1050 Series/750 Series Adjustable Steel Frame Formwork

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

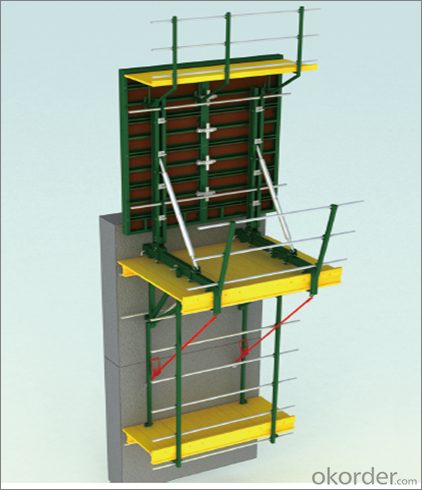

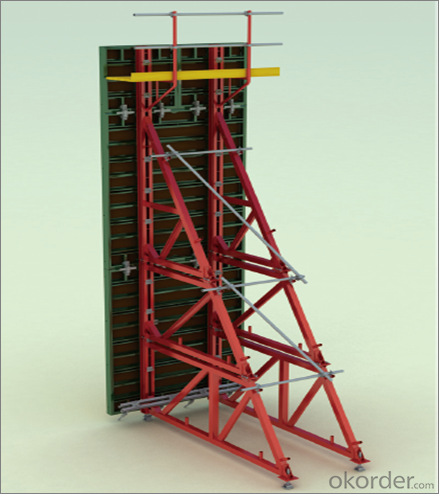

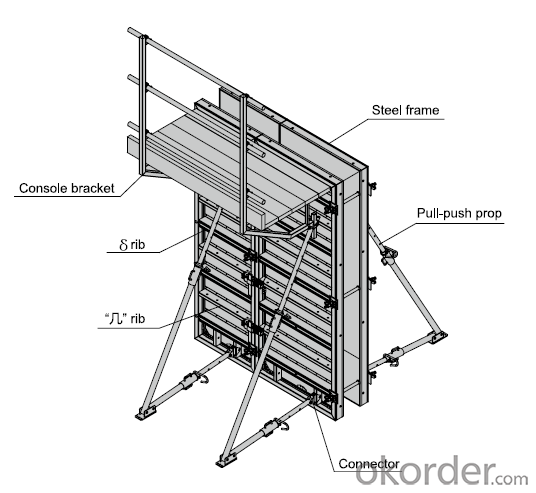

1. Structure of Steel Frame Formwork

There is a prizing part designed in the corner, which can help to position and remove formwork easily.

The plywood is screwed on from the back when connecting frame and plywood, so the surface of the finished concrete is perfect.

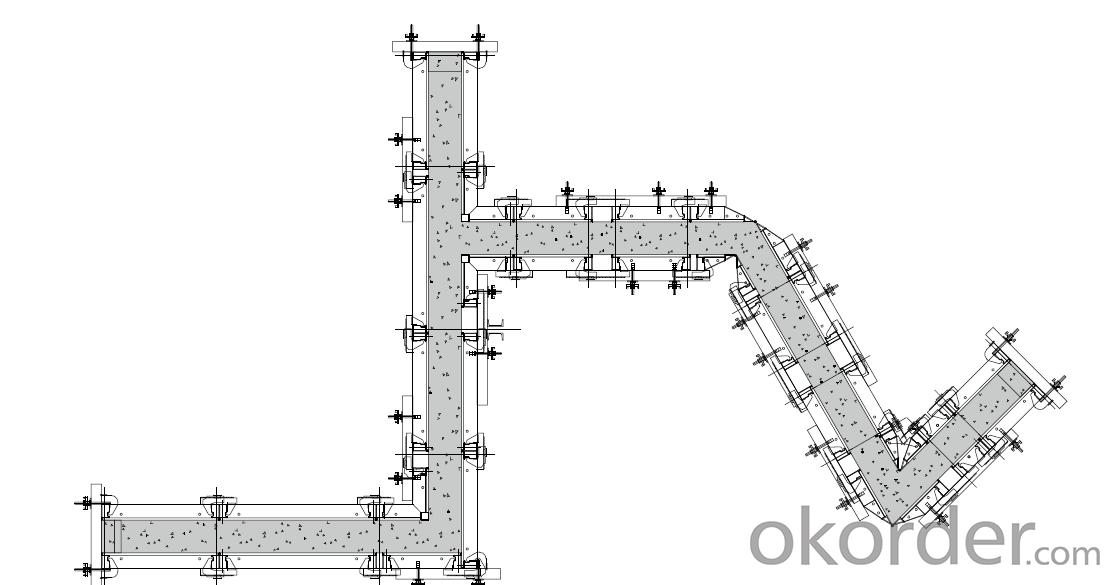

The formwork series are a complete system with a full set of accessories, and can be set up flexibly according to project demand.

2. Main Features of Steel Frame Formwork

Light weight

High strength

High standardized system

Easy connection with adjustable steel clamp

Convenient and fast corner formwork

Flexible to assemble and application

3. Steel Frame Formwork Images

4. Steel Frame Formwork Specification

-The steel frame formwork is plywood covered with hollow steel. The plywood is 18 mm thick.

-The frame is highly strengthened, and the wall formwork can bear lateral pressure 60 KN/m2 while the column formwork can bear 80 KN/m2.

-As a standardized system, it is flexible to assemble , wood batten can be filled to satisfy the need f of non-standard size.

-The adjustable steel clamp is convenient to use, and can hold tightly.

5. FAQ of Steel Frame Formwork

1) What can we do for you?

.We can ensure the quality of the vinyl banner and avoid extra expenses for customers.

.We can provide you the professional design team.

.We can provide fashionable and newest styles for you.

.We can design the artwork for you.

. Please feel free to customize.

2) What promises can be done by us?

. If interested in Steel Frame Formwork , please feel free to write us for any QUOTE.

. If printing required, please advise asap because the whole set need much more time to complete.

. Please DO check goods when courier knocks your door and contact us asap if any issue.

3) What about of our after-sale service?

. Response will be carried out in 24hours after receiving any complain or request.

. Steel Frame Formwork GK120 cost can be refund after order is confirmed.

. If the products are not based on the requirements, there will be the relevant compensations made for you.

4) What about the package and shipping time?

.Packing: As Customer's Requirements

.Shipping: We have various shipping ways for our customers, such as express which including TNT, DHL, FEDEX, UPS, EMS, etc. ; by air/ sea, and we are VIP of these express.

.Shipping time:

Normally small orders, it just 10-15 business days to arrive your hand; When comes to the customs declaration, it may need 7 days.

Other mass qty of Steel Frame Formwork , we send them out by sea or by air to sea port or air port to save some shipping freight for our customers. By ocean, it may need 45~60days, by air, it may need 25~40days.

- Q: Can steel frame formwork be used in areas with limited space?

- Areas with limited space can indeed utilize steel frame formwork. The flexibility and adaptability of steel frame formwork make it advantageous for various project needs, including confined spaces. Unlike conventional timber formwork, steel frame formwork is lightweight and can be effortlessly assembled and disassembled, making it well-suited for tight spaces. Moreover, the modular design of steel frame formwork permits customization and adjustment to accommodate specific dimensions, ensuring efficient space utilization. Consequently, steel frame formwork presents itself as a feasible choice for construction projects in areas with limited space.

- Q: Are there any limitations to the number of reuses for steel frame formwork panels?

- Yes, there are limitations to the number of reuses for steel frame formwork panels. While steel is a durable and strong material, it is not invincible and can deteriorate over time with repeated use. Some of the limitations include: 1. Fatigue: With each use, the steel frame formwork panels are subjected to various loads and stresses. Over time, this can lead to fatigue, causing the steel to weaken and eventually fail. 2. Corrosion: Steel is susceptible to corrosion when exposed to moisture, chemicals, or environmental conditions. Corrosion can weaken the structural integrity of the panels, making them less suitable for reuse. 3. Wear and tear: The repeated assembly, disassembly, and transportation of steel formwork panels can cause wear and tear. This can lead to deformation, cracks, or other damage, making the panels less effective and safe for reuse. 4. Surface imperfections: During the concrete pouring process, the formwork panels can experience surface imperfections such as scratches, dents, or concrete residue buildup. These imperfections can affect the quality of subsequent concrete pours and may require repair or replacement of the panels. 5. Changes in construction requirements: Over time, there may be changes in construction methods, designs, or building codes that render older steel formwork panels obsolete. This can limit their reuse as they may not meet the updated requirements. To ensure the safe and effective reuse of steel frame formwork panels, regular inspections, maintenance, and repairs are necessary. It is also important to follow manufacturer guidelines and industry best practices to determine the suitable number of reuses for each panel, taking into account its condition, history of use, and the specific construction project requirements.

- Q: What are the different types of release agents that can be used with steel frame formwork?

- There are several types of release agents that can be used with steel frame formwork, including petroleum-based release agents, water-based release agents, and silicone-based release agents. Each type has its own advantages and disadvantages, and the choice of release agent depends on factors such as the specific requirements of the project, the desired finish of the concrete surface, and environmental considerations.

- Q: What are the common safety guidelines for working with steel frame formwork systems?

- When working with steel frame formwork systems, there are several common safety guidelines that should be followed to ensure the well-being of workers. These guidelines include: 1. Personal Protective Equipment (PPE): All workers should wear appropriate PPE, including hard hats, safety glasses, gloves, and steel-toed boots. This helps protect against potential hazards such as falling objects and sharp edges. 2. Training and Competence: Workers should receive proper training on the safe use of steel frame formwork systems. They should be competent in understanding the equipment, its assembly, and disassembly procedures, as well as be aware of potential risks and how to mitigate them. 3. Inspection and Maintenance: Prior to use, all steel frame formwork systems should be inspected for any damage or defects. Regular maintenance should also be performed to ensure the equipment remains in good working condition. Any damaged or faulty components should be immediately replaced. 4. Proper Assembly and Disassembly: Careful attention should be given to the correct assembly and disassembly of the steel frame formwork systems. Workers should follow the manufacturer's instructions, ensuring that all components are securely connected and that the system is stable and level. 5. Fall Protection: When working at heights, fall protection measures should be in place. This may include using guardrails, safety nets, or personal fall arrest systems. Workers should be trained in the use of such systems and should always secure themselves to prevent falls. 6. Load Capacity: The load capacity of the steel frame formwork systems should never be exceeded. Workers should be aware of the maximum load limits and ensure that the equipment is not overloaded. This helps prevent structural failures and potential accidents. 7. Communication and Coordination: Effective communication and coordination among workers is essential to maintain a safe working environment. Clear instructions should be given, and workers should be aware of their roles and responsibilities. Regular safety briefings and toolbox talks can help reinforce safety practices. 8. Ergonomics: Adequate lifting techniques should be used to prevent strains or injuries. Workers should avoid overexertion and use proper lifting equipment when necessary. This helps prevent musculoskeletal injuries and promotes overall well-being. By following these common safety guidelines, workers can minimize the risks associated with working with steel frame formwork systems and ensure a safe and productive work environment.

- Q: How does steel frame formwork differ from other types of formwork?

- Steel frame formwork differs from other types of formwork in several ways. Firstly, steel frame formwork is made of steel, which makes it extremely strong and durable. It can withstand heavy loads and is resistant to warping or bending. This makes it ideal for construction projects that require a high level of strength and stability. Secondly, steel frame formwork is highly versatile. It can be easily customized and adjusted to fit different shapes and sizes of structures. This flexibility allows for the creation of complex and unique designs that may not be possible with other types of formwork. Additionally, steel frame formwork offers superior stability and accuracy. The steel frames provide excellent support and ensure that the formwork remains in place and does not shift during the pouring and curing of concrete. This results in better quality and more precise construction. Furthermore, steel frame formwork has a longer lifespan compared to other types of formwork. Its durability and resistance to wear and tear mean that it can be used for multiple projects, making it a cost-effective option in the long run. Lastly, steel frame formwork is relatively quick and easy to assemble and dismantle. The steel frames can be easily transported and assembled on-site, saving time and labor costs. This efficiency is especially beneficial for projects with tight deadlines or limited resources. In summary, steel frame formwork stands out from other types of formwork due to its strength, versatility, stability, durability, and ease of use. These qualities make it an excellent choice for construction projects that require a high level of performance and efficiency.

- Q: What are the different types of safety measures taken when working with steel frame formwork?

- To ensure the safety of workers and minimize the risk of accidents when working with steel frame formwork, it is important to take several safety measures. These measures include: 1. Wearing Personal Protective Equipment (PPE): Workers must always wear appropriate PPE, such as safety helmets, safety glasses, gloves, and steel-toed boots, to protect themselves from falling objects, flying debris, and potential foot injuries. 2. Implementing Fall Protection: Since steel frame formwork often involves working at heights, fall protection measures should be put in place. This may include using safety harnesses, guardrails, and safety nets to prevent falls and reduce the impact in case of an accident. 3. Ensuring Secure and Stable Work Platforms: The work platforms and scaffolding used should be securely erected and well-maintained to ensure stability and avoid collapse. Regular inspections should be conducted to identify any potential hazards or weaknesses. 4. Checking Load Capacity: Before using steel frame formwork, it is crucial to determine its load capacity and ensure that it is not exceeded. Overloading can result in structural failure and collapse, putting workers at risk. 5. Proper Installation and Dismantling: Trained and experienced workers should be responsible for installing and dismantling steel frame formwork, following proper procedures. This includes ensuring secure and stable connections, proper alignment, and adequate support. 6. Observing Electrical Safety: If electrical equipment is used alongside steel frame formwork, electrical safety measures should be followed. This includes using grounded tools, checking for exposed wires, and ensuring the good condition of electrical cords. 7. Emphasizing Communication and Training: Effective communication and comprehensive training are essential for maintaining a safe work environment. Workers should receive training on the correct use of steel frame formwork, safety procedures, emergency protocols, and potential hazards. 8. Conducting Regular Inspections: Regular inspections of the steel frame formwork should be carried out to identify any signs of wear and tear, damage, or potential hazards. Any issues should be addressed promptly to prevent accidents or failures. 9. Being Prepared for Emergencies: In the event of an emergency, workers should be aware of the locations of emergency exits, fire extinguishers, and first aid kits. Emergency response plans should be in place, and workers should be trained on how to respond to emergencies such as fires, injuries, or structural failures. By implementing these safety measures, the risks associated with working with steel frame formwork can be significantly reduced, ensuring the safety and well-being of the workers involved.

- Q: How does steel frame formwork accommodate for different concrete mix designs?

- Steel frame formwork offers great versatility as it can easily cater to different concrete mix designs. The steel frames are intelligently designed to allow for adjustments and modifications that meet the specific requirements of each concrete mix. To begin with, the steel formwork can be easily adjusted to accommodate various concrete mix designs by modifying the size and shape of the formwork panels. This can be achieved by either adding or removing sections of the steel frames or by utilizing adjustable panels that can be resized accordingly. These alterations guarantee that the formwork aligns perfectly with the dimensions and specifications of the concrete mix. Furthermore, steel frame formwork provides flexibility in terms of the desired surface finish for different concrete mix designs. The formwork can be adapted to incorporate a range of surface treatments like smooth finishes, textured finishes, or patterned finishes. This adaptability allows for different concrete mix designs to achieve the desired aesthetic and functional requirements. Additionally, steel frame formwork can effectively accommodate diverse concrete mix designs by integrating specific features or reinforcements. For instance, if a concrete mix necessitates additional support or reinforcement, the steel frames can be modified to include additional beams, braces, or tie rods. These reinforcements guarantee the structural integrity and stability of the formwork, enabling it to withstand the pressures and forces exerted by various concrete mix designs. In conclusion, steel frame formwork proves to be an incredibly flexible solution that easily caters to different concrete mix designs. The adjustability of the formwork panels, the flexibility in surface finish, and the ability to incorporate specific features or reinforcements ensure that the formwork is compatible with various concrete mix designs and can accurately meet the specific requirements of each project.

- Q: How does the cost of steel frame formwork compare to other types of formwork?

- The cost of steel frame formwork can vary based on various factors including project size and complexity, location, and market conditions. Generally, steel frame formwork tends to be more expensive compared to other formwork types. One reason for the higher cost is the material itself. Steel is a durable and strong material, making it ideal for supporting heavy loads and enduring harsh conditions. However, its strength and durability come at a higher price compared to materials like wood or plastic, commonly used in other formwork types. Moreover, skilled labor and specialized equipment are often necessary for the installation and removal of steel frame formwork. This increases the overall cost as it may require more time and resources compared to other formwork systems that are easier to handle and require less expertise. Despite the higher initial cost, steel frame formwork offers several advantages that can make it a cost-effective choice in certain situations. The durability and reusability of steel formwork can result in long-term savings as it can be used for multiple projects, reducing the need for frequent replacements. Furthermore, steel formwork provides excellent quality and precision, leading to smoother finishes and decreasing the need for additional labor or materials for finishing work. Ultimately, when considering the cost of steel frame formwork in comparison to other formwork types, it is crucial to assess the benefits it offers in relation to the initial investment. Factors such as project requirements, duration, and long-term use can impact the cost-effectiveness of steel frame formwork in different construction scenarios.

- Q: How does steel frame formwork help in achieving accurate concrete leveling?

- Achieving precise concrete leveling is made possible with the use of steel frame formwork, as it offers a rigid and stable structure for pouring and shaping the concrete. Designed to be strong and durable, the steel frames maintain their shape and alignment throughout the entire pouring process. One major advantage of steel frame formwork is the ability to have precise control over the concrete placement and leveling. The frames can be easily adjusted and aligned to the desired height and slope, ensuring accurate pouring. This eliminates any inconsistencies or unevenness in the final concrete surface. Furthermore, steel frame formwork provides exceptional support and stability, preventing any deformation or movement during the pouring and curing of the concrete. This guarantees that the concrete maintains its intended shape and level, even under the pressure of the wet mix and its own weight. Additionally, the steel frames minimize the risk of concrete shrinkage and settlement, which can occur if the formwork is not adequately supported. By providing a strong and rigid structure, the frames distribute the weight of the concrete evenly, reducing the chances of sinking or settling after curing. Moreover, steel frame formwork is highly adaptable and can be easily customized to fit various shapes and sizes of concrete structures. This allows for accurate leveling, even in complex and irregular designs. In conclusion, steel frame formwork is essential in achieving accurate concrete leveling by offering a stable and adjustable structure for pouring and shaping. Its strength, stability, and versatility ensure that the concrete maintains its desired level and shape, resulting in a high-quality and level finished surface.

- Q: How does steel frame formwork handle the placement of ramps and accessibility features within the concrete structure?

- Steel frame formwork is a versatile and efficient system that can easily accommodate the placement of ramps and accessibility features within a concrete structure. The steel frame formwork system consists of modular panels and adjustable props, which can be easily reconfigured to create the desired shape and dimensions required for ramps and other accessibility features. The panels of the steel frame formwork system are lightweight, yet sturdy, allowing for easy handling and installation. They can be easily adjusted to different heights and angles, making it possible to create ramps with varying slopes and inclinations. Additionally, the modular nature of the system allows for flexibility in design, enabling the inclusion of additional features such as handrails or non-slip surfaces to ensure the safety and accessibility of the structure. Furthermore, steel frame formwork provides excellent support and stability during the concrete pouring process. The adjustable props and tie rods ensure that the formwork remains in place and can withstand the pressure exerted by the wet concrete. This ensures that the ramp or any other accessibility feature is accurately formed and maintains its structural integrity. Moreover, steel frame formwork allows for efficient and easy removal once the concrete has cured and hardened. The formwork panels can be easily dismantled and reused for future construction projects, reducing waste and costs. This makes it a cost-effective and sustainable solution for incorporating ramps and accessibility features within a concrete structure. In conclusion, steel frame formwork is a highly adaptable and efficient system that effectively handles the placement of ramps and accessibility features within a concrete structure. Its modular design, adjustable components, and stability during the concrete pouring process make it an ideal choice for creating safe and accessible structures.

Send your message to us

1050 Series/750 Series Adjustable Steel Frame Formwork

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches