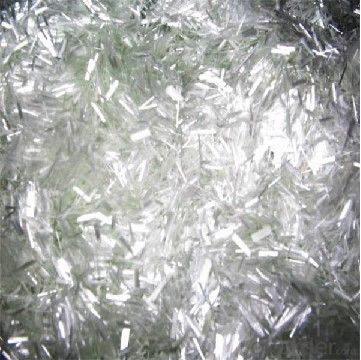

Alkali Resistant GRC Chopped strands for wall plastering materials

- Loading Port:

- Shanghai Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 15.6MTS

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of Alkali Resistant GRC Chopped strands for wall plastering materials:

1) length:3.0mm,4.5mm,6.0mm,9.0mm,12mm,15mm

2) Good strand integrity

3) Low static

4) Good flowability

Features of Alkali Resistant GRC Chopped strands for wall plastering materials:

--Good strand integrity, low static and good flowability;

--Fast and uniform distribution in resins, good processing properties and good mechanical properties of the end products;

--Good bonding with resins. No fiber sticking out at the surface of the end products and aesthetic appearance.

Application of Alkali Resistant GRC Chopped strands for wall plastering materials:

It is mainly used in injection and compression molding processes and its typical end-use applications include automotive industry, home appliances, valves, pump housings, chemical corrosion resistance and sports apparatus.

Packaging of Alkali Resistant GRC Chopped strands for wall plastering materials:

The product can be packed in bulk bags, cardboard boxes or composite plastic woven bags;

Bulk bags can hold 500kg~1000kg each;

Cardboard boxes and composite plastic woven bags can hold 15kg~25kg each.

Storage of Alkali Resistant GRC Chopped strands for wall plastering materials:

Unless otherwise specified, fiberglass products should be stored in a dry, cool and rain-proof area. It is recommended that the room temperature and humidity should be always maintained at 15-35,35%-65% respectively.

- Q: why cement board over hardie backer board when laying down a counter top for kitchen sink?

- Wood tick is right, cement board over a minimum 3/4 plywood on counters. If you mean choosing cement board over hardy backer board, I choose cement board any day. Durock in particular. I ve used it and never had problems in 20+ years that I ve been setting tile. Any questions you can e mail me through my avatar and check my qualifications there. GL

- Q: does anyone have any experience in that? does it reduce the noise a lot or just a bit? and about the ceiling... my neighbors throw and drag things on the floor (they're mental cases, fruitcakes). i can't afford to move right now because the house is bought so i'd have to sell and buy another house. can't do that right now. and it always costs money.to what extent will the cement on the ceiling reduce the noise?what kind of windows are the best?thank you all...

- I have a best reply for you...I am an excessively mild sleeper, and so they truthfully make instruments that make white Noise. They almost make a whirring sound, very similar to a fan, however the frequency is such that it particularly is helping to dam out external noises as good as sporadic noises, such because the mobilephone ringing or sounds from persons speakme. They additionally promote sound machines that make a style of sounds starting from rain, to babbeling brook to the sound of night time time crickets. To discover the white noise machines simply sort that into the seek bar, many web sites promote them at fair charges. Hope this is helping you out!

- Q: I never used to be allergic to anything and then a few years ago developed an allergy to shell fish. Yesterday I was working with rubber cement for the first time and I had a major allergic reaction similar to the ones I would have after eating shrimp. Is there anything in rubber cement that would relate to shellfish? There is nothing printed on the label but it does warn of allergic reactions if you are allergic to latex gloves. Not sure if I am or not but maybe.....given this experience.

- Rubber cement is an adhesive made from elastic polymers (typically latex) mixed in a solvent such as acetone, hexane, heptane or benzene to keep them fluid enough to be used. This makes it part of the class of drying adhesives: as the solvents quickly evaporate, the rubber portion remains behind, forming a strong yet flexible bond. Often a small percentage of alcohol is added to the mix.

- Q: I have 300sq feet of yard space that's infested with worms and all sorts of creeters. I wanna cover 100 ft of. This yard in cement. And grow nice healthy grass behind it. Hope yall can help me out

- First off, its concrete, not cement. Cement is only an ingredient in concrete. Second of all, whats wrong with worms and critters. Yikes, without them we wouldn't have food, our eco system would collapse, and we would all die. Third of all, weeds can be used as nicely as lawns, achieving that perfect piece of lawn is ugly and harsh on our enviroment. Of course you can concrete a section of your yard, you level and grade it and then have it poured. To achieve you perfect lawn apply toxic herbicides and pesticides, continue to pollute our soils and waterways further, kill off beneficial insects such as bees and bugs, let those poisions run off into our water ways, kill our fish, and contribute to the demise of the eco system just a little bit further. Then go ahead and plant some grass seed that doesn't even thrive in you climate, then you will need to pump tons of water and fertilizer into monthly to achieve that perfect look. Then sit back and enjoy your little piece of toxic heaven. Now enjoy it a lot, because you will be enjoying for you great grand children as well, because they won't have a planet to live on. A conciseness person would think to themselves, why not just clean it up by hand and plant a garden, feed you family, feed a friend, feed the neighbor hood, and take care of your own just a little bit and conquer your complete dependence on the grocery store.

- Q: history of the development of cement?

- a combination of hydrated non-hydraulic lime and a pozzolan produces a hydraulic mixture (see also: Pozzolanic reaction), but concrete made from such mixtures was first used by the Ancient Macedonians[1][2] and three centuries later on a large scale by Roman engineers.[3] They used both natural pozzolans (trass or pumice) and artificial pozzolans (ground brick or pottery) in these concretes. Many excellent examples of structures made from these concretes are still standing, notably the huge monolithic dome of the Pantheon in Rome and the massive Baths of Caracalla.[4] The vast system of Roman aqueducts also made extensive use of hydraulic cement.[5] Although any preservation of this knowledge in literary sources from the Middle Ages is unknown, medieval masons and some military engineers maintained an active tradition of using hydraulic cement in structures such as canals, fortresses, harbors, and shipbuilding facilities.[6][7] The technical knowledge of making hydraulic cement was later formalized by French and British engineers in the 18th century.[6]

- Q: Will the building materials cement 425 and 325 labels have any difference in the quality of the impact of life, please tell me please?

- 425 mark 28 days Compression greater than or equal to 42.5 MPa; 325 mark 28 days Compression greater than or equal to 32.5 MPa

- Q: I have cement stair and the rod iron railings have rusted off. There is only one post left. Can this be taken off and new one added without replacing the steps? What kind of store would have the railings and how would you go about finding someone to install them?

- Here you go, one at a time. Yes, railings built of all types of materials (iron, wood, pvc, etc) can be added to existing cement steps. Yes, a small grinder will get rid of the existing post. There are several fasteners designed to attached materials to concrete. If you are attempting to do this yourself, I prefer lag bolts and shields, because they are the sturdiest and most forgiving. Any hardware store will have them and can set you up. Any big home improvement store will have both wood and pvc materials that will allow you to build the steps yourself if you are so inclined. Any decent carpenter will be able to handle this for you if you would like. If you want iron railings, they do have those at some of the bigger stores. They allow you to cut pieces and connect them to build your railing. These are cheap and will not last long. If you really want iron, find a fabricator (iron works) shop locally and have them give a price on building and if you would like installing your new rail. Depending on how many steps you have, iron will probably cost at least three to four times as much as wood or pvc.

- Q: what is the difference between cement and concrete ?

- Cement is one of the ingredients used to make concrete. In other words concrete is the final product of which cement is used with other ingredients to make it. The mixup in terms is widespread. The DIY tv shows always misuse the terms such as this. They call concrete Blocks - Cinder blocks and Cement Blocks. The architectural term of *CMU means Concrete Masonry Unit. The also say Masonary - it's not Masonary it is Masonry - no *A after the n. The term Cement Finisher is correct in construction terms - however they are actually finishing concrete. Cement is an ingredient of Mortar also as well and of Thinset mortar for ceramic tile. So cement is an ingredient of a lot of products. The most prominent one is Concrete.

- Q: It doesn't have 2 b painted it just has 2 b cement and in Ohio

- use the phone and try various places-----garden shops, statue places and landscaping businesses which may advise you.

- Q: I recently had my braces removed and while looking in the mirror at my teeth, I noticed black discoloration on several teeth. Is this a common color of the adhesive they use or did my teeth somehow get massive cavities?

- Orthodontic cement is clear hen they out it on and sort of whitish when it dries. So I have no idea what's on your teeth.

1. Manufacturer Overview

| Location | Hubei,China |

| Year Established | 2005 |

| Annual Output Value | US$50 Million - US$100 Million |

| Main Markets | Southern Europe 10% Northern Europe 10% Central America 10% Western Europe 10% Eastern Asia 10% Mid East 30% Africa 20% |

| Company Certifications | N/A |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai PORT |

| Export Percentage | |

| No.of Employees in Trade Department | 6-10 People |

| Language Spoken: | English;Chinese; |

| b) Factory Information | |

| Factory Size: | Above 100,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | |

| Product Price Range | 示范:High;Average |

Send your message to us

Alkali Resistant GRC Chopped strands for wall plastering materials

- Loading Port:

- Shanghai Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 15.6MTS

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords