750 Series Adjustable Steel Frame Formwork with Special hollow steel

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

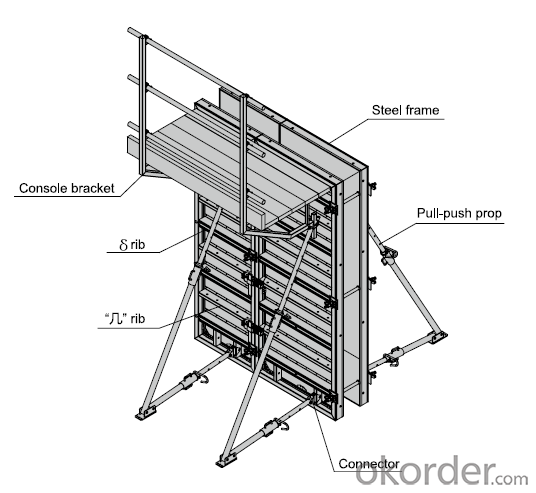

1. Structure of Steel Frame Formwork

There is a prizing part designed in the corner, which can help to position and remove formwork easily.

The plywood is screwed on from the back when connecting frame and plywood, so the surface of the finished concrete is perfect.

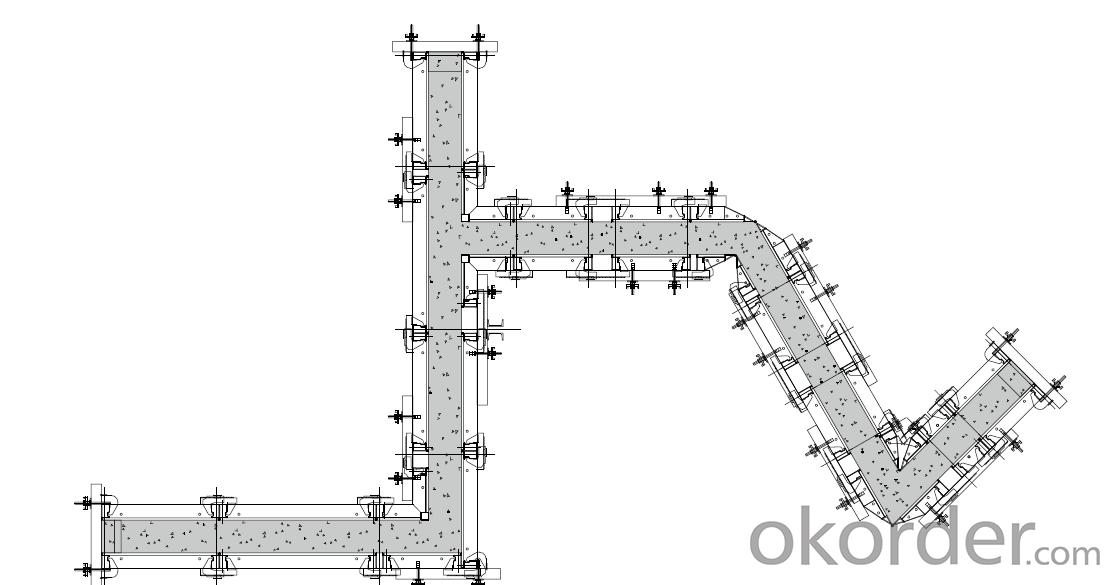

The formwork series are a complete system with a full set of accessories, and can be set up flexibly according to project demand.

2. Main Features of Steel Frame Formwork

Light weight

High strength

High standardized system

Easy connection with adjustable steel clamp

Convenient and fast corner formwork

Flexible to assemble and application

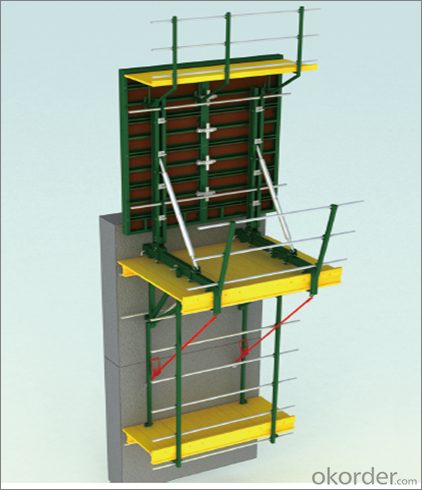

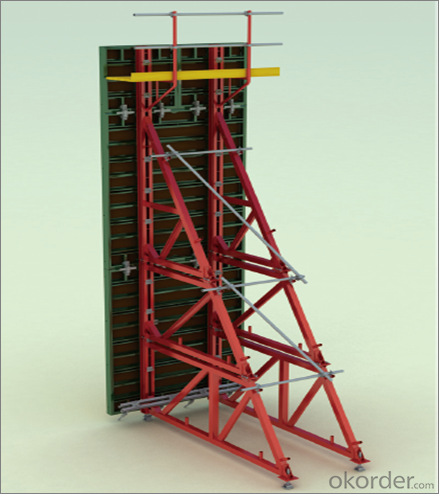

3. Steel Frame Formwork Images

4. Steel Frame Formwork Specification

-The steel frame formwork is plywood covered with hollow steel. The plywood is 18 mm thick.

-The frame is highly strengthened, and the wall formwork can bear lateral pressure 60 KN/m2 while the column formwork can bear 80 KN/m2.

-As a standardized system, it is flexible to assemble , wood batten can be filled to satisfy the need f of non-standard size.

-The adjustable steel clamp is convenient to use, and can hold tightly.

5. FAQ of Steel Frame Formwork

1) What can we do for you?

.We can ensure the quality of the vinyl banner and avoid extra expenses for customers.

.We can provide you the professional design team.

.We can provide fashionable and newest styles for you.

.We can design the artwork for you.

. Please feel free to customize.

2) What promises can be done by us?

. If interested in Steel Frame Formwork , please feel free to write us for any QUOTE.

. If printing required, please advise asap because the whole set need much more time to complete.

. Please DO check goods when courier knocks your door and contact us asap if any issue.

3) What about of our after-sale service?

. Response will be carried out in 24hours after receiving any complain or request.

. Steel Frame Formwork GK120 cost can be refund after order is confirmed.

. If the products are not based on the requirements, there will be the relevant compensations made for you.

4) What about the package and shipping time?

.Packing: As Customer's Requirements

.Shipping: We have various shipping ways for our customers, such as express which including TNT, DHL, FEDEX, UPS, EMS, etc. ; by air/ sea, and we are VIP of these express.

.Shipping time:

Normally small orders, it just 10-15 business days to arrive your hand; When comes to the customs declaration, it may need 7 days.

Other mass qty of Steel Frame Formwork , we send them out by sea or by air to sea port or air port to save some shipping freight for our customers. By ocean, it may need 45~60days, by air, it may need 25~40days.

- Q: Can steel frame formwork be used for water retaining structures?

- Water retaining structures can indeed utilize steel frame formwork. Renowned for their strength, durability, and ability to withstand high pressure and water loads, steel formwork systems are frequently employed in construction endeavors involving the creation of water tanks, reservoirs, swimming pools, and other structures necessitating water retention. Steel frame formwork is specifically engineered to remain impervious to water, thereby averting leakage and bolstering the structural soundness of the water retaining structure. Furthermore, the ease of assembly, disassembly, and reuse renders steel formwork a cost-effective choice for such projects. Nonetheless, it is crucial to implement appropriate waterproofing measures, such as employing sealants or membranes, to further heighten the structure's resistance to water.

- Q: Can steel frame formwork be used for healthcare and medical facilities construction?

- Yes, steel frame formwork can be used for healthcare and medical facilities construction. Steel frame formwork is known for its strength, durability, and versatility, making it suitable for various construction projects including healthcare and medical facilities. It provides a stable and secure framework that can support the weight of heavy concrete structures, ensuring the safety and stability of the building. Additionally, steel frame formwork can be easily assembled, disassembled, and adjusted, allowing for flexibility in design and efficient construction processes. Moreover, steel is a non-combustible material, which is important for healthcare and medical facilities that require high fire safety standards. Overall, steel frame formwork is a reliable and efficient choice for constructing healthcare and medical facilities.

- Q: Does steel frame formwork require any specific curing methods?

- No, steel frame formwork does not require any specific curing methods as it is primarily used for providing structural support during construction rather than for curing concrete.

- Q: What are the different types of formwork leveling systems used with steel frame formwork?

- There are several types of formwork leveling systems used with steel frame formwork, including adjustable props, leveling jacks, shims, and wedges. These systems are used to ensure that the formwork is accurately leveled and aligned before concrete pouring, allowing for the construction of strong and stable structures.

- Q: Are there any restrictions on the type of reinforcement that can be used with steel frame formwork?

- There exist certain limitations regarding the type of reinforcement permissible for utilization with steel frame formwork. The utilization of steel frame formwork is widespread in the construction domain due to its robustness and sturdiness. Nonetheless, it is imperative to guarantee the compatibility of the reinforcement employed with the steel frame formwork system. One limitation pertains to the dimensions and configuration of the reinforcement bars. The bars employed must be capable of fitting within the formwork system devoid of causing any obstructions or impediments to the pouring and solidification of the concrete. Additionally, adequate spacing between the reinforcement bars is necessary to facilitate appropriate consolidation of the concrete and ensure structural integrity. Another limitation concerns the type of material utilized for reinforcement. Steel frame formwork is conventionally designed to accommodate steel reinforcement bars, as these bars possess comparable properties and can be seamlessly integrated into the formwork system. Alternative reinforcement materials, such as fiberglass or carbon fiber, might not be suitable for use with steel frame formwork due to disparities in strength, compatibility, and bonding characteristics. It is crucial to adhere to the manufacturer's guidelines and recommendations when selecting and installing reinforcement in conjunction with steel frame formwork. This guarantees the appropriateness and compatibility of the reinforcement employed with the formwork system, thereby ensuring the structural stability and integrity of the construction project.

- Q: How does steel frame formwork affect the overall sustainability certifications of a building?

- A building's overall sustainability certifications can be significantly impacted in a positive manner by the use of steel frame formwork. Efficient resource utilization is a crucial aspect of sustainability, and steel frame formwork excels in this area. Steel, being a highly durable and recyclable material, can be reused multiple times without compromising its structural integrity. This reduces the need for new materials, minimizing the environmental impact associated with construction. Moreover, the use of steel frame formwork enhances construction efficiency. It enables faster assembly and disassembly, resulting in reduced construction time and minimal disruption to the surrounding environment. This can lead to lower energy consumption, as the construction phase is completed more swiftly. Additionally, steel frame formwork provides excellent strength and stability, allowing for the construction of taller and larger buildings. This optimizes land use and decreases the building's footprint, thereby contributing to a more sustainable urban environment. Furthermore, steel is resistant to fire, pests, and natural disasters, ensuring the longevity and safety of the building. This reduces the need for frequent repairs and replacements, resulting in lower maintenance costs and less waste generation. In terms of sustainability certifications like LEED (Leadership in Energy and Environmental Design), steel frame formwork can help earn points in various categories. These certifications typically prioritize energy efficiency, materials and resources, and innovative design. Steel frame formwork aids in achieving these objectives by reducing energy consumption during construction, utilizing recycled materials, and providing a durable and long-lasting structure. In conclusion, steel frame formwork positively impacts a building's sustainability certifications by promoting resource efficiency, reducing environmental impact, enhancing construction efficiency, and contributing to the durability and safety of the structure.

- Q: Can steel frame formwork be used in curved or irregular shapes?

- Indeed, curved or irregular shapes can be accommodated by employing steel frame formwork. The flexibility of steel frames enables effortless adjustments to accommodate various shapes and contours. Moreover, steel formwork can be tailored and manufactured according to precise project specifications, thus affording greater flexibility in constructing curved or irregular structures. The resilience and robustness of steel further render it suitable for deployment in intricate shapes, guaranteeing that the formwork can endure the pressure and forces exerted during the concrete pouring and curing process. All in all, steel frame formwork furnishes a versatile remedy for constructing curved or irregular shapes within the construction sector.

- Q: How does steel frame formwork contribute to better concrete curing in different weather conditions?

- Steel frame formwork contributes to better concrete curing in different weather conditions in several ways. Firstly, the steel frame provides stability and support to the formwork, ensuring that it remains intact and in place during adverse weather conditions such as heavy rain or strong winds. This prevents any potential damage or collapse of the formwork, ensuring the concrete is not exposed to the elements prematurely. Secondly, the steel frame formwork provides a barrier against moisture and temperature fluctuations, which are crucial factors in proper concrete curing. It helps to retain the moisture within the concrete, preventing excessive evaporation, especially in hot and dry weather conditions. This allows for a slower and more controlled curing process, reducing the risk of cracking or shrinkage. Additionally, the steel frame formwork allows for efficient insulation, which is beneficial in extreme weather conditions. It helps to maintain a stable temperature within the concrete, protecting it from freezing or overheating, which can adversely affect the curing process. Overall, the use of steel frame formwork provides a reliable and durable system that ensures proper concrete curing, regardless of the weather conditions. It helps to create a controlled environment for curing, resulting in stronger, more durable concrete structures.

- Q: How does steel frame formwork handle different types of formwork sealing techniques?

- Steel frame formwork is highly versatile and can easily accommodate various types of formwork sealing techniques. The steel frames provide a sturdy and rigid structure that can securely hold and support the formwork. Whether it is traditional sealing methods like rubber or plastic sealing strips, or advanced techniques like silicone sealants or foam tapes, the steel frame formwork can effectively handle them all. The strong and durable steel frames ensure that the formwork remains tightly sealed, preventing any leakage or seepage of concrete during the construction process.

- Q: Can steel frame formwork be used in high-rise construction?

- Yes, steel frame formwork can be used in high-rise construction. Steel frame formwork provides a strong and durable support system for casting concrete in high-rise structures. Its strength and stability make it suitable for handling the heavy loads and pressures involved in constructing tall buildings. Additionally, steel frame formwork offers flexibility in design and ease of assembly, making it a preferred choice for high-rise construction projects.

Send your message to us

750 Series Adjustable Steel Frame Formwork with Special hollow steel

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches