Aluminum Coil 5052 PE/PVDF Painted Aluminum Coil 3003 H16

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of PE / PVDF Painted Aluminum Coil 3003 H16

1) Alloy | 1050, 1060,1100, 3003 3004 3105 3A21 5005 5052 etc |

2) Temper | O/H12/H14/H1/H18/H32/H34/H36/H38//H111/H112/H116/H321/T6/T651/T3/T351 etc |

3) Thickness | 0.1mm to 6mm |

4) Width | 20mm to 3300mm |

5) Coil weight | 100kgs to 6 tons depends on actual requirement |

6) Core material | Aluminum or paper |

7) Coil Inner diameter | 75mm, 150mm, 200mm, 300mm, 405mm, 505mm or as required |

8) Protective film can be added

2. Application of PE / PVDF Painted Aluminum Coil 3003 H16

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of PE / PVDF Painted Aluminum Coil 3003 H16

*Such coil is specially designed to replace aluminum ingot, due to the high export tax of aluminum ingot, the coil has better price than ingot.

*This type of coil can fit customer's remelting furnace just like ingot, no need to make any change to the production line that was previously used for ingot. The standard coil size and weight is very suitable for the feed gate of furnace.

*This type of coil causes less material wastage than ingot when remelted.

*Our coil is made directly from ore, no need to go though the ingot making process, quality is much better than other suppliers who use ingot scrap to make coil.

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

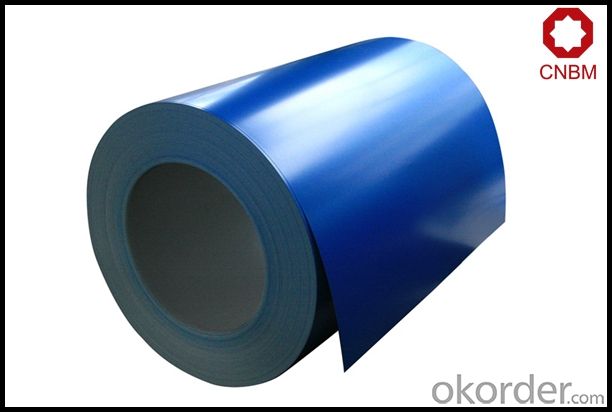

5. Image of PE / PVDF Painted Aluminum Coil 3003 H16

6. Package and shipping of PE / PVDF Painted Aluminum Coil 3003 H16

eye to wall

eye to the wall

with wood pallet (wooded case also available)

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: Can aluminum coils be used for electrical transformers?

- Indeed, electrical transformers can utilize aluminum coils. The application of aluminum as a material for transformer coils is attributed to its superior electrical conductivity and cost-effectiveness in comparison to copper. Traditionally, copper has been favored for transformer windings; nevertheless, the utilization of aluminum has gained traction in recent times due to its lighter weight and more affordable price. Additionally, aluminum coils offer advantages in terms of thermal conductivity, as they efficiently dissipate heat in contrast to copper. Nevertheless, it is crucial to take into account the specific demands and design considerations of the transformer, as the decision between aluminum and copper coils may hinge upon factors such as voltage, current, size, and insulation requirements.

- Q: This question asks for a comparison between steel wires and other materials when used in coilings, highlighting the pros and cons of steel wires.

- <p>The advantages of using steel wires for coilings include high tensile strength, durability, and resistance to corrosion. Steel wires are also cost-effective and widely available. They offer excellent fatigue resistance, making them suitable for applications requiring repeated coiling and uncoiling. Disadvantages include higher weight compared to some alternatives, which can be a concern in certain applications. Steel wires can also be prone to rust if not properly treated, and they may not be as flexible as some other materials, potentially leading to difficulties in handling or installation. Additionally, steel's magnetic properties can be a disadvantage in environments where non-magnetic materials are required.</p>

- Q: The question asks if magnetic induction can be used to inspect the quality of an aluminum coil.

- <p>No, you cannot use magnetic induction to inspect the quality of an aluminum coil. Magnetic induction is a method used to detect flaws or discontinuities in ferromagnetic materials, such as steel, by inducing eddy currents. Aluminum is not a ferromagnetic material, so it does not retain magnetism or support the formation of eddy currents in the same way. Instead, other non-destructive testing methods like ultrasonic testing or radiographic testing may be more appropriate for inspecting the quality of aluminum coils.</p>

- Q: How do aluminum coils compare to other metals in terms of strength?

- Aluminum coils generally have lower strength compared to other metals such as steel or titanium. While aluminum is lightweight and offers good corrosion resistance, it may not possess the same level of strength and durability as some other metals. However, the specific strength of aluminum coils can vary depending on the alloy composition and manufacturing process.

- Q: Are aluminum coils suitable for use in the automotive industry and what are their applications?

- <p>Yes, aluminum coils are widely used in the automotive industry due to their lightweight, high strength, and corrosion resistance. They are utilized in various applications including vehicle body panels, engine components, heat exchangers, and electrical wiring. Aluminum's recyclability and energy efficiency also contribute to its popularity in automotive manufacturing, helping to reduce vehicle weight and improve fuel efficiency while adhering to environmental standards.</p>

- Q: I'm having trouble with another chem problemAluminum sulfide reacts w/water to form aluminum hydroxide and hydrogen sulfide. Write the balanced chemical equation for this reaction and find how many grams of aluminum hydroxide are obtained from 14.2 g of aluminum sulfide.I already found the balanced equation but I need help on finding how many grams of aluminum hydroxide are obtained from 14.2 g of aluminum sulfide. Can someone please explain how it's done?

- No way!! because of the fact inspite of the bat, the helmet and the shin guards the undergo is plenty larger than a human and is going to basically get mad from the bat and kill you. Nope $800,000 isn't something for that!

- Q: What are the common surface preparation methods for aluminum coils?

- To prepare aluminum coils for use, it is necessary to engage in common surface preparation methods such as cleaning, degreasing, and etching. In the surface preparation process, cleaning is typically the initial step. Its purpose is to eliminate any dirt, dust, or other impurities from the surface. Various techniques can be employed for cleaning, including the use of solvents, alkaline cleaners, or mechanical methods like brushing or scrubbing. Degreasing is another crucial aspect of aluminum coil preparation. Its objective is to eliminate any oils or greases that may be present on the surface. Degreasing can be accomplished by employing solvents or alkaline cleaners specifically designed for this purpose. Thorough removal of grease or oils is vital as they can interfere with subsequent treatments and coatings. Etching is commonly performed on aluminum coils to enhance adhesion for subsequent coatings or treatments. It involves creating a roughened surface. Etching can be carried out using chemical etchants or mechanical methods like sandblasting. The choice of etching technique depends on the specific application requirements and desired surface finish. Following surface preparation, additional treatments can be applied to aluminum coils, such as conversion coatings or anodizing, to enhance corrosion resistance or improve surface properties. These treatments safeguard the aluminum surface and provide a foundation for further finishes or coatings. In summary, proper surface preparation plays a critical role in achieving optimal adhesion, corrosion resistance, and overall performance of aluminum coils in diverse applications. It ensures that the surface is clean, free from contaminants, and appropriately prepared for subsequent treatments or coatings.

- Q: Are there any limitations to the widths of aluminum coils?

- Yes, there are limitations to the widths of aluminum coils. The width of aluminum coils is typically determined by various factors such as the manufacturing process, equipment capabilities, and industry standards. One limitation is the maximum width that the manufacturing equipment can handle. Coil processing machines have specific width capacities, which generally range from a few inches to several feet. If an aluminum coil exceeds the maximum width that the machine can accommodate, it may not be possible to process it. Another limitation is related to transportation and handling. Aluminum coils that are too wide may not fit within standard shipping containers or may be difficult to maneuver during transportation. Additionally, wide coils may require specialized handling equipment or additional support, which can increase costs and logistical challenges. Industry standards and application requirements also play a role in determining the limitations of aluminum coil widths. Different industries and applications have specific width requirements for their products. For example, the construction industry may have specific width specifications for roofing or cladding materials, while the automotive industry may have different requirements for body panels. Manufacturers need to consider these standards and customer needs when determining the maximum and minimum widths of aluminum coils. In summary, while aluminum coils can be produced in various widths, there are limitations due to manufacturing equipment capabilities, transportation constraints, and industry standards. These limitations must be considered to ensure the efficient production, handling, and utilization of aluminum coils in different applications.

- Q: Describe the various uses of aluminum coils in the manufacturing industry.

- <p>Aluminum coils are widely used in manufacturing due to their lightweight, corrosion resistance, and strength. They are utilized in the production of various products such as automotive parts, aerospace components, and construction materials. Aluminum coils are also employed in the manufacturing of electrical wiring, heat exchangers, and packaging materials. Additionally, they are used in the production of cans and foils for food and beverage industries. Their versatility makes aluminum coils an essential material in many manufacturing processes.</p>

- Q: What does it mean to slice aluminum coil by decoiler machine?

- The operating procedures of decoiler machine: 1, Select appropriate aluminum coil according to production work order requirement to be processed, paying attention to the thickness, width and material of aluminum coil. 2, Put the aluminum coil into the coil loading car with traveling crane and inch the car into the uncoiler. The aluminum coil and decoiler machine should be in the same direction. Hold the aluminum coil down with leading head, and open the auxiliary bearing. 3, Turn on the shovel head, and inch the uncoiler to lead the aluminum sheet into the leveler. Adjust the leveler according to the thickness and width of aluminum sheet to ensure the flatness. 4, Turn on the front gap bridge and back gap bridge in control main platform, inch the leveler to lead aluminum sheet into re-leveler. Adjust the re-leveler to ensure the flatness of aluminum sheet. Put it into the shear gauge and plate shearer. 5, Take back the front and back gap bridge. Inch the plate shearer to cut off the sheet head and shear the aluminum sheet according to production work order. Check the first sheet to see whether it meets the quality standard and whether there is defect in flatness, length, diagonal, and surface of aluminum sheet. If it is qualified, turn on the conveyor. Put the aluminum sheet holder on the pallet. Adjust the pallet according to the width and length of aluminum sheet. Input quantity and length on the control main platform. Then turn on the auto control to produce automatically. The production process can be observed at any time. 6, If there is aluminum coil left, unwind, package and put it into storage in reverse steps.

Send your message to us

Aluminum Coil 5052 PE/PVDF Painted Aluminum Coil 3003 H16

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords