5052 Mill Finish Mirror Aluminum Coil for Channel Letter

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Mill Finish Mirror Aluminium Coil for Channel Letter

Thickness | 0.1mm-10mm |

Popular Thickness | 0.1mm/0.2mm/0.25mm/0.3mm/0.6mm/0.8mm/1.0mm/1.2mm/1.5mm/2.0mm/3.0mm... |

Width | 20mm-2500mm |

inner diameter | 505mm 508mm 605mm |

Material | 1050,1060,1070,1100,1200,3003,3004,3005,5052,5005,5754,5083 |

Temper | O,H12,H14,H16,H18,H22,H24,H26,H32,H34,H36,H38,H111,H112 |

Surface | mill finish |

Packing | Export standard wooden pallets |

Payment Terms | 100% irrevocable L/C at sight or 30% T/T in advance as deposit,70% balance against the B/L copy |

Minimum Order Quantity | 5000kg |

Delivery time | 15-25 days after receiving L/C or deposit |

Remark | Specific requirement of alloy grade, temper or specification can be discussed at your request |

2. Application of Mill Finish Mirror Aluminium Coil for Channel Letter

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of PVDF Painted Aluminum Coil Competitive Price and BEST Manufacture and factor

*Such coil is specially designed to replace aluminum ingot, due to the high export tax of aluminum ingot, the coil has better price than ingot.

*This type of coil can fit customer's remelting furnace just like ingot, no need to make any change to the production line that was previously used for ingot. The standard coil size and weight is very suitable for the feed gate of furnace.

*This type of coil causes less material wastage than ingot when remelted.

*Our coil is made directly from ore, no need to go though the ingot making process, quality is much better than other suppliers who use ingot scrap to make coil.

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

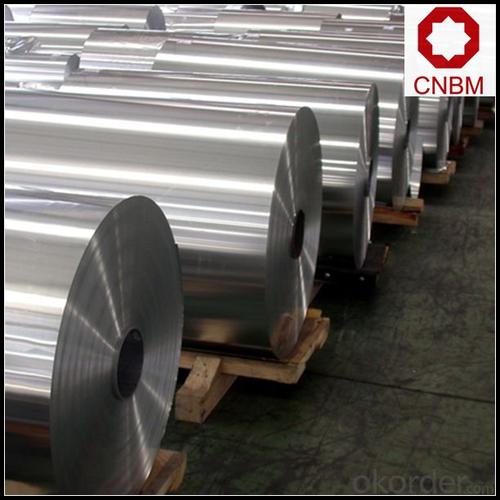

5. Image of Mill Finish Mirror Aluminium Coil for Channel Letter

6. Package and shipping of Mill Finish Mirror Aluminium Coil for Channel Letter

eye to wall

eye to the wall

with wood pallet (wooded case also available)

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: What are the potential environmental impacts of aluminum coil production?

- The potential environmental impacts of aluminum coil production include deforestation due to the extraction of bauxite, water pollution from the chemicals used in the refining process, air pollution from the release of greenhouse gases during smelting, and energy consumption, as aluminum production requires a significant amount of electricity. Additionally, the disposal of waste materials and by-products can contribute to soil contamination if not managed properly.

- Q: Can aluminum coils be used for packaging applications?

- Indeed, packaging applications can make use of aluminum coils. Aluminum, being a versatile material, possesses various advantageous properties for packaging purposes. Its lightweight nature, resistance to corrosion, non-toxicity, and exceptional thermal conductivity are just a few of the many benefits it offers. These qualities render aluminum coils perfect for packaging applications such as food and beverage containers, pharmaceutical packaging, and cosmetic packaging. Moreover, aluminum can easily be molded into various shapes and sizes, allowing for tailor-made packaging solutions. Its durability ensures the safeguarding of the packaged goods, while its ability to be recycled makes it an environmentally conscious choice. In summary, the versatility, performance, and sustainability of aluminum coils make them extensively utilized in packaging applications.

- Q: Are aluminum coils suitable for solar panel frames?

- Indeed, solar panel frames can be made from aluminum coils. Aluminum, being both lightweight and resistant to corrosion, is an optimal choice for constructing solar panel frames. Moreover, its exceptional durability enables it to endure diverse weather conditions, ultimately ensuring the prolonged lifespan of the solar panel structure. Furthermore, aluminum possesses excellent heat dissipation properties and is effortless to manipulate, which is vital for solar panels as they generate heat whilst operating. By utilizing aluminum coils in solar panel frames, the efficiency and performance of the entire solar panel system can be significantly improved.

- Q: Are aluminum coils suitable for interior decorative applications?

- Yes, aluminum coils are suitable for interior decorative applications. Aluminum is a lightweight and versatile material that can be easily shaped into various forms, making it ideal for decorative purposes. It also comes in a wide range of finishes, colors, and patterns, allowing for endless design possibilities. Additionally, aluminum is highly durable and resistant to corrosion, ensuring that it will maintain its aesthetic appeal over time. Moreover, aluminum is a sustainable material, as it can be recycled indefinitely, making it an environmentally friendly choice for interior decorations. Overall, aluminum coils provide a cost-effective and aesthetically pleasing option for interior decorative applications.

- Q: The user is inquiring about the possibility of reusing their old aluminum coils or purchasing used ones.

- <p>Yes, you can reuse your old aluminum coils if they are still in good condition and meet the required specifications for your application. Reusing can be cost-effective and environmentally friendly. When buying used coils, ensure they are from a reputable source and have been properly inspected for any damage or wear that could affect performance. It's crucial to verify the coils' integrity and functionality before use to avoid any potential issues in your manufacturing or production process.</p>

- Q: Can the 5-10cm thick paper sleeve inside the scrapped aluminum coil be sliced? Now we use knife which is much troublesome.

- You can use Long Men Rolling Mill to slice directly.

- Q: How do aluminum coils perform under low-temperature applications?

- Aluminum coils generally perform well under low-temperature applications due to the metal's high thermal conductivity and excellent resistance to low temperatures. This allows the coils to efficiently transfer and distribute heat, making them suitable for various cooling and refrigeration systems. Additionally, aluminum's natural corrosion resistance helps maintain the coils' performance and durability in low-temperature environments.

- Q: How are aluminum coils used in the production of gutters and downspouts?

- Aluminum coils play a crucial role in the production of gutters and downspouts. These coils are used as the primary material to manufacture seamless gutters, which are known for their durability, longevity, and aesthetic appeal. To begin the production process, the aluminum coils are fed into a specialized gutter machine. This machine shapes the coils into the desired gutter profile, typically in the form of a long continuous piece. The coil is then cut into appropriate lengths to match the measurements of the gutter system required for a specific building or project. Once cut, the aluminum coil is then shaped and formed using various bending and folding techniques. This allows the coil to be transformed into the seamless gutter shape needed to efficiently collect and channel rainwater away from the roof and foundation of a building. The seamless design eliminates the risk of leaks and enhances the overall functionality of the gutter system. Additionally, the aluminum coils used in gutter production offer several advantages. Firstly, aluminum is lightweight yet sturdy, making it an ideal material for gutters and downspouts. It is resistant to rust and corrosion, ensuring the longevity of the gutter system even in harsh weather conditions. Furthermore, aluminum is highly malleable, allowing for customized shapes and sizes to fit the specific requirements of different buildings. In conclusion, aluminum coils are an integral component in the production of gutters and downspouts. They are used to create seamless gutters that are aesthetically pleasing, durable, and highly functional. The use of aluminum as the primary material ensures long-lasting performance, resistance to corrosion, and customization options for various architectural needs.

- Q: Can aluminum coils be used in electrical cables?

- Yes, aluminum coils can be used in electrical cables. Aluminum is commonly used as a conductor in high-voltage power transmission cables due to its lighter weight and lower cost compared to copper. However, it is important to note that aluminum has higher resistivity than copper, so larger cross-sectional areas are required to achieve the same level of conductivity. Additionally, special connectors and jointing techniques are necessary to account for the differences in thermal expansion and electrical conductivity between aluminum and other materials used in electrical systems.

- Q: ... of aluminum atoms?(mole = 6.022x10^23)

- Believe it or not, you have the proverbial not enough information in this problem. That's because you don't specify the thickness of the aluminum foil. You will certainly need to know that before you can determine the volume of Al and the number of atoms. You will also need the density of Al, but that's easy enough to come by. Just for grins, say the foil is 0.0020 cm thick, and the density of Al foil is 2.70 g/cm^3. If you have an Avogadro's number of Al atoms (1 mole), then you have 27.0 grams of Al (molar mass of Al). If the density of aluminum is 2.7 g/cm^3, then you have a piece of aluminum with a volume of 10.0 cm^3. V = L x W x H .... where H is the thickness of the foil You are given the width and have looked up a thickness, and have calculated the volume. So solve for length. L = V / (WH) = 10 cm^3 / (30.48 cm x 0.0020 cm) L = 164 cm You would need a section of foil 164 cm long to give you approximately 1 mol of aluminum atoms if the thickness is 0.02 mm.

Send your message to us

5052 Mill Finish Mirror Aluminum Coil for Channel Letter

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords