Aluminum Profiles South Africa for Specifications of Auto-Parts Applications

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Structure of Aluminium Profile for Specifications of Auto-parts Applications Description:

Coated aluminum coil/sheet are of a wide range of colors, which gives wonderful appearance no matter in residential and commercial constructions of great exhibition centers.

The coated aluminum coil/sheet have been widely used in the fields of construction and decoration( garage doors, ceiling etc.), electronic appliances, lighting decoration, air-condition air pipes, sandwich panels and drainages etc.

Main Features of the Aluminium Profile for Specifications of Auto-parts Applications:

1) High flexibility

2) Impact resistance

3) Excellent weather-proof durability

4) Anti-ultraviolet

5) High erosion resist

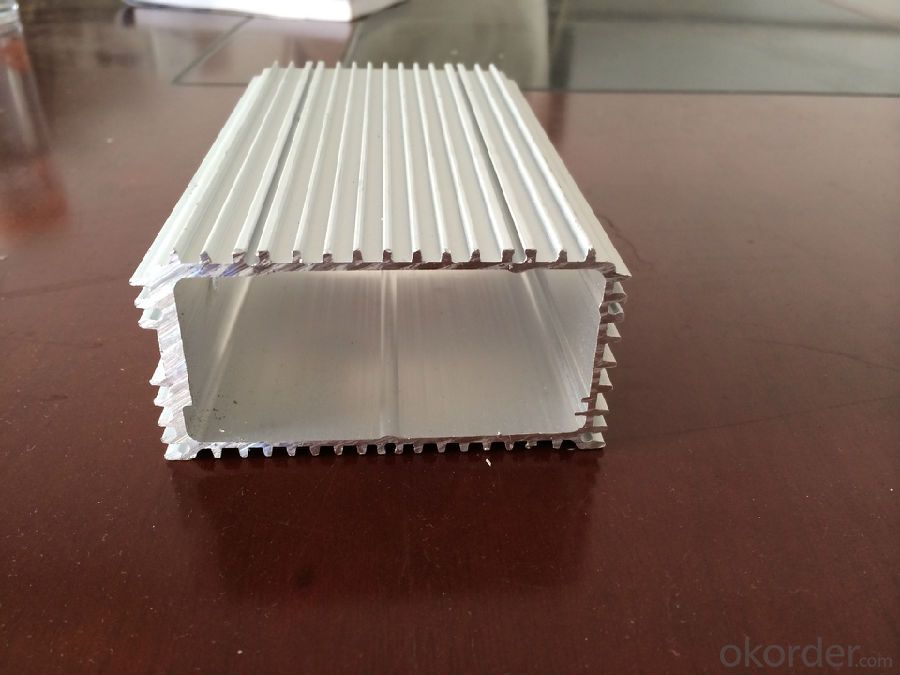

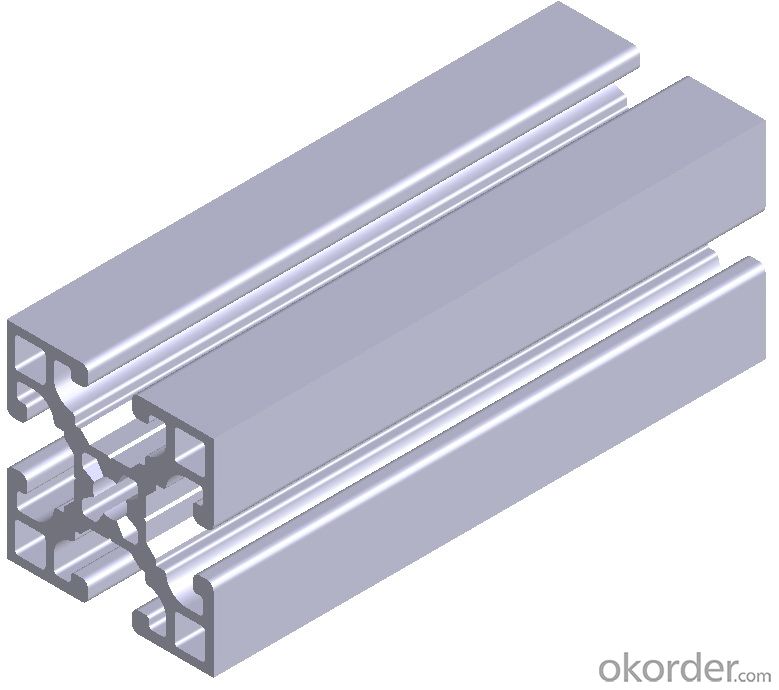

Images of the Aluminium Profile for Specifications of Auto-parts Applications:

Aluminium Profile for Specifications of Auto-parts Applications Specification:

Alloy | A1100,A3003,A1050,A8011 etc |

Temper | H16,H18,H24 |

Thickness | From 0.024mm to 1.2mm |

Width | Standard width:1240mm |

Special width:1300mm,1520mm,1570mm,1595mm | |

Diameter | Standard dia:1200mm |

Interior dia:150mm,405mm,505mm | |

Weight | 2.5 T/coil,3.0 T/coil |

Coating | PE, PVDF, AC |

Surface | Embossed, mill finish, coated |

Color | AS to code RAL |

Gloss | 10-90%(EN ISO-2813:1994) |

Coating Thickness | PE: more than 18 micron |

PVDF: more than 25 micron | |

Coating Hardness (pencil resistance) | More than 2h |

Coating adhesion | 5J(EN ISO-2409:1994) |

Impact Resistance | No peeling or cracking(50 kg/cm,ASTMD-2794:1993) |

Flexibility (T-bend) | 2T |

MEK resistance | More than 100 |

FAQ Aluminium Cast Slab not Alloyed in Coil Form:

a.What is monthly capacity

---CNBM is one stated own company and our monthly capacity is about 2000tons.

b. Now which countries do you export your goods?

---Now we export to South East Asia,Africa, North America,South America ect.

- Q: Can aluminum profiles be used for signage or display purposes?

- Yes, aluminum profiles can definitely be used for signage or display purposes. Aluminum is a versatile and durable material that is commonly used in various industries, including signage and display. Aluminum profiles provide a strong framework for signs and displays, allowing for stability and longevity. The lightweight nature of aluminum makes it easy to handle and install, making it a popular choice for outdoor signage and indoor displays. Additionally, aluminum profiles can be easily customized and fabricated into various shapes and sizes, allowing for creativity and design flexibility. Aluminum profiles also offer excellent resistance to corrosion, ensuring that the signage or display remains in good condition even in outdoor or high-moisture environments. This makes them suitable for a wide range of applications, including storefront signs, directional signs, trade show displays, exhibition booths, and many more. Furthermore, aluminum profiles can be powder coated or anodized to provide a decorative finish, enhancing the visual appeal of the signage or display. This allows for branding and customization options, making the aluminum profiles a great choice for businesses looking to showcase their brand identity. Overall, aluminum profiles are a reliable and versatile choice for signage or display purposes. They offer strength, durability, design flexibility, and resistance to corrosion, making them suitable for a wide range of applications in various industries.

- Q: How do you calculate the weight-bearing capacity of aluminum profiles?

- To calculate the weight-bearing capacity of aluminum profiles, you need to consider various factors such as the dimensions of the profile, the material grade of aluminum used, and the specific application requirements. Firstly, determine the dimensions of the aluminum profile, including the length, width, and thickness. These measurements will help you calculate the cross-sectional area of the profile, which is a crucial parameter in determining its load-bearing capacity. Next, consider the material grade of aluminum used in the profile. Aluminum alloys have different strength properties, so it is essential to know the specific alloy and temper designation. This information can be obtained from the manufacturer or supplier. Once you have the cross-sectional area and material grade, you can refer to engineering standards or handbooks that provide load tables or formulas for calculating the safe load capacity of aluminum profiles. These resources usually provide a range of load ratings based on different loading conditions, such as static or dynamic loads, and factors like span length, support conditions, and safety factors. It is crucial to consider the specific application requirements and any additional factors that may affect the load-bearing capacity, such as temperature, vibration, or potential impact forces. These factors may require further adjustments to the calculated load capacity. Additionally, consulting with a structural engineer or an aluminum profile manufacturer can provide valuable insights and recommendations for calculating the weight-bearing capacity more accurately. They may have specialized knowledge or testing data specific to the aluminum profile in question, ensuring a more reliable calculation. Overall, calculating the weight-bearing capacity of aluminum profiles involves considering the dimensions, material grade, specific application requirements, and consulting relevant resources or experts in the field to ensure accurate and safe load calculations.

- Q: What are the advantages of using aluminum profiles in the aviation industry?

- There are several advantages of using aluminum profiles in the aviation industry. Firstly, aluminum is lightweight, which helps reduce the overall weight of the aircraft, resulting in improved fuel efficiency and lower operating costs. Secondly, aluminum profiles offer excellent strength-to-weight ratio, providing structural integrity and durability to withstand the demanding conditions of aviation. Thirdly, aluminum is corrosion-resistant, making it ideal for withstanding the effects of moisture and other environmental elements. Additionally, aluminum profiles are easy to fabricate, allowing for efficient manufacturing processes and quicker turnaround times.

- Q: How do I maintain and clean aluminum profiles?

- Achieving and upholding the cleanliness and maintenance of aluminum profiles can be accomplished by adhering to the following guidelines: 1. Consistent dusting is key: Commence by employing a gentle cloth or feather duster to eliminate loose dust or dirt. This will hinder the accumulation of grime and simplify the subsequent cleaning process. 2. Create a cleaning solution: Combine warm water with a mild detergent or dish soap in either a bucket or spray bottle. It is important to avoid the usage of harsh chemicals or abrasive cleaners, as they have the potential to cause damage to the aluminum surface. 3. Thoroughly clean the profiles: Immerse a soft cloth or sponge into the cleaning solution and delicately scrub the aluminum profiles. Particular attention should be given to areas that exhibit stains or stubborn dirt. 4. Rinse with fresh water: Subsequent to cleaning, it is crucial to thoroughly rinse the profiles with clean water to eliminate any residual soap or cleaning solution. This step is essential in preventing the formation of streaks or marks caused by dried residue. 5. Dry the profiles: Employ a soft, dry cloth or towel to meticulously wipe the aluminum profiles until they are completely dry. This will help prevent the formation of water spots and preserve the metallic shine. 6. Optional polishing: If desired, a non-abrasive aluminum polish can be applied to further enhance the shine and safeguard the surface. For optimal results, adhere to the instructions provided on the polish packaging. 7. Regular upkeep: In order to maintain the aluminum profiles in excellent condition, it is imperative to engage in regular maintenance practices. This includes consistent dusting, avoiding the usage of abrasive materials or cleaners, and promptly addressing any stains or spills. By adhering to these steps, you can effectively maintain and clean aluminum profiles, thereby ensuring that they retain their pristine appearance for extended periods of time.

- Q: Can aluminum profiles be used in the construction of solar panels?

- Yes, aluminum profiles can be used in the construction of solar panels. Aluminum is a lightweight and durable material that is resistant to corrosion, making it ideal for framing and mounting solar panels. It provides structural support, helps with heat dissipation, and can be easily customized to fit various panel sizes and configurations.

- Q: How do aluminum profiles perform in terms of sound insulation?

- Aluminum profiles typically offer poor sound insulation due to their lightweight and low density. They do not effectively block or absorb sound waves, making them less suitable for applications that require high levels of soundproofing.

- Q: Can aluminum profiles be used in outdoor applications?

- Indeed, outdoor applications can make use of aluminum profiles. Aluminum proves to be a versatile and sturdy substance, exhibiting resistance against corrosion and weathering, thus rendering it apt for outdoor purposes. In the realm of construction, aluminum is frequently employed in the creation of outdoor structures such as fences, railings, pergolas, and outdoor furniture. Furthermore, aluminum profiles can undergo treatments involving diverse coatings or finishes to augment their endurance against UV rays, moisture, and other elements of the environment. In conclusion, aluminum profiles provide a dependable and enduring resolution for outdoor applications.

- Q: Are aluminum profiles resistant to chemicals and acids?

- Yes, aluminum profiles are generally resistant to chemicals and acids due to their natural oxide layer that provides a protective barrier against corrosion. However, certain highly corrosive chemicals or acids may still cause damage over time.

- Q: Are aluminum profiles suitable for outdoor sign applications?

- <p>Yes, aluminum profiles are commonly used for outdoor signage due to their durability, resistance to corrosion, and lightweight properties. They can withstand various weather conditions without rusting or fading, making them an ideal material for long-lasting outdoor signs. Aluminum profiles can be easily cut, shaped, and assembled, offering flexibility in design and functionality.</p>

- Q: This question asks for a comparison of the benefits and drawbacks of utilizing aluminum profiles in the construction of buildings.

- <p>Aluminum profiles in building construction offer several advantages such as high strength-to-weight ratio, corrosion resistance, and ease of fabrication. They are lightweight, which reduces the load on structures, and they are recyclable, contributing to sustainability. Additionally, aluminum profiles can be easily shaped and joined, making them versatile for various architectural designs. However, they also have disadvantages. Aluminum is a good conductor of heat, which can lead to thermal bridging and energy inefficiency if not properly insulated. It can also be more expensive than some traditional materials like steel or wood. Moreover, aluminum's light color can cause glare issues, and it may require additional protective coatings to prevent weathering and maintain its appearance over time.</p>

Send your message to us

Aluminum Profiles South Africa for Specifications of Auto-Parts Applications

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords