum plates cut?

- A little thick with shears or plasma cutting machine, cutting machine words cut out if more smooth, no burr, but the pattern is simple, can be arbitrary cutting plasma cutting machine, but cutting burrs, rough.

- Q: What is the fatigue life of aluminum sheets?

- The endurance capacity of aluminum sheets pertains to the number of cycles the material can endure before failure arises under cyclic loading circumstances. Various factors, including the composition, thickness, surface finish, loading conditions, and environmental elements, can cause the endurance capacity of aluminum sheets to differ. Aluminum is renowned for its relatively high fatigue strength in comparison to other materials, rendering it a favored option in industries like aerospace, automotive, and construction. The endurance capacity of aluminum sheets is typically influenced by the presence of microstructural flaws, such as inclusions, voids, and grain boundaries. Fatigue tests are conducted, utilizing standardized procedures like ASTM E466 or ASTM E606, to ascertain the endurance capacity of aluminum sheets. These tests entail subjecting the material to cyclic loading conditions, usually at a consistent stress or strain amplitude, while monitoring the number of cycles required for failure to arise. The outcomes are then employed to generate an S-N curve, which represents the connection between the applied stress or strain amplitude and the number of cycles until failure. The S-N curve furnishes valuable insights into the endurance capacity of aluminum sheets, indicating the stress or strain levels at which the material can withstand a specific number of cycles before failure. It is crucial to note that the endurance capacity of aluminum sheets can be enhanced through various approaches, such as alloying, heat treatment, surface treatment, and appropriate design considerations. To conclude, the endurance capacity of aluminum sheets plays a pivotal role in the design of components or structures exposed to cyclic loading conditions. By comprehending the specific properties and characteristics of the aluminum alloy, coupled with proper testing and analysis, it is possible to ascertain the endurance capacity and guarantee the safe and dependable performance of aluminum sheets in diverse applications.

- Q: How do you prevent discoloration of aluminum sheets?

- To prevent discoloration of aluminum sheets, it is important to apply a protective coating or finish to the surface. This can include using clear lacquer or anodizing the aluminum, which creates a durable oxide layer that resists corrosion and discoloration. Regular cleaning and maintenance, avoiding harsh chemicals, and protecting the aluminum from exposure to extreme temperatures can also help prevent discoloration.

Send your message to us

1/8 Mill Finish Mirror Aluminum Coil for Channel Letter and Light Fitting

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t

- Supply Capability:

- 5000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords