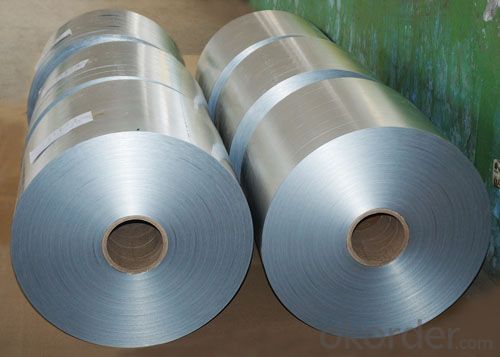

Painted Aluminum Coils - 1050 1060 3003 3105 5005 5052 8011 for Channel Letter

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 6000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1050 1060 3003 3105 5005 5052 8011Aluminum Coil for Channel Letter

Packaging & Delivery

Name | 3003 Aluminum Coil |

ALloy or Not | Yes |

Alloy | 1100H-18, 3003-H24,3003-H26,3005-H26,8011,3004,3105,5005,etc. |

Thickness | 0.1~1.5mm |

Width | <2000mm< span=""> |

MOQ | 1 MT |

Coating finish | Brushed, drawing, embossed, printing |

Color | As to code RAL |

Surface | Embossed,Mill Finish,Coated,Brushed |

Gloss | 10-90%(EN ISO-2813:1994) |

Total coating thick | PVDF27 ~35micron |

Polyester18~27micron(EN ISO-2360:1995) | |

Coating hardness | 2H |

Adhesion | 5B (EN ISO-2409:1994) |

Impact resistance | No cracking and peeling (A.S.T.M D2794-1993) |

Flexibility (T-bend) | 0T- 2T |

MEK resistance | 100 |

Certification | ISO9001:2000, CE, SGS |

Coil's standard diameter | 1100mm |

Inner Diameter | 405mm/505mm |

Coil's standard weight | 1MT - 2MT |

Product Specification | |

Grade | 1000 Series: 1050 1060 1100 3000 Series: 3003 3004 3105 5000 Series: 5052 5605,5083 6000 Series: 6061 6063 8000 Series: 8011 8021 8079 |

Thickness | 0.20-8.00mm |

Width | 2400mm max. |

Grade | 1000,3000,5000,6000,8000series |

Coil ID | 75mm, 150mm, 200mm, 300mm, 400mm, 508mm or negotiable |

Coil weight | 1000-5000kgs |

Coil OD | 1700mm max. |

Temper | O, H12, H14, H16, H111, H22 ,H24, H26, H28,T4, T6,etc. |

Chemical Composition | |||||||||

| Grade | Si | Fe | Cu | Mn | Mg | Cr | Ni | Zn | Al |

| 1050 | 0.25 | 0.4 | 0.05 | 0.05 | 0.05 | - | - | 0.05 | 99.5 |

| 1060 | 0.25 | 0.35 | 0.05 | 0.03 | 0.03 | - | - | 0.05 | 99.6 |

| 1070 | 0.2 | 0.25 | 0.04 | 0.03 | 0.03 | - | - | 0.04 | 99.7 |

| 1100 | Si+Fe:0.95 | 0.05-0.2 | 0.05 | - | - | 0.1 | - | 99 | |

| 1200 | Si+Fe:1.00 | 0.05 | 0.05 | - | - | 0.1 | 0.05 | 99 | |

| 1235 | Si+Fe:0.65 | 0.05 | 0.05 | 0.05 | - | 0.1 | 0.06 | 99.35 | |

| 3003 | 0.6 | 0.7 | 0.05-0.2 | 1.0-1.5 | - | - | - | 0.1 | remains |

| 3004 | 0.3 | 0.7 | 0.25 | 1.0-1.5 | 0.8-1.3 | - | - | 0.25 | remains |

| 3005 | 0.6 | 0.7 | 0.25 | 1.0-1.5 | 0.20-0.6 | 0.1 | - | 0.25 | remains |

| 3105 | 0.6 | 0.7 | 0.3 | 0.30-0.8 | 0.20-0.8 | 0.2 | - | 0.4 | remains |

| 3A21 | 0.6 | 0.7 | 0.2 | 1.0-1.6 | 0.05 | - | - | 0.1 | remains |

| 5005 | 0.3 | 0.7 | 0.2 | 0.2 | 0.50-1.1 | 0.1 | - | 0.25 | remains |

| 5052 | 0.25 | 0.4 | 0.1 | 0.1 | 2.2-2.8 | 0.15-0.35 | - | 0.1 | remains |

| 5083 | 0.4 | 0.4 | 0.1 | 0.40-1.0 | 4.0-4.9 | 0.05-0.25 | - | 0.25 | remains |

| 5154 | 0.25 | 0.4 | 0.1 | 0.1 | 3.1-3.9 | 0.15-0.35 | - | 0.2 | remains |

| 5182 | 0.2 | 0.35 | 0.15 | 0.20-0.50 | 4.0-5.0 | 0.1 | - | 0.25 | remains |

| 5251 | 0.4 | 0.5 | 0.15 | 0.1-0.5 | 1.7-2.4 | 0.15 | - | 0.15 | remains |

| 5754 | 0.4 | 0.4 | 0.1 | 0.5 | 2.6-3.6 | 0.3 | - | 0.2 | remains |

| 6061 | 0.40-0.8 | 0.7 | 0.15-0.40 | 0.15 | 0.8-1.2 | 0.04-0.35 | - | 0.25 | remains |

| 6063 | 0.20-0.6 | 0.35 | 0.1 | 0.1 | 0.45-0.9 | 0.1 | - | 0.1 | remains |

| 6082 | 0.7-1.3 | 0.5 | 0.1 | 0.40-1.0 | 0.6-1.2 | 0.25 | - | 0.2 | remains |

| 6A02 | 0.50-1.2 | 0.5 | 0.20-0.6 | Or Cr0.15-0.35 | 0.45-0.9 | - | - | 0.2 | remains |

| 8011 | 0.50-0.9 | 0.6-1.0 | 0.1 | 0.2 | 0.05 | 0.05 | - | 0.1 | remains |

- Q: Aluminum metal reacts with hydrochloric acid, HCl, to form hydrogen gas (H2) and a solution of aluminum chloride. Write and balance the equation. Can someone help I just dont get this Al2 + 6HCl → 3H2 + 2AlCl3 Al2 + 2HCl → H2 + 2AlCl 2Al + 6HCl → 3H2 + 2AlCl3 Al + 2HCl → H2 + AlCl2 6Al + 2HCl → H2 + 2Al3Cl

- Aluminum And Hydrochloric Acid

- Q: Describe the various types of coatings applied to steel coils and their applications.

- <p>Steel coils can be coated with several different types of materials to enhance their properties for various applications. Common coatings include: 1) Galvanized coating, which provides corrosion resistance and is used in construction and automotive industries. 2) Pre-painted or color-coated steel, which is coated with organic paint and used for aesthetic purposes in buildings and appliances. 3) Aluminized coating, offering high-temperature resistance and used in heat-treating processes. 4) Zinc-iron alloy coating, which combines the benefits of zinc and iron for enhanced corrosion protection. 5) Organic coatings such as epoxy or polyurethane, used for specific chemical resistance or additional protection in harsh environments. Each type of coating is chosen based on the specific requirements of the end product and the environmental conditions it will face.</p>

- Q: 0.6mm insulation aluminum coil price insulation aluminum coil where to buy the most assured?

- If the surface of the aluminum color, it is directly on the Internet search color coated aluminum roll can be. Best site inspection, and now more factories, quality uneven

- Q: What are the common recycling methods for aluminum coils?

- There are several common recycling methods for aluminum coils. One of the most widely used methods is mechanical recycling, which involves shredding the aluminum coils into small pieces and then melting them down to form new aluminum coils. This method is efficient and cost-effective, as it allows for the reuse of the aluminum material without compromising its quality. Another method is called pyrolysis, which involves heating the aluminum coils at high temperatures in the absence of oxygen. This process breaks down the aluminum into its constituent elements, allowing for the recovery of valuable metals and other byproducts. Chemical recycling is another method that can be used for aluminum coil recycling. This involves dissolving the aluminum coils in a chemical solution to separate the aluminum from other materials. The resulting aluminum can then be used to manufacture new coils. Finally, there is also a method called smelting, which involves melting the aluminum coils and separating impurities through a process called electrolysis. This method allows for the recovery of pure aluminum, which can be used to make new coils. Overall, these recycling methods help to reduce the environmental impact of aluminum coil production by conserving resources and minimizing waste. They also contribute to the sustainability of the aluminum industry by promoting the reuse of materials and reducing the need for virgin aluminum production.

- Q: I planned on making heart shaped pancakes for Valentine's day - is it ok to use aluminum foil as the mold for it? If so, how should I go about it?

- If you are using a frying pan on a gas stove - yes. I fold tin foil into a strongish ribbon then form the shape I want: hearts, gingerbread men, etc. Make sure the pan is fairly warm before you put the tin foil shape in remove the shape as soon as the pancake is set, but before you flip it. You can trim the little splashes before serving. HOWEVER - there are reusable shapes available at many kitchen supply stores. They are not very expensive are permanent additions to your kitchen.

- Q: Are there any specific maintenance requirements for aluminum coils?

- Aluminum coils have specific maintenance requirements that must be met. These coils are commonly used in HVAC systems and need regular cleaning and maintenance to ensure they perform optimally and last a long time. Here are some of the maintenance tasks that should be done for aluminum coils: 1. Keep them clean: It is necessary to clean aluminum coils regularly to prevent the buildup of dirt, dust, and other contaminants. You can use a soft brush or a vacuum cleaner with a brush attachment to do this. Make sure to clean both the fins and the surface of the coils to ensure proper airflow. 2. Inspect them: Regularly inspecting aluminum coils is crucial to identify any signs of damage or corrosion. Look for bent fins, leaks, or any signs of wear and tear. If you notice any issues, address them immediately to prevent further damage. 3. Protect the coils: Applying a protective coating to aluminum coils can help prevent corrosion and extend their lifespan. There are various coatings available specifically designed for aluminum coils that provide an additional layer of protection against environmental factors. 4. Maintain air filters: The air filters in HVAC systems play a vital role in keeping the coils clean. Clean or replace the air filters regularly to prevent dust and debris from accumulating on the coils. Clogged filters can restrict airflow and reduce system efficiency. 5. Follow a maintenance schedule: It is crucial to establish a regular maintenance schedule to ensure all necessary tasks are completed on time. This schedule should include cleaning, inspection, and any other specific requirements recommended by the manufacturer. Consult the manufacturer's guidelines and recommendations for the specific maintenance requirements of your aluminum coils, as they may vary depending on the system and application. By following these maintenance requirements, you can ensure that your aluminum coils function efficiently and have a longer lifespan.

- Q: Almost every restaraunt uses aluminium foils and polyehylene for packing foods - that you carry to home.How safe is this ?For how long would the temperature be mainitained ?and within what time if consumed and is it safe ?

- Aluminium (Al) foil is bad for packaging because some of the Al will be absorbed by the food and too much Al is toxic. Instead of Al cooking vessels you should use stainless steel vessels because some Al will end up in your food from the Al containers or vessels. If you conduct a search for Aluminium (OR Al) poisoning you should learn more. A search for aluminium (OR Al) + toxic dose (OR amount) may also be useful.

- Q: This question asks for the methods and practices to keep aluminum coil in good condition and prevent damage or corrosion.

- <p>To maintain aluminum coil, follow these steps: Store the coil in a dry, clean environment to prevent moisture and dirt from causing rust. Keep it away from corrosive substances. Regularly inspect the coil for any signs of damage or corrosion, and address any issues promptly. Handle the coil carefully to avoid scratches or dents. Use protective coverings during transportation to prevent damage. Keep records of the coil's condition and maintenance history to track its performance over time. Regular maintenance will help extend the life of the aluminum coil and maintain its quality.</p>

- Q: Relevant question 5Excuse me, what's the meaning of your "deoiling effect"? And you answer two kinds of performance, my understanding is that the oil removal effect is not good, lead to aluminum volume is not neat, what is the difference between the two? Solution, thank you

- Oil removal effect is not good rolling oil remover oil extrusion is not complete, coiling in aluminum strip surface residual oil too much, after coiling because of oil coated on the aluminum coil inside played a supporting role in the beginning of aluminum roll edge round, with aluminum coil of diameter increases, the inner pressure increases.

- Q: Are aluminum coils suitable for fire-resistant applications?

- No, aluminum coils are not suitable for fire-resistant applications as aluminum has a low melting point and can easily catch fire or melt in high-temperature environments.

Send your message to us

Painted Aluminum Coils - 1050 1060 3003 3105 5005 5052 8011 for Channel Letter

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 6000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords