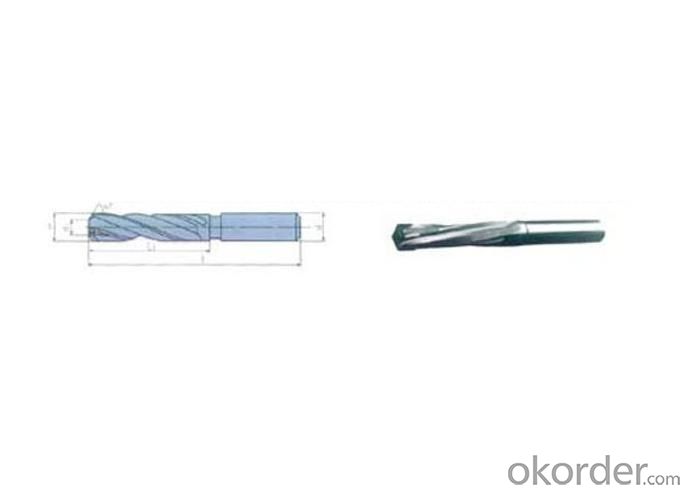

Flute Reamer

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 Pieces pc

- Supply Capability:

- 1000 Pieces per Month pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Detailed Product Description

1.Good quality

2.Welding hard alloy hole machining tools

3.Competitive price

4.Excellent after-sales service

Flute Reamer

Order No. |

D(h8) |

d(h9) |

d1 |

L |

L1 |

1111·001/1000087 |

10.00 |

10.0 |

6.5 |

133 |

87 |

1075094 |

10.75 |

10.0 |

7.1 |

142 |

94 |

1100094 |

11.00 |

10.0 |

7.1 |

142 |

94 |

1175094 |

11.75 |

10.0 |

7.1 |

142 |

94 |

1200101 |

12.00 |

12.0 |

7.8 |

151 |

101 |

1275101 |

12.75 |

12.0 |

8.1 |

151 |

101 |

1300101 |

13.00 |

12.0 |

8.4 |

151 |

101 |

1375108 |

13.75 |

12.0 |

9.1 |

160 |

108 |

1400108 |

14.00 |

12.0 |

9.1 |

160 |

108 |

1475114 |

14.75 |

12.0 |

9.7 |

169 |

114 |

1500114 |

15.00 |

12.0 |

9.7 |

169 |

114 |

1575120 |

15.75 |

12.0 |

10.4 |

178 |

120 |

1600120 |

16.00 |

16.0 |

10.4 |

178 |

120 |

1675125 |

16.75 |

16.0 |

11.0 |

184 |

125 |

1700125 |

17.00 |

16.0 |

11.0 |

184 |

125 |

1775130 |

17.75 |

16.0 |

11.7 |

191 |

130 |

1800130 |

18.00 |

16.0 |

11.7 |

191 |

130 |

1870135 |

18.70 |

16.0 |

12.3 |

198 |

135 |

1900135 |

19.00 |

16.0 |

12.3 |

198 |

135 |

1970140 |

19.70 |

16.0 |

13.0 |

205 |

140 |

2000140 |

20.00 |

20.0 |

13.0 |

205 |

140 |

- Q: Please enlighten brother snow reamer 150125110 motorcycle valve is not universal and how the hinge valve

- Motorcycle valve reamer is a set of the above several cars can be common.Reaming the valve is the best way to find a local repair car or motorcycle master, which is not clear here.Generally use 75 degrees, then 15 degrees and 45 degrees of reamer, and finally the effect after reaming, and then use several tools to trim. Use 45 degrees to the right contact width of reamer, reamer can take 15 degrees contact hinge low 75 degree knife to contact surface to improve the contact surface, preferably 1 mm or so, if it is too wide for 15 degrees and 75 degrees of cutting narrow. After reaming, grind the valve and check the seal.

- Q: Four what are the advantages of titanium blade reamer

- After TIN plating, the blade life is prolonged, and secondly, the machining ability is improved. If the titanium plating, then do not use cutting fluid. Cost saving.

- Q: In the lathe, with a floating reamer machining material for cast iron, diameter of 55mm hole, leaving margin 0.1mm, lathe speed is appropriate!!

- Reaming is actually the lower the speed, the better, but to balance with efficiency. So, according to the actual choice of 30-120

- Q: Do reamers and drills for machining centers use one hilt?

- One hilt is fine, of course. For example, using ER20 is fine, and the accuracy is fine!

- Q: Why are the dimensions of the reamer larger than the size of the hole?

- The reamer is fine cutting tools a certain size of the hole, the hole in finishing before must leave the finishing allowance, so the hole than the knife which small dumplings,What this says is positive solution. What you ask is very mechanical.

- Q: What's the difference between a bore cutter and a reamer?

- Two kinds of tools are expanding use, the cutter head is multi edge twist, on the big hole diameter expanding much, bore in the bottom aperture knife can be changed based on flexible, convenient adjustment, cost savings!

- Q: Use and do not use the threaded hole reamer reamer, what do you mean, how to choose the aperture

- Because the drill hole drilling accuracy is not high, the hole is rough, and the internal hole accuracy requirements are relatively high, reaming can improve the accuracy of the hole and the surface roughness of the hole.When machining threads, the drilling diameter is approximately the nominal diameter of the thread minus the pitch of the thread.

- Q: When reaming the piston pin hole and connecting rod copper sleeve, how much is the pin allowance?

- For better reference data, please Baidu search, Li Hao CNC tools, data on reamer tolerances and machining allowances

- Q: Difference between milling cutter and reamer

- Besides they say, the most intuitive is that the blade part of machine reamer is very short, while the neck is very long, so it looks like a long dumbbell.The end mills have longer cutter teeth, accounting for 1/2~2/3 of the overall length of the tool, and the neck is short. The cutter tooth is spiral and has fewer teeth. It looks sharp.People who don't know much about knives do so.

- Q: What's the result of the reaming of the inside hole of the reamer?

- You are using manual reaming Reaming, or drilling reaming? General artificial hand reaming, as long as the hands evenly twisted out of holes is not elliptic, if two handed force is not uniform, then wring out the hole could be elliptical; if you are using drilling reaming, drilling machine main shaft the hole is not concentric with the workpiece, the reamer reaming when leans to one side with Jin twisted down hole was wrung may be ellipse.

1. Manufacturer Overview

| Location | Shaanxi,China |

| Year Established | 2010 |

| Annual Output Value | Below US$1 Million |

| Main Markets | |

| Company Certifications |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | |

| Export Percentage | 1% - 10% |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b) Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Flute Reamer

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 Pieces pc

- Supply Capability:

- 1000 Pieces per Month pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches