Aluminum Coil for Channel Letter with Good Price and Excellent Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Structure of Aluminium Coil with Good Price and Excellent Quality Description:

Aluminum coil/sheet are of a wide range of colors, which gives wonderful appearance no matter in residential and commercial constructions of great exhibition centers.

The coated aluminum coil/sheet have been widely used in the fields of construction and decoration( garage doors, ceiling etc.), electronic appliances, lighting decoration, air-condition air pipes, sandwich panels and drainages etc.

Main Features of the Aluminium Coil with Good Price and Excellent Quality:

1) High flexibility

2) Impact resistance

3) Excellent weather-proof durability

4) Anti-ultraviolet

5) High erosion resist

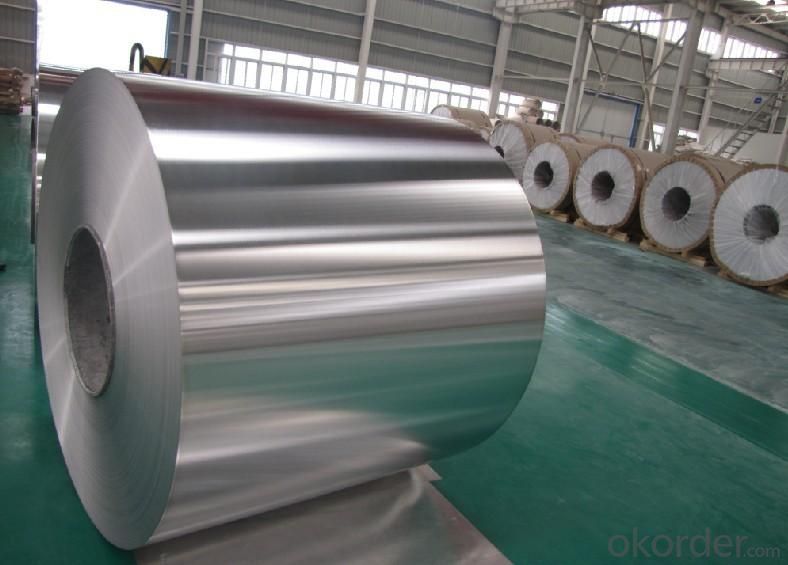

Images of theAluminium Coil with Good Price and Excellent Quality:

Aluminium Coil with Good Price and Excellent Quality Specification:

Alloy | A1100,A3003,A1050,A8011 etc |

Temper | H16,H18,H24 |

Thickness | From 0.024mm to 1.2mm |

Width | Standard width:1240mm |

Special width:1300mm,1520mm,1570mm,1595mm | |

Diameter | Standard dia:1200mm |

Interior dia:150mm,405mm,505mm | |

Weight | 2.5 T/coil,3.0 T/coil |

Coating | PE, PVDF, AC |

Surface | Embossed, mill finish, coated |

Color | AS to code RAL |

Gloss | 10-90%(EN ISO-2813:1994) |

Coating Thickness | PE: more than 18 micron |

PVDF: more than 25 micron | |

Coating Hardness (pencil resistance) | More than 2h |

Coating adhesion | 5J(EN ISO-2409:1994) |

Impact Resistance | No peeling or cracking(50 kg/cm,ASTMD-2794:1993) |

Flexibility (T-bend) | 2T |

MEK resistance | More than 100 |

FAQ:

a.What is monthly capacity

---CNBM is one stated own company and our monthly capacity is about 2000tons.

b. Now which countries do you export your goods?

---Now we export to South East Asia,Africa, North America,South America ect.

- Q: Are there any specific regulations for the disposal of aluminum coil waste?

- Yes, there are specific regulations for the disposal of aluminum coil waste. It is important to adhere to local environmental laws and regulations, which typically require proper handling, storage, and disposal methods for aluminum coil waste. This may include recycling or sending the waste to licensed facilities for proper treatment and disposal. It is recommended to consult with local authorities or waste management agencies for specific guidelines and requirements.

- Q: How do aluminum coils contribute to energy savings in buildings?

- Aluminum coils are an essential component of HVAC (Heating, Ventilation, and Air Conditioning) systems in buildings, and they play a significant role in contributing to energy savings. Firstly, aluminum coils are highly efficient in transferring heat. HVAC systems use these coils to facilitate the exchange of heat between the indoor and outdoor environments. Aluminum's thermal conductivity allows for quick and efficient heat transfer, reducing the energy required to heat or cool a space. This means that HVAC systems equipped with aluminum coils can achieve the desired indoor temperature more efficiently, leading to energy savings. Moreover, aluminum coils are lightweight and have excellent corrosion resistance. This property ensures the longevity and durability of the HVAC system, reducing the need for frequent replacements. By having a longer lifespan, the energy and resources used in manufacturing new coils are saved, resulting in reduced energy consumption and environmental impact. Furthermore, aluminum coils are highly recyclable. When an HVAC system reaches the end of its life cycle, the aluminum coils can be easily recycled and repurposed. Recycling aluminum requires significantly less energy compared to producing new aluminum from raw materials. By promoting recycling, energy is conserved, and greenhouse gas emissions are reduced. Additionally, aluminum's reflective properties contribute to energy savings in buildings. When used in HVAC systems, aluminum coils can reflect and deflect sunlight, reducing the amount of heat absorbed by the building. This reduces the workload on the HVAC system, resulting in lower energy consumption and increased energy efficiency. In summary, aluminum coils contribute to energy savings in buildings through their high thermal conductivity, lightweight and durable nature, recyclability, and reflective properties. By using aluminum coils in HVAC systems, buildings can achieve optimal temperature control with reduced energy consumption, leading to significant energy savings and a more sustainable environment.

- Q: What are the necessary safety measures to take when handling aluminum oxide coated aluminum coils?

- <p>When working with aluminum oxide coating on aluminum coils, it's crucial to follow safety precautions. Always wear appropriate personal protective equipment (PPE), including gloves, safety glasses, and a dust mask to prevent inhalation of dust particles. Ensure proper ventilation to avoid dust accumulation. Handle the material carefully to prevent any skin contact with the coating. Keep the area clean and free from any flammable materials to avoid fire hazards. Be aware of the specific health risks associated with aluminum oxide exposure, and follow the manufacturer's guidelines for safe handling. Regularly inspect equipment for any signs of wear or damage that could lead to accidents.</p>

- Q: This question asks for the most effective methods to clean an aluminum coil, which is a common component in various industries.

- <p>The best ways to clean aluminum coils involve a combination of mechanical and chemical processes. Mechanical cleaning can be done using brushes or pressure washing to remove loose dirt and debris. Chemical cleaning involves using a suitable aluminum cleaner or mild detergent solution to dissolve stubborn grime. Always rinse thoroughly with water to remove any residue. Avoid abrasive materials or harsh chemicals that could scratch the surface. Regular cleaning and maintenance can prevent buildup and extend the coil's lifespan.</p>

- Q: How are aluminum coils used in the production of power transmission lines?

- Due to their unique properties and benefits, aluminum coils are extensively used in the production of power transmission lines. These coils, typically made from high-quality aluminum alloys, offer excellent conductivity, strength, and corrosion resistance. A key application of aluminum coils in power transmission lines is their use in manufacturing overhead conductors. These conductors transmit electrical energy from power plants to substations and distribution networks. Aluminum coils are used to create the conductive core of these overhead conductors because aluminum has lower resistance compared to metals like copper. This low resistance allows for efficient electricity transmission over long distances, minimizing energy loss and improving system performance. In addition, aluminum coils are lighter than copper coils, making them easier to handle and install. This characteristic significantly reduces transportation, installation, and maintenance costs of power transmission lines. Consequently, aluminum coils have become the preferred choice for overhead conductors in power transmission systems worldwide. Moreover, the corrosion resistance of aluminum coils ensures the long-term durability and reliability of power transmission lines. Aluminum naturally develops a protective oxide layer that prevents further corrosion, even in harsh environmental conditions. This corrosion resistance extends the lifespan of transmission lines, reducing the need for frequent repairs or replacements. In conclusion, aluminum coils play a vital role in the production of power transmission lines. They enable efficient electricity transmission, reduce costs, and provide long-lasting corrosion resistance. With these advantages, aluminum coils have become widely adopted in the power industry to enhance the performance and reliability of power transmission systems.

- Q: How are aluminum coils priced in the market?

- Aluminum coils are typically priced in the market based on factors such as the current market demand and supply, the cost of raw materials, production and manufacturing costs, transportation costs, and any additional factors that may affect the overall pricing.

- Q: What are the various applications of aluminum coil in the construction industry?

- <p>Aluminum coil is widely used in construction for various purposes due to its lightweight, durability, and corrosion resistance. It is commonly used in roofing and siding materials for both residential and commercial buildings, providing a long-lasting and low-maintenance option. Aluminum coil is also utilized in the manufacturing of window frames and doors, offering thermal efficiency and strength. Furthermore, it is used in the production of heat exchangers, solar panels, and electrical wiring due to its excellent conductivity. Additionally, aluminum coil is employed in the fabrication of scaffolding and structural components, contributing to the overall stability and safety of construction projects.</p>

- Q: Can aluminum coils be used in high-humidity environments?

- Yes, aluminum coils can be used in high-humidity environments. Aluminum is a corrosion-resistant metal, making it suitable for applications in areas with high humidity levels. The natural oxide layer that forms on the surface of aluminum acts as a protective barrier against moisture and prevents the metal from rusting or corroding. This makes aluminum coils a popular choice for HVAC systems, where they are exposed to moisture and humidity on a regular basis. Additionally, aluminum coils are lightweight, durable, and have excellent heat transfer properties, making them an ideal choice for various industrial and commercial applications in high-humidity environments.

- Q: Is it possible to utilize aluminum coils in the manufacturing of furniture?

- <p>Yes, aluminum coils can be used to make furniture. Aluminum is known for its strength, durability, and resistance to corrosion, making it an ideal material for furniture construction. It is commonly used in outdoor furniture due to its weather resistance. Aluminum coils can be formed into various shapes and sizes to create frames, legs, and other structural components of furniture. Additionally, aluminum's lightweight nature makes it easy to handle and transport, which is beneficial for both manufacturers and consumers.</p>

- Q: I need to make aluminum powder. What machine should I use and what aluminum object should I use?

- I'm not sure I want to answer as its dangerous and can be used to make explosives.

Send your message to us

Aluminum Coil for Channel Letter with Good Price and Excellent Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords