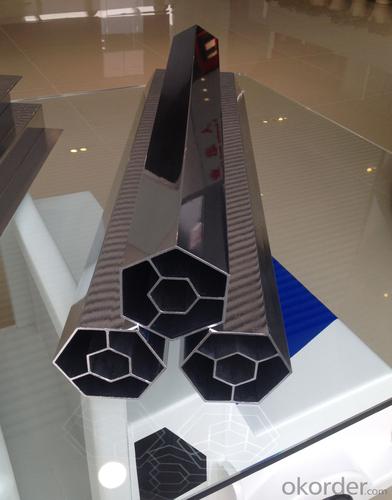

Aluminum Pipes for Vehicle Structure Aluminum Profile

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

We are the largest aluminum profilemanufacture in

Material | Alloy Aluminum 6063,6061,6005,6082 or customer nominated |

Temper | T3, T4, T5, T6 and other |

Surface | Anodize, electrophoresis, Mill,etc |

Colour | -- |

Length | Not more than 16 meters |

Good Package | Inner plastic film /outside carton/wooden pallets |

Payment Method | T/T, L/C, etc |

Delivery Time | Normally 2-4 weeks, Delivery time can be consulted. |

Press Machine | 500-12500 tons all together 93 press lines. |

Fabrication | 1. Car body; 2. Drilling; 3. Bending; 4. Cutting; 5. etc. |

Certificate | ISO/TS 16949,DNV,IRIS,CCS,AFA,etc. |

Dies | 1. Using our dies, no fee; |

2. Using customer drawing, opening dies, usually about 5~50 tons then the dies cost can be refunded. | |

3. Die cost is negotiable base on the order quantity | |

Capability | Annual output 800,000 tons |

- Q: Hello, there's a question I'd like to ask. 'I'd like an aluminum pipe bender', but it won't do '

- Landlord: actually, this is very simple to solve, you just need to find the root of thin wire, according to the drawings by hand bend again, then according to your bending appearance, can according to your order of elbow bending on pipe bender, as long as you do a few times, clear topspin, backspin!

- Q: 6063, how to prevent cracking aluminum tube, variant manual bending machine bending machine bending, what should pay attention to?No one knows?

- 6063, aluminum tube plasticity is very good, if you want to bend, it is recommended to return the fire, reduce the hardness, bending after quenching, bend pipe bend can be.

- Q: 1100 what is the difference between the aluminum tube and the 6063 material aluminum tube, please advise

- The 1100 is rust proof aluminum grades, good corrosion resistance, good plasticity, but the intensity is the lowest, 6063 forging Aluminum Alloy, is Aluminum Alloy, if after solid solution treatment and aging, high strength and hardness, but the corrosion resistance of less than 1100,

- Q: How do aluminum pipes compare to titanium pipes in terms of weight?

- Aluminum pipes are generally lighter in weight compared to titanium pipes.

- Q: Are aluminum pipes suitable for oil refineries?

- Yes, aluminum pipes are generally not suitable for oil refineries due to their lower corrosion resistance compared to other metals like carbon steel or stainless steel.

- Q: What is the difference between the aluminum tube connection and the copper tube connection of the air conditioner?

- The air conditioning copper tube is a kind of pressed and drawn seamless pipe. The air conditioner copper tube has the advantages of light weight, good heat conductivity and low temperature intensity. Copper tubes are often used as connecting pipes for air conditioners. Air conditioning aluminum tube is also a kind of non-ferrous metal pipe. The air conditioning aluminum tube is made of pure aluminium or aluminum alloy and is extruded into a hollow metal tube with longitudinal length. Air conditioning aluminum tube has "annealing, quenching and hot state, medium plasticity, good weldability, weldability" and so on. Aluminium tubes are also used for air conditioning. But for the moment, copper tubes are more suitable for air conditioning than aluminum tubes.The difference between air conditioning copper tube and aluminum tube:1 、 the material of copper tube and aluminum pipe is different.2, the copper pipe and aluminum pipe flow is different.3, copper and aluminum prices are different: Copper costs high.4, the application of copper and aluminum, brass, good ductility, resistance to oxidation, bellbottom do good pressure resistance, not easy leakage of refrigerant, are often used in air conditioning; aluminum can do bell, pressure difference of oxidation resistance, it is prone to leak, if not good insulation cotton, it is a hidden danger.5, copper and aluminum bending: aluminum tube bending, better than copper bending resistance.

- Q: Do aluminum pipes require insulation?

- Yes, aluminum pipes can benefit from insulation. Insulating aluminum pipes helps to prevent heat loss or gain, depending on the application. It helps to maintain the temperature of the fluid or gas inside the pipe, which can be especially important in HVAC systems, industrial processes, or hot water distribution systems. Insulation also reduces the risk of condensation forming on the pipe's surface, which can lead to corrosion or damage over time. Additionally, insulation can help to reduce energy costs by minimizing heat transfer and improving overall system efficiency. Therefore, while it is not always necessary, insulating aluminum pipes is highly recommended in many applications.

- Q: Does GREE have aluminium tubes?

- There should be none. All the air conditioners are copper tubes

- Q: Can aluminum pipes be used for irrigation controllers?

- Yes, aluminum pipes can be used for irrigation controllers. Aluminum pipes are commonly used in irrigation systems due to their durability, corrosion resistance, and lightweight nature. They are also cost-effective and relatively easy to install and maintain. However, it is important to consider the specific requirements of the irrigation system and consult with professionals to ensure the suitability of aluminum pipes for the specific application.

- Q: Are aluminum pipes suitable for vacuum systems?

- Yes, aluminum pipes are suitable for vacuum systems. Aluminum is a commonly used material in vacuum systems due to its excellent strength-to-weight ratio, corrosion resistance, and ability to maintain a vacuum-tight seal. Additionally, aluminum pipes can be easily welded, allowing for seamless connections and minimizing the risk of leaks in vacuum applications.

Send your message to us

Aluminum Pipes for Vehicle Structure Aluminum Profile

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords