Crystalline Silicon Wafer Solar Cells - A Grade Polycrystalline Solar Cell 4.2W-4.3W

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 watt

- Supply Capability:

- 10000 watt/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

A Grade Polycrystalline Solar Cell 4.2W-4.3W

Main Characteristic

17.6%-18% High Efficiency A Grade 125mm Monocrystalline Solar Cells

1.First-class production technology and packaging technology.

2.Adopting the world's leading technology of silicon and polycrystalline silicon cells, power density, peak hours more battery power, higher conversion efficiency.

3.Beautiful, stable, easy to take down the anodic aluminum frame electric degrees and has a wind-resistant, anti-snow function.

Features

17.6%-18% High Efficiency A Grade 125mm Monocrystalline Solar Cells

1.High transmissivity low-iron tempered glass, strong aluminium frame.

2.Manufactured according to international quality and Environment Management System (ISO9001, ISO14001).

3.Low voltage-temperature coefficient allows higher power output at high-temperature condition.

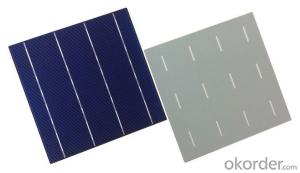

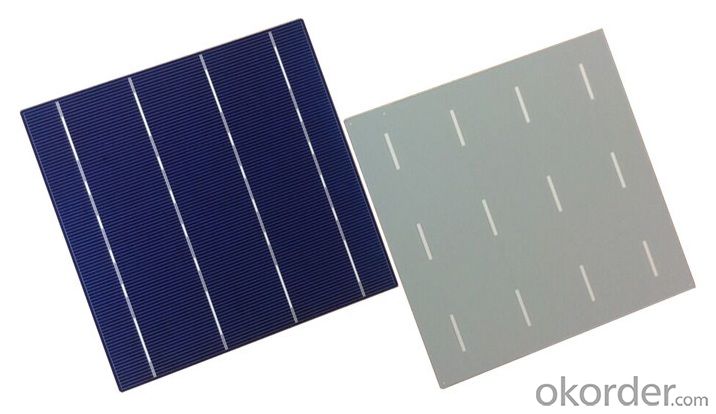

Product Pictures

Top 7 Reasons to Order From Us:

1) We offer you the best quality on the market!

2) We offer you strongly competitive prices !

3) We offer the fastest shipping !

4) we can accept small order!

5) we design various of watt according to cuatomer!

6) We have the best customer service team!

7) We have excellent manufacturer solar panel warranty policy!

- Q: What is the impact of temperature on the performance of solar silicon wafers?

- The impact of temperature on the performance of solar silicon wafers is significant. Higher temperatures generally lead to a decrease in the efficiency of solar cells, resulting in reduced power output. This is primarily due to the increased resistance within the silicon material, which leads to a higher voltage drop and lower current flow. Additionally, higher temperatures can cause an increase in the rate of electron-hole recombination, further reducing the efficiency of the solar cell. Therefore, it is crucial to manage and control the temperature to optimize the performance of solar silicon wafers and maximize their energy conversion capabilities.

- Q: I am not learning electricity, the problem is not professional please understandFor example, in the past, we are in the physics of the secondary wire or wire that is connected to the resistance in the integrated circuit is how to reflect? I know it is the use of lithography technology, is not equivalent to the formation of a line into a line (corrosion into the groove)? And then connect the resistors and capacitors

- Integrated circuit (integrated circuit) is a kind of micro electronic device or component. With certain techniques, the transistor, required a circuit of resistance, capacitance and inductance components and interconnect wiring together, produced in a small or a few bits of the semiconductor wafer or substrate, and then encapsulated in a tube shell, a micro structure required for the circuit function; all of them element in the structure has formed a whole, so that the electronic components to miniaturization, low power consumption, high reliability and intelligent a huge step forward. It is represented by the letter "IC" in the circuit. The inventor of the integrated circuit is Jack Kilby (based on Ge) and the (silicon based (Si) integrated circuit). Most of the semiconductor industry today is based on silicon integrated circuit.A new type of semiconductor device developed in the late 1950s of 60s. It is through oxidation, photolithography, epitaxy, diffusion, evaporation of aluminum and semiconductor manufacturing process, the connecting wire between the required circuit has a certain function of the semiconductor, resistors, capacitors and other components and they are integrated in a small piece of silicon wafer, and then welding electronic devices are encapsulated in a casing. The outer shell of the utility model is provided with a round shell type, a flat type or a double line type. IC technology includes chip manufacturing technology and design technology, mainly in the processing equipment, processing technology, packaging testing, mass production and design innovation ability.

- Q: What are the different manufacturing processes for solar silicon wafers?

- There are primarily two manufacturing processes for solar silicon wafers: the Czochralski (CZ) process and the Float-zone (FZ) process. In the CZ process, a silicon seed crystal is dipped into a molten silicon melt, and as it is slowly pulled out, a single crystal ingot is formed. This ingot is then sliced into thin wafers. On the other hand, the FZ process involves melting a silicon rod from one end and slowly solidifying it in a controlled manner. This results in a single crystal silicon rod that can be sliced into wafers. Both processes produce high-quality silicon wafers, but the CZ process is more commonly used due to its higher productivity and lower cost.

- Q: Why not use crystal silicon battery N type silicon, boron diffusion is difficult, or material difficult to do, or the principle of the problem?

- N type silicon wafer from the raw material price or quantity, and P type silicon wafer or some gap. This also led to the battery chip manufacturers for N battery has been in the laboratory stage, not mass production.Again, the P type battery is to take GA or boron, but the N type batteries into another material, I am not very clear, not engage in technology, huh, huh, huh, huh.The above information, I hope to help you.

- Q: How is an encapsulant applied to a solar silicon wafer?

- An encapsulant is typically applied to a solar silicon wafer through a process called lamination. This involves placing the wafer between two layers of encapsulant material, such as EVA (ethylene-vinyl acetate), and then subjecting it to heat and pressure. The heat melts the encapsulant, enabling it to bond with the wafer, while the pressure ensures uniform distribution of the material and helps to remove any air bubbles. This lamination process provides protection to the solar silicon wafer from environmental factors and enhances its durability and performance.

- Q: Can solar silicon wafers be used in urban environments for power generation?

- Yes, solar silicon wafers can be used in urban environments for power generation. They are commonly used in photovoltaic systems to convert sunlight into electricity. With proper installation on rooftops, balconies, or other available spaces, solar silicon wafers can effectively harness solar energy and contribute to power generation in urban areas.

- Q: Can solar silicon wafers be used in smart grid systems?

- Yes, solar silicon wafers can be used in smart grid systems. Solar silicon wafers are the key component of solar cells used in photovoltaic systems, which can generate electricity from sunlight. Smart grid systems aim to enhance the efficiency, reliability, and sustainability of electricity distribution and consumption. By integrating solar silicon wafers into smart grid systems, solar energy can be harnessed and integrated into the grid, contributing to renewable energy generation and promoting a cleaner and more sustainable power supply.

- Q: Can solar silicon wafers be used in aerospace applications?

- Yes, solar silicon wafers can be used in aerospace applications. Solar panels made from silicon wafers are commonly used in satellites and other spacecraft to generate electrical power from sunlight. They are lightweight, durable, and efficient, making them ideal for aerospace applications where power generation is crucial.

- Q: Silicon wafer is not light mixed with heavy doping?That is not mixed with P type N type, then ask what is the meaning of SUBThere are light doped tablets with heavy doping in the semiconductor industry is how to express?

- Whether it is N or P type, doping, resistivity is low, that is RE doped

- Q: How do solar silicon wafers perform in low-light conditions?

- Solar silicon wafers perform relatively well in low-light conditions due to their ability to capture and convert even small amounts of sunlight into usable energy. However, their efficiency decreases as the light intensity decreases, resulting in a lower energy output compared to bright sunlight conditions.

Send your message to us

Crystalline Silicon Wafer Solar Cells - A Grade Polycrystalline Solar Cell 4.2W-4.3W

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 watt

- Supply Capability:

- 10000 watt/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords