SF120 Adjustable Steel Frame Formwork with thickness of 18mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

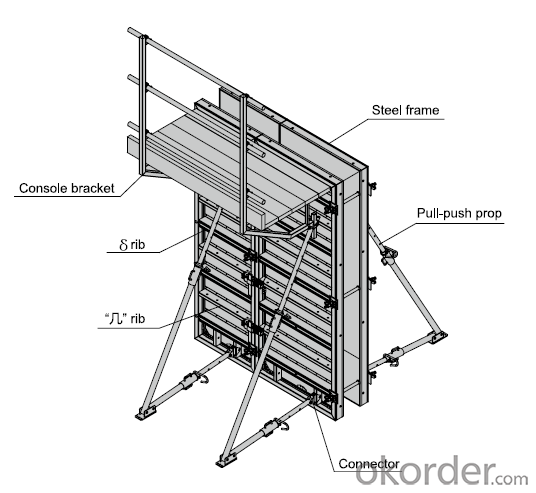

1. Structure of Steel Frame Formwork

There is a prizing part designed in the corner, which can help to position and remove formwork easily.

The plywood is screwed on from the back when connecting frame and plywood, so the surface of the finished concrete is perfect.

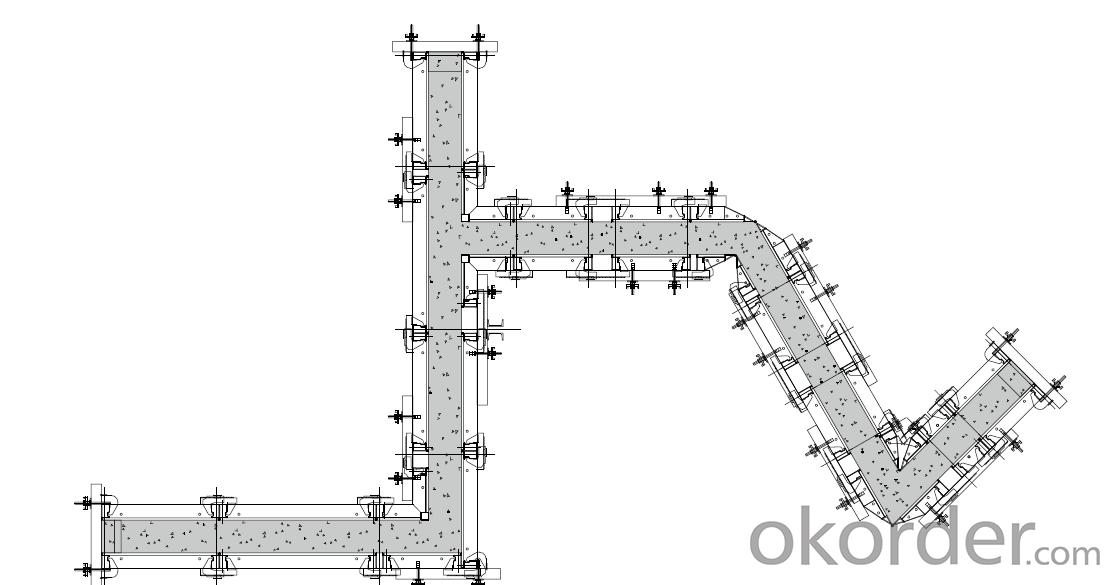

The formwork series are a complete system with a full set of accessories, and can be set up flexibly according to project demand.

2. Main Features of Steel Frame Formwork

Light weight

High strength

High standardized system

Easy connection with adjustable steel clamp

Convenient and fast corner formwork

Flexible to assemble and application

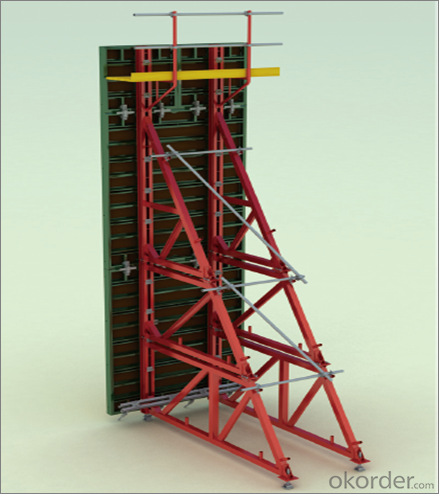

3. Steel Frame Formwork Images

4. Steel Frame Formwork Specification

-The steel frame formwork is plywood covered with hollow steel. The plywood is 18 mm thick.

-The frame is highly strengthened, and the wall formwork can bear lateral pressure 60 KN/m2 while the column formwork can bear 80 KN/m2.

-As a standardized system, it is flexible to assemble , wood batten can be filled to satisfy the need f of non-standard size.

-The adjustable steel clamp is convenient to use, and can hold tightly.

5. FAQ of Steel Frame Formwork

1) What can we do for you?

.We can ensure the quality of the vinyl banner and avoid extra expenses for customers.

.We can provide you the professional design team.

.We can provide fashionable and newest styles for you.

.We can design the artwork for you.

. Please feel free to customize.

2) What promises can be done by us?

. If interested in Steel Frame Formwork , please feel free to write us for any QUOTE.

. If printing required, please advise asap because the whole set need much more time to complete.

. Please DO check goods when courier knocks your door and contact us asap if any issue.

3) What about of our after-sale service?

. Response will be carried out in 24hours after receiving any complain or request.

. Steel Frame Formwork cost can be refund after order is confirmed.

. If the products are not based on the requirements, there will be the relevant compensations made for you.

4) What about the package and shipping time?

.Packing: As Customer's Requirements

.Shipping: We have various shipping ways for our customers, such as express which including TNT, DHL, FEDEX, UPS, EMS, etc. ; by air/ sea, and we are VIP of these express.

.Shipping time:

Normally small orders, it just 10-15 business days to arrive your hand; When comes to the customs declaration, it may need 7 days.

Other mass qty of Steel Frame Formwork , we send them out by sea or by air to sea port or air port to save some shipping freight for our customers. By ocean, it may need 45~60days, by air, it may need 25~40days.

- Q: What is the role of steel frame formwork in achieving a smooth concrete finish?

- The role of steel frame formwork in achieving a smooth concrete finish is crucial. Steel frame formwork is used to create a temporary mold or structure that holds the concrete in place while it cures and hardens. It provides support and stability to the wet concrete, preventing any deformation or cracks that may occur during the curing process. One of the main benefits of using steel frame formwork is its ability to provide a precise and accurate shape to the concrete. The steel frames are designed to be rigid and sturdy, ensuring that the concrete maintains its desired shape and dimensions. This is particularly important when constructing structures with complex designs or intricate details. Additionally, steel frame formwork helps to achieve a smooth concrete finish by minimizing surface imperfections. The rigid structure of the steel frames prevents any movement or shifting of the concrete, resulting in a consistent and even surface. This is especially important when the concrete surface needs to be visually appealing or when a smooth finish is required for functional purposes, such as in flooring or walls. Furthermore, steel frame formwork allows for easy removal and reuse. Once the concrete has cured and hardened, the formwork can be dismantled and removed, leaving behind a clean and finished concrete surface. The steel frames can then be cleaned and reused for future projects, reducing construction costs and minimizing waste. In conclusion, the role of steel frame formwork in achieving a smooth concrete finish is indispensable. It provides the necessary support and stability to ensure the concrete maintains its desired shape and dimensions, while also minimizing surface imperfections. By using steel frame formwork, construction projects can achieve high-quality and visually appealing concrete finishes.

- Q: How does steel frame formwork handle concrete pouring in rainy weather conditions?

- Steel frame formwork is a highly reliable and sturdy construction system that can effectively handle concrete pouring even in rainy weather conditions. The steel frame is designed to provide strong support and stability to the formwork, ensuring that it can withstand the pressure and weight of the wet concrete. In rainy weather, the steel frame formwork is generally covered with a waterproof membrane or tarp to protect the concrete from direct contact with water. This helps prevent the concrete from becoming diluted or washed away by the rain, which can compromise the quality and strength of the structure. Additionally, steel frame formwork is built with tight joints and connections, minimizing the risk of water seepage into the formwork. This helps maintain the integrity and shape of the concrete during the pouring process. The steel frame also provides a rigid structure that prevents any deformation or movement of the formwork, ensuring that the concrete is poured accurately and evenly. Moreover, the steel frame formwork system is designed with proper drainage channels and outlets to divert any excess water away from the concrete. This helps prevent water accumulation and ensures that the concrete sets properly without any water-related issues such as voids or weak spots. Overall, steel frame formwork is a reliable choice for concrete pouring in rainy weather conditions. Its robust construction, waterproofing measures, and efficient drainage system help maintain the quality and integrity of the concrete, ensuring a successful and durable construction project.

- Q: What are the main components of a steel frame formwork system?

- The steel frame formwork system is comprised of several key components. Firstly, the primary components are the steel frames which offer the necessary structural support and stability for the construction process. Constructed from high-quality steel, these frames are designed to withstand the weight and pressure of the poured concrete. Secondly, the steel frames are equipped with panels, typically made from durable materials such as plywood. These panels serve as the surface onto which the concrete is poured, providing the desired shape and finish to the structure. What's more, the panels can be easily removed and reused for multiple projects, making them a cost-effective choice. Next, adjustable props are utilized to support the steel frame formwork system and ensure its stability during the concrete pouring phase. These props can be adjusted to the desired height, offering flexibility when constructing structures of varying dimensions. Made from high-grade steel, these props are capable of withstanding heavy loads. In addition, tie rods are employed to hold the formwork system together and maintain its shape during the concrete pouring process. These rods are threaded and passed through holes in the panels, allowing for easy tightening or loosening as required. By providing extra strength and stability, the tie rods ensure that the formwork system maintains its shape until the concrete has fully cured. Lastly, wedges and clamps are used to securely fasten the panels to the steel frames, preventing any movement during the concrete pouring process. The wedges are inserted into slots on the frames and can be easily adjusted for a snug fit. Clamps are used to tightly secure the panels together, resulting in a solid and seamless formwork system. In summary, a steel frame formwork system consists of steel frames, panels, adjustable props, tie rods, wedges, and clamps. These components work in harmony to provide a robust and dependable solution for efficiently constructing various concrete structures.

- Q: What are the key considerations for selecting the appropriate steel frame formwork rental company?

- When selecting the appropriate steel frame formwork rental company, there are several key considerations to keep in mind. Firstly, it is important to consider the company's reputation and experience in the industry. Look for a company that has a proven track record of providing reliable and high-quality steel frame formwork rentals. Reading customer reviews and testimonials can give you insight into their reputation. Secondly, consider the range of formwork options that the company offers. Look for a company that has a diverse inventory of steel frame formwork, including different sizes and types to suit your specific project needs. Additionally, it is crucial to assess the company's reliability and availability. Ensure that they have a sufficient quantity of formwork available when you need it and that they have a reliable delivery and pick-up system. Cost is another important consideration. Compare the rental rates of different companies to ensure that you are getting a fair and competitive price. However, be wary of extremely low prices as they may indicate poor-quality formwork. Finally, look for a company that provides excellent customer service. They should be responsive to your inquiries and provide clear and detailed information about their products and services. A reliable and helpful customer service team can make the rental process smoother and more efficient. By considering these key factors, you can select the appropriate steel frame formwork rental company that meets your project requirements and ensures a successful construction process.

- Q: How does steel frame formwork prevent the formation of cold joints in the concrete?

- By offering a continuous support system throughout the pouring and curing process, steel frame formwork effectively prevents the formation of cold joints in concrete. Cold joints occur when fresh concrete is poured against hardened or partially hardened concrete, weakening the bond between the two sections. With steel frame formwork, the concrete is securely contained within a rigid structure, leaving no room for movement or displacement during pouring and curing. This eliminates any chance of cold joints forming. Moreover, the steel frame formwork enables proper alignment and positioning of reinforcing bars within the concrete. This ensures that the steel reinforcement is correctly placed and adequately covered with concrete, reducing the risk of cold joints around the reinforcement. Additionally, the steel frame formwork helps maintain the desired shape and dimensions of the concrete structure. Its sturdy and stable framework prevents any deformation or shifting that could result in cold joints. Furthermore, the steel frame formwork promotes uniform distribution of the concrete mix and aids in achieving a consistent surface finish. It allows for controlled pouring and compacting, reducing the likelihood of voids or air pockets that can lead to cold joints. In conclusion, the use of steel frame formwork provides a reliable and robust system for pouring concrete. It ensures proper containment and support, significantly reducing the risk of cold joint formation and resulting in a stronger and more durable concrete structure.

- Q: How does steel frame formwork contribute to the overall strength and stability of a concrete structure?

- Steel frame formwork plays a crucial role in enhancing the overall strength and stability of a concrete structure in various ways. Firstly, the steel frame provides a rigid and robust framework that acts as a support system for the concrete during the pouring and curing process. This ensures that the concrete is properly contained and shaped, preventing any sagging, bulging, or deformation that could weaken the structure. Additionally, the steel frame formwork allows for precise and accurate placement of the concrete, ensuring uniformity and consistency throughout the structure. This helps to eliminate any potential weak spots or inconsistencies that could compromise the overall strength. Furthermore, the steel frame formwork provides excellent resistance to external forces such as wind, seismic activity, or heavy loads. Its high tensile strength and durability make it capable of withstanding these forces, thereby enhancing the overall stability of the concrete structure. Moreover, steel frame formwork facilitates the proper curing of the concrete by providing a controlled environment. This controlled environment minimizes the risk of shrinkage, cracking, or moisture-related issues, which can significantly weaken the structure over time. By allowing for a consistent and controlled curing process, the steel frame formwork contributes to the long-term strength and durability of the concrete structure. In summary, steel frame formwork contributes to the overall strength and stability of a concrete structure by providing a rigid support system, ensuring uniformity and accuracy in placement, resisting external forces, and facilitating proper curing. Its robustness and durability make it an essential component in the construction process, ultimately enhancing the structural integrity and longevity of the concrete structure.

- Q: How does steel frame formwork contribute to better formwork stability in seismic zones?

- Steel frame formwork contributes to better formwork stability in seismic zones in several ways. Firstly, steel frame formwork is made of high-strength steel, which provides a strong and durable structure. This strength is crucial in seismic zones where the ground experiences high levels of shaking and lateral forces. Unlike other materials like wood or aluminum, steel is able to withstand these forces and maintain its structural integrity. Secondly, steel frame formwork is designed with specific features to enhance stability in seismic zones. It often includes additional bracing and reinforcement elements that help distribute the seismic forces evenly throughout the formwork system. These reinforcements prevent the formwork from collapsing or deforming during an earthquake and ensure that it can safely support the weight of the concrete being poured. Furthermore, steel frame formwork is highly adjustable and customizable. This allows it to be tailored to the specific requirements of a seismic zone. The formwork can be easily modified to accommodate different shapes and sizes of concrete structures, which is important in earthquake-prone areas where buildings may have irregular designs to withstand seismic forces. Additionally, steel frame formwork is reusable, which makes it a cost-effective solution in seismic zones. After each use, the formwork can be disassembled, inspected, and reassembled for the next project. This reduces the need for constant replacement and minimizes waste, making it an environmentally-friendly option as well. Overall, steel frame formwork provides superior stability in seismic zones due to its high-strength construction, additional reinforcements, adjustability, and reusability. Its ability to withstand the forces generated by earthquakes ensures the safety and integrity of the concrete structures being constructed in these areas.

- Q: What is the meaning of steel frame support structure?What is the support?

- It has good seismic performance and large lateral stiffness, so it is more commonly used in high-rise steel structure buildings, such as the structural form of steel braced frame system, such as central support, eccentric support and energy dissipation brace

- Q: How does steel frame formwork affect the overall flexibility of construction schedules?

- Steel frame formwork can have a significant positive impact on the overall flexibility of construction schedules. Due to its modular nature and quick assembly, steel frame formwork allows for faster construction progress, enabling projects to be completed within tighter timeframes. This increased speed and efficiency can help construction schedules to be more flexible and adaptable, as any unexpected delays or changes can be accommodated more easily. Additionally, the strength and durability of steel frame formwork ensure a stable and reliable construction process, further contributing to the overall flexibility of the schedule.

- Q: What are the different types of formwork chamfer solutions available for steel frame formwork systems?

- Some of the different types of formwork chamfer solutions available for steel frame formwork systems include chamfer strips, chamfer profiles, and chamfer blocks. These solutions are used to create beveled or angled edges on the concrete formwork, resulting in smooth and precise corners. Chamfer strips are typically made of plastic or rubber and can be easily attached to the formwork to create the desired chamfered edge. Chamfer profiles are pre-formed strips or profiles that are fixed onto the formwork to achieve consistent chamfer dimensions. Chamfer blocks are reusable blocks that are placed at the corners of the formwork to create chamfered edges. Overall, these chamfer solutions offer flexibility and efficiency in achieving high-quality finishes for steel frame formwork systems.

Send your message to us

SF120 Adjustable Steel Frame Formwork with thickness of 18mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords