Steel Frame Formwork with Thickness of 18mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

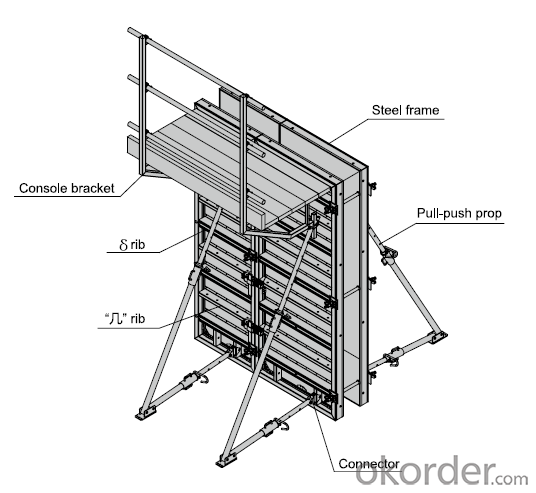

1. Structure of Steel Frame Formwork

There is a prizing part designed in the corner, which can help to position and remove formwork easily.

The plywood is screwed on from the back when connecting frame and plywood, so the surface of the finished concrete is perfect.

The formwork series are a complete system with a full set of accessories, and can be set up flexibly according to project demand.

2. Main Features of Steel Frame Formwork

Light weight

High strength

High standardized system

Easy connection with adjustable steel clamp

Convenient and fast corner formwork

Flexible to assemble and application

3. Steel Frame Formwork Images

4. Steel Frame Formwork Specification

-The steel frame formwork is plywood covered with hollow steel. The plywood is 18 mm thick.

-The frame is highly strengthened, and the wall formwork can bear lateral pressure 60 KN/m2 while the column formwork can bear 80 KN/m2.

-As a standardized system, it is flexible to assemble , wood batten can be filled to satisfy the need f of non-standard size.

-The adjustable steel clamp is convenient to use, and can hold tightly.

5. FAQ of Steel Frame Formwork

1) What can we do for you?

.We can ensure the quality of the vinyl banner and avoid extra expenses for customers.

.We can provide you the professional design team.

.We can provide fashionable and newest styles for you.

.We can design the artwork for you.

. Please feel free to customize.

2) What promises can be done by us?

. If interested in Steel Frame Formwork , please feel free to write us for any QUOTE.

. If printing required, please advise asap because the whole set need much more time to complete.

. Please DO check goods when courier knocks your door and contact us asap if any issue.

3) What about of our after-sale service?

. Response will be carried out in 24hours after receiving any complain or request.

. Steel Frame Formwork GK120 cost can be refund after order is confirmed.

. If the products are not based on the requirements, there will be the relevant compensations made for you.

4) What about the package and shipping time?

.Packing: As Customer's Requirements

.Shipping: We have various shipping ways for our customers, such as express which including TNT, DHL, FEDEX, UPS, EMS, etc. ; by air/ sea, and we are VIP of these express.

.Shipping time:

Normally small orders, it just 10-15 business days to arrive your hand; When comes to the customs declaration, it may need 7 days.

Other mass qty of Steel Frame Formwork , we send them out by sea or by air to sea port or air port to save some shipping freight for our customers. By ocean, it may need 45~60days, by air, it may need 25~40days.

- Q: Can steel frame formwork be used in marine or coastal construction?

- Yes, steel frame formwork can be used in marine or coastal construction. Steel is a durable and corrosion-resistant material that can withstand the harsh conditions present in marine environments. It provides the necessary strength and stability for concrete structures in coastal areas, making it a suitable choice for formwork.

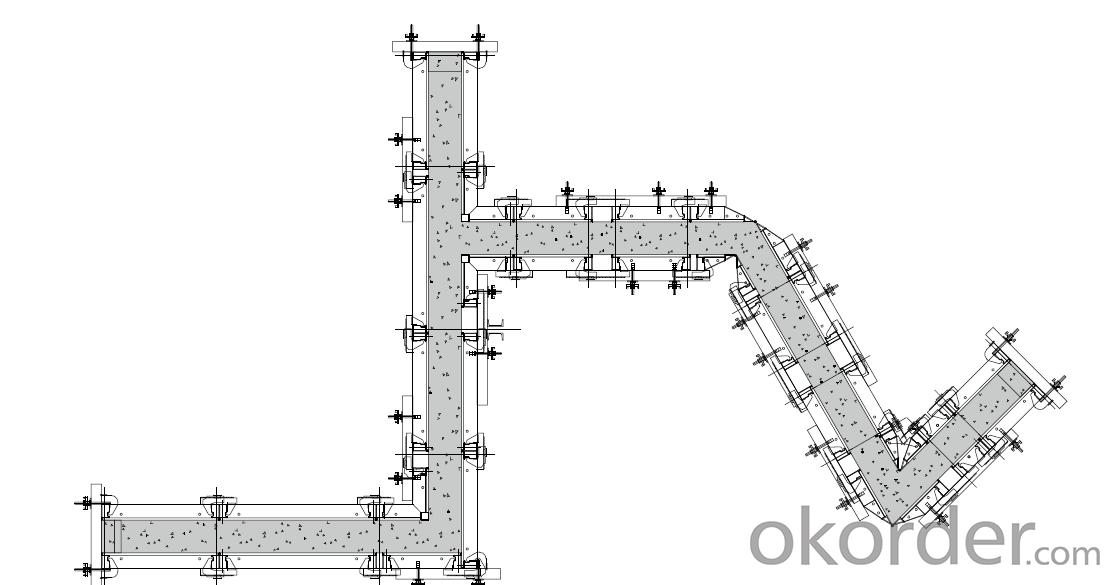

- Q: Can steel frame formwork be used in curved or irregular structures?

- Indeed, curved or irregular structures can utilize steel frame formwork. With its exceptional adaptability in terms of shape and design, steel frame formwork proves to be fitting for such structures. The steel frames can effortlessly be modified and curved to achieve the desired shape, enabling the creation of distinctive and intricate structures. Furthermore, steel frame formwork guarantees utmost strength and stability, thus safeguarding the structural integrity of curved or irregular structures. All in all, steel frame formwork presents itself as a flexible and trustworthy option for the construction of curved or irregular structures.

- Q: Can steel frame formwork be used in projects with limited construction site security or theft risks?

- Steel frame formwork is suitable for projects with limited construction site security or theft risks. It is renowned for its durability and strength, rendering it a dependable option for construction projects. This formwork offers a stable and secure structure that can withstand various external factors, including theft risks. Furthermore, it can be effortlessly locked and secured, reducing the likelihood of theft or unauthorized entry to the construction site. Nevertheless, it is crucial to acknowledge that projects with limited construction site security may necessitate additional security measures to safeguard the materials and equipment on-site.

- Q: How does steel frame formwork contribute to the overall durability of a concrete structure?

- The construction of concrete structures heavily relies on steel frame formwork, which plays a vital role in ensuring their durability. This formwork type offers multiple advantages that contribute to the strength and longevity of the concrete structure. To begin with, steel frame formwork provides exceptional strength and rigidity, enabling it to withstand the pressures and loads imposed during concrete pouring and curing. The design of the steel frames ensures robust support, preventing any deformation or collapse during the pouring process. This guarantees the even distribution and proper compaction of the concrete, resulting in a more durable structure. Moreover, steel frame formwork exhibits high resistance to corrosion, which is a major concern for concrete structures exposed to harsh environmental conditions or high moisture levels. Unlike other formwork materials, steel does not deteriorate over time due to moisture or chemical exposure. This corrosion resistance enhances the durability of the concrete structure, ensuring its long-term stability and structural integrity. Additionally, the precise dimensional accuracy offered by steel frame formwork plays a crucial role in the overall durability of the concrete structure. The manufacturing of the steel frames involves high precision, ensuring that the concrete is poured in the exact shape and dimensions required for the structure. This level of accuracy minimizes potential defects or weaknesses in the concrete, resulting in a more durable and structurally sound final product. Furthermore, steel frame formwork facilitates easy and efficient construction, reducing overall construction time and costs. The reusable nature of steel frames allows them to be used multiple times, making them a cost-effective choice for large-scale projects. This construction efficiency not only saves time and money but also ensures that the concrete structure is completed promptly, minimizing potential damage or deterioration caused by prolonged exposure to the elements. In conclusion, steel frame formwork significantly contributes to the overall durability of a concrete structure by providing strength, corrosion resistance, dimensional accuracy, and efficient construction. By utilizing steel frame formwork, construction professionals can ensure that the concrete structure is built to last, withstanding the test of time and various environmental factors.

- Q: Can steel frame formwork be used for both interior and exterior structures?

- Both interior and exterior structures can utilize steel frame formwork. This flexible and sturdy system is commonly employed in construction for a variety of structures, such as buildings, bridges, and tunnels. Its strength and stability make it suitable for applications in both interior and exterior settings. When constructing interior structures, steel frame formwork can be employed to build walls, columns, and slabs. It provides a robust and rigid framework that can withstand the pressure of pouring concrete, ensuring the desired shape and dimensions of the structure. The steel frames can be easily assembled and disassembled, allowing for efficient and rapid construction. Similarly, steel frame formwork is well-suited for exterior structures. It can be used to construct external walls, facades, and other components of the building envelope. The steel frames are resistant to weather conditions and can endure the elements, making them a dependable choice for exterior construction. Additionally, steel frame formwork can be customized to create intricate architectural shapes and designs, enhancing the aesthetic appeal of the structure. Overall, steel frame formwork is a versatile solution that can be employed for both interior and exterior structures. Its strength, durability, and flexibility make it an ideal choice for a wide range of construction projects.

- Q: Can steel frame formwork be used in areas with high wind loads?

- Yes, steel frame formwork can be used in areas with high wind loads. Steel is a strong and durable material that can withstand high winds and provide stability to the formwork system. However, additional measures such as bracing and anchoring may be required to enhance the stability and safety of the formwork in areas with extreme wind conditions.

- Q: How does steel frame formwork contribute to the overall versatility of a construction project?

- Steel frame formwork is a valuable asset in construction projects as it significantly enhances the overall versatility of the project. One of the key contributions of steel frame formwork is its ability to adapt to various project requirements and designs. The steel frames can be easily customized and adjusted to accommodate different shapes, sizes, and dimensions, thus allowing for the construction of complex structures and architectural features. Furthermore, steel frame formwork offers excellent structural stability and strength, which enables it to withstand high loads and pressures during the concrete pouring process. This durability is crucial for constructing tall buildings, bridges, or other large-scale structures that may be subjected to significant stresses. The steel frames ensure that the formwork maintains its shape and integrity, preventing any deformation or collapse that could compromise the project's progress and safety. Another advantage of steel frame formwork is its reusability. Unlike traditional timber formwork, steel frames have a longer lifespan and can be utilized on multiple projects, thereby reducing construction costs and waste. This reusability also contributes to the overall sustainability of the project, as it minimizes the consumption of natural resources and reduces the environmental impact associated with formwork disposal. Moreover, steel frame formwork offers flexibility in terms of assembly and disassembly. The frames can be easily assembled and dismantled, allowing for efficient and quick formwork installation and removal. This adaptability saves time and labor, leading to increased productivity and reduced construction timelines. Additionally, steel frame formwork provides a smooth and high-quality finish to the concrete surface. The rigid structure of the frames ensures that the formwork remains stable and level during the pouring process, resulting in a precise and consistent finish. This is particularly important for projects that require a high level of accuracy and aesthetics, such as architectural structures or exposed concrete surfaces. In conclusion, steel frame formwork greatly contributes to the overall versatility of a construction project by providing adaptability, durability, reusability, flexibility, and a superior finish. Its ability to accommodate various project requirements, withstand high loads, and offer cost-saving and sustainable solutions make it an indispensable tool for modern construction projects.

- Q: Can steel frame formwork be used for the construction of agricultural buildings?

- Yes, steel frame formwork can be used for the construction of agricultural buildings. Steel frame formwork is known for its strength, durability, and versatility, making it suitable for various construction projects, including agricultural buildings. It provides a robust framework for pouring concrete and can withstand the demands of agricultural environments. Additionally, steel formwork is reusable, cost-effective, and can be easily adapted to different design requirements, making it a practical choice for constructing agricultural buildings.

- Q: How does steel frame formwork affect the overall constructability of a concrete structure?

- The overall constructability of a concrete structure can be greatly enhanced by steel frame formwork. This formwork system comprises steel frames, typically made from steel beams or columns, which are utilized to bear the weight of the concrete during the pouring and curing process. One key advantage of steel frame formwork lies in its strength and durability. Steel possesses a high load-bearing capacity, enabling the formwork to withstand the pressure exerted by the wet concrete. Consequently, steel frame formwork allows for the construction of larger and taller concrete structures with ease, as it supplies the necessary support and stability. Moreover, steel frame formwork offers flexibility in terms of design and layout. The modular nature of the steel frames facilitates simple assembly and disassembly, rendering it suitable for various types of structures. This adaptability proves particularly advantageous when working on projects with intricate shapes or irregular layouts, as the formwork can be tailored to meet specific requirements. Furthermore, steel frame formwork enables faster construction times. The reusable nature of the steel frames permits easy transportation and reassembly at different locations, reducing the need for new formwork materials. This not only saves time, but also decreases construction costs. Additionally, the smooth surface of steel formwork allows for swifter and easier concrete pouring and finishing, resulting in shorter construction schedules. Another benefit of steel frame formwork is its ability to enhance the quality of the concrete structure. The rigid steel frames ensure precise alignment and dimensions, minimizing the risk of deformities or inconsistencies in the final structure. This contributes to improved overall aesthetics and structural integrity. To summarize, steel frame formwork has a positive impact on the overall constructability of a concrete structure due to its strength, durability, versatility, speed, and enhanced quality. Its capacity to support larger and more complex structures, combined with its ease of assembly and reusability, make it a favored choice for many construction projects.

- Q: What are the different types of safety nets and fall protection systems used with steel frame formwork?

- To ensure worker safety, various safety nets and fall protection systems are commonly employed alongside steel frame formwork. These systems serve to prevent falls from heights and establish a secure working environment. Among the safety nets utilized with steel frame formwork, the perimeter safety net is prevalent. It encompasses the work area's perimeter, capturing any falling objects and preventing their descent to the ground or workers below. Typically crafted from robust materials like high-strength nylon or polypropylene, the perimeter safety net is engineered to withstand substantial impacts. Its presence is vital in averting accidents and injuries caused by falling debris. Another fall protection system employed with steel frame formwork is the safety harness and lanyard system. This system comprises a comprehensive body harness worn by workers, which connects to an anchorage point using a lanyard. By distributing the force of a fall across the worker's body, the harness reduces the risk of injury. Lanyards, usually composed of resilient materials such as nylon or polyester, are designed to absorb fall energy. In addition to safety nets and harness systems, guardrails find common usage in conjunction with steel frame formwork. These barriers encircle the work area's perimeter, preventing inadvertent worker falls. Constructed from durable materials like high-strength steel or aluminum, guardrails are engineered to withstand significant impacts. They serve as a physical barrier, continuously reminding workers of the potential hazards associated with working at heights. Lastly, safety platforms are frequently deployed alongside steel frame formwork to provide workers with stable and secure surfaces. Fabricated from steel or aluminum, these platforms are easily installed and removed. By offering a level area for workers to stand on while operating at heights, safety platforms reduce the risk of slips and falls. In conclusion, safety nets, harness systems, guardrails, and safety platforms constitute the various fall protection systems employed alongside steel frame formwork. These systems play a crucial role in averting falls from heights and ensuring workers' safety on construction sites.

Send your message to us

Steel Frame Formwork with Thickness of 18mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords