Alkali Resistant Glassfiber Chopped Strand

- Loading Port:

- Shanghai Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 15.6MTS

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

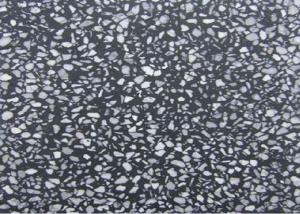

Specifications of Alkali Resistant Glassfiber Chopped Strand:

1. AR Chopped Strand for GRC,GRG

2. Good mechanical properties

3. Low static,good flowability

4. Good bonding with resin

Description of Alkali Resistant Glassfiber Chopped Strand:

ARG chopped strand is designed to use in dry mix systems or other premixing processes GRC(Glassiber reinforced concret).Such as drainage channels, cable troughs, meter boxes, wall cladding panels or in architectural applications such as decorative screen walling, etc.

ARC15-98-(3-30)mm ZrO2 14.5%

ARC13-76-(3-30)mm ZrO2 16.5%

Properties of Alkali Resistant Glassfiber Chopped Strand:

Good liquidity and high integrity, Excellent alkali resistant and durability

Package of Alkali Resistant Glassfiber Chopped Strand:

20kgs/kraft bag, 50 bags/pallet, 20 pallets/20'FCL(on 2 levels), total net weight for 18 tons.

Storage of Alkali Resistant Glassfiber Chopped Strand:

AR fiberglass chopped strand should be stored dry in their original package, the best conditions being at a temperature of between 15 and 35, and at a relative humidity of between 35 and 65%. If the product is stored at low temperature (below 15), it is advisable to condition in the workshop for 24 hours before use to prevent condensation.

- Q: teeth which was used to apply the braces. Can i get a cleaning a regular dentist remove the cement ot return to a orthodontist. I removed the braces cause I was young and moved far away from home. Boy do i regret that just because of this mess I have on my teeth.

- If you call a regular dentist's office to make an appointment, tell them about the cement. There are specific tools used to remove the orthodontic cement from the teeth, and not all offices have them. Some general dentists also do orthodontics, so they might have the tools, but they would still need to allow extra time because removing a significant amount of cement takes more time than a standard cleaning would. If you haven't been back to a dentist since you were young, it would also be best to see a general dentist (who also does orthodontics) because they will be able to check for decay and periodontal disease at the same appointment where they remove the cement.

- Q: how does sediment compact or cement into sedimentary rocks?

- Lithostatic load! As sediment is deposited into basins, the pressure from the weight of the overlying sediment presses and squeezes the seds into hard, rocky bodies. Water plays a part of this as well. Water can allow for the precipitation of cement in sandstone (Calcium Carbonate).

- Q: testing cement resistor by mulitmeteror digital tester

- Never heard of a cement resistor. Could be CERMET? But to test a resistor, connect the leads of the multimeter across it, (it has to be disconnected from any other circuit components) set the multimeter to the ohms mode. .

- Q: On the gas tank of my motorcycles is edged rubber and edged thin steel. The edged rubber slides into the edge of the steel. Some of the rubber has come off the edge of the steel, and I was wondering how could I glue it. I thought of rubber cement, but I don't know. Also should I prime the steel by taking some light sandpaper to it? Thanks.

- use some good super glue.. it makes a stronger bond. and the excess can be sanded off after it dries, its better to over apply than to under apply.

- Q: I want to do a flooring of my new house by Cement:Sand (1:3)ratio and would like to know the quantity of cement needed per square meter for plastering. The floor thickness will be 2~3mm.

- Simple LxWxH Length times width x height

- Q: For a science projekt i need to use a material that is stronger than plaster but not to heavy like cement or if u know a brand of plaster that is really strong or vice versa with cement please tell me. it would be great If the cost is less than 50 dollars for 10kg than

- There is a product that is just called lightweight cement. It is used in fabrication of heavy duct work for extreme heat conditions such as power plants and such. You can also buy this product at most hardware or lumber yards. If you need to have it stronger, you can either add more portland to the mix or add stainless needles. The needles (or other types of additives) help to resist wear and give better strength to the cement with out adding much weight.

- Q: how many bags of portland cement do I need to build a slap of 40m by 30 m by 10cm?

- Contact Portland Cement, their reps will be able do the calculations for you. They will need to know which Portland cement product you are using.

- Q: why is cement still very high when everything is going down?

- Because the cement cartel is a member of the Phil governing bodies .

- Q: is it possible to make my pvc cement quot;normalquot; again... because now its all dry...

- You would be better off to buy some new stuff, but there is a remote possibility you can make it glue again by mixing some acetone in to it, but, but , but the acetone is more expensive than buying new pvc cement. So the moral of this story is; buy new pvc cement and get used to the idea that the stuff will dry out with some regularity. Actually eventually it all dries out even if you are careful to close the can very tight. It is a universal truth in life. I wish I had $5.00 for every can of that stuff that has gotten hard on me.

- Q: what is the man made cement made from ?

- My body makes cement all the time.

1. Manufacturer Overview

| Location | Hubei,China |

| Year Established | 2005 |

| Annual Output Value | US$50 Million - US$100 Million |

| Main Markets | Southern Europe 10% Northern Europe 10% Central America 10% Western Europe 10% Eastern Asia 10% Mid East 30% Africa 20% |

| Company Certifications | N/A |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai PORT |

| Export Percentage | |

| No.of Employees in Trade Department | 6-10 People |

| Language Spoken: | English;Chinese; |

| b) Factory Information | |

| Factory Size: | Above 100,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | |

| Product Price Range | 示范:High;Average |

Send your message to us

Alkali Resistant Glassfiber Chopped Strand

- Loading Port:

- Shanghai Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 15.6MTS

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords