Stainless Steel Drilling Bits

Stainless Steel Drilling Bits Related Searches

Stainless Steel Drill Bits Drill Bits For Stainless Steel Stainless Steel Drill Bit Drill Bit Stainless Steel Stainless Steel Bit Stainless Steel Drilling Steel Grinding Bits Drilling Stainless Steel Stainless Steel Drill Drill Stainless Steel Stainless Steel Pins Drilling Into Stainless Steel Drill Through Stainless Steel Stainless Steel Pipes Step Bit For Stainless Steel Stainless Steel Clips Stainless Steel Piping Stainless Steel Strips Stainless Steel Trim Strips Stainless Steel Pitting Stainless Steel Scissors Stainless Steel Elements Stainless Steel Sets Stainless Steel Drain Stainless Steel Dumbbells Stainless Steel Dowel Pins Stainless Steel Safety Pins Stainless Steel Frets Stainless Steel Wires Stainless Steel BinStainless Steel Drilling Bits Supplier & Manufacturer from China

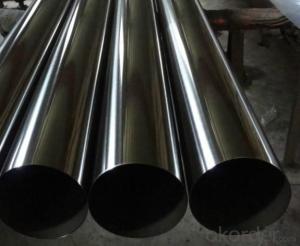

Stainless Steel Drilling Bits are precision tools designed for drilling holes in stainless steel materials. These bits are made from high-quality materials to ensure durability and long-lasting performance, making them ideal for various industrial applications. They are specifically engineered to withstand the hardness and resistance of stainless steel, providing clean and accurate holes with minimal wear and tear.Stainless Steel Drilling Bits are widely used in industries such as construction, manufacturing, and automotive, where precision and quality are paramount. They are essential for tasks like creating holes for screws, bolts, and other fasteners, as well as for cutting through metal components during assembly or repair. These bits can be used in both manual and power tools, depending on the specific requirements of the job at hand.

Okorder.com is a leading wholesale supplier of Stainless Steel Drilling Bits, offering a vast inventory to cater to the needs of businesses and professionals. With a commitment to quality and customer satisfaction, Okorder.com ensures that each Stainless Steel Drilling Bit is manufactured to the highest standards, providing reliable and efficient solutions for drilling in stainless steel materials.