ZYC series ZYC800B-B multi-functional Hydraulic Static Pile Driver

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 1000 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

ZYC series multi-functional Hydraulic Static Pile Driver

Features:

Main product: ZYC series multi-functional Hydraulic Static Pile Driver Self-developed with 5 up-to-date patents.

The working principle is using hydraulic pressure to clamp precasted pile, H shape or other shape steel pile, and then driving the pile into ground by hydraulic pressing.

Suitable for piling precast round & square concrete pile, H shape steel pile and other irregular-shaped pile in clay, soft soil and sandy ground.

It has characteristics of no noise, no vibration, no pollution, clear ground with high speed of pile driving, reliable construction quality and environmental protection, high efficiency, energy saving. It is welcomed by the customers with wide market prospect.

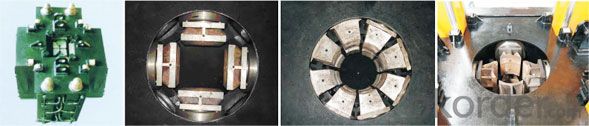

● Flexible connection technology

Novel flexible connection technology of central axis, won national practical patent

● Multi-functional piling technology

Original combination clamping piling and top piling won invention patent

● Inverted cylingder technology

Structure design of inverted cylinder changes strained condition of cylinder and increases the service life of cylinder, won national practical patent

● Integrative side and corner piling technology

Particular side and corner piling mechanism increasing the capability of side & corner piling and won national practical patent

Self-adaptive clamping mechanism

Original self-adaptive clamping mechanism won national practical patent

Parameters:

| Rated piling pressure(tf) | 800 | suitable pile & specification(mm) | ¢300-800 | |

| Max. Piling speed(m/min) | 6.5 | Max. Crane lifting weight(t) | 16 | |

| Piling stroke(m) | 2.0 | Hanging pile length(m) | 15 | |

| Max. Longitudinal pace(m) | 3.6 | Minimum side piling space(mm) | 1380 | |

| Max. Transverse pace(m) | 0.6 | Minimum corner piling space(mm) | 2800 | |

| Max. Rise stroke(m) | 1.1 | Intensity of pressure(tf/m²) | 15.0/20.2 | |

| Max.rotation angle per time(°) | 11 | Weight composition | (t) Machine weight | 203±3 |

| Rated hydraulic system pressure(mpa) | 25(20) | Added water weight(t) | 48 | |

| Hydraulic Pump (Unit × Ml/Turn) | 2×125+2×80 | Counter weight(t) | 549 | |

| Motor power (Unit × kw) | 3×37+1×30 | Total weight(t) ≥ | 800 | |

FAQ

To provide customers with professional and technical services, to meet the demands of customers for construction efficiency and cost control, to achieve value for customers, which is the constant pursuit of Toppile, Toppile implant this concept in the whole process of sales and services.

Before sales

Research market with customers; provide technical advice, customized design and production.

On sales

Always communicate and adjust of design with customer to ensure the product satisfy all requirements.

After sales

Provide installation, adjustment, maintenance service, create customers files, following up machine working situation, provide customer a whole set of “Butler” and “Gapless”services.

Value added services

Redesign and upgrade the hydraulic system of piling machine, upgrade structure components.

Provide high quality and lower price components.

Toppile is the agent of many components factories, including cylinders, pumps, seals, hydraulic elements.

Company Information

China National Building Materials Group Corporation is the full name of CNBM, which is one of the largest state-owned group in China. In 2013, the total asset of CNBM exceeds US$60 billion dollars with a total staff of 180,000. CNBM is listed in the World Top 500 Enterprises!

CNBM International works as the international platform for CNBM Group. In 2013, our total sales income was more than US$16.8 billion dollars.Every year we import large quantity of iron ore, coking coal and thermal coal etc from India, Brazil, Australia and Russia and other countries.ld'>Our major responsibility is international marketing of different construction machinery & formwork, including lifting machinery, concrete machinery, earthmoving machinery, brick/block machinery; steel frame formwork, H20 timber beam formwork, aluminum formwork etc.

Our major responsibility is international marketing of different construction machinery & formwork, including lifting machinery, concrete machinery, earthmoving machinery, brick/block machinery; steel frame formwork, H20 timber beam formwork, aluminum formwork etc.

- Q: Which price is low for a pile driver?

- Specializing in sales of steel sheet pile, steel sheet pile construction, leasing, model complete, high quality, the construction of steel sheet pile, the price is more favorable, and exquisite design, honest and trustworthy business purposes, in full accordance with the market-oriented, large-scale, standardized operation requirements specification, through the implementation of brand strategy to build the core competitiveness of enterprises

- Q: How did the pile of clay work after the pile driver finished?

- Friction end bearing pile -- the pile whose load is mainly loaded by the end of pile.Method according to construction methodBored piles: bored piles, immersed tube cast-in-place piles, hand dug bored piles, and explosion enlarged cast-in-place piles.In addition, the hole forming methods are: manual digging, mechanical drilling (positive cycle rotary method, reverse cycle rotary method, auger drilling method, drilling rig drilling method, etc.).

- Q: What's the special use of a pile driver?

- There are two main types of pile driver used at present: diesel hammer pile driver and long spiral drilling rig.In general, long spiral ring power head motor starting current depends on the specific circumstances, if the full voltage starting with load, the starting current is 5-7 times the rated current of the power supply. The construction of their equipment.

- Q: What are the preparations for the piling site?

- 1, the pile position determination: according to the project provided by the construction unit and the pile axis location map of pile location, pile location must be accurate, and in the pile position by a soldering iron drilling, hole depth is 15~20cm, filled with lime, prevent in the process of driving the wrong pile.2. Pile up(1) pile stacking shall be determined by pile driving route and pile driving sequence(2) the site shall be level and level with three passes and one leveling. Remove obstacles in the ground, underground and air in the range of the moving of the pile driver. The wooden posts and the pile rings shall be of the same position, except for the contact between the pile and the pile, and nothing else shall be in contact with the pile so as to prevent cracks in the pile.(3) the strength of reinforced concrete precast piles must be up to 100% before they can be transported and piled3, the selection of pile machineAccording to the design of single pile bearing capacity and pile length, this project intends to use hammer weight 2.5t track type diesel pile driver.

- Q: Requirements of waveform guardrail column piling skills training program and training program.

- B, anti blocking blocks, wave beam, end installation(a) after installing the upright column, the bracket (block block) can be installed. The bracket (stop block) is fixed between the wave beam and the upright post through the connecting bolt. The bracket (block) shall be adjusted to make it in place before tightening the connecting bolts.(b) the wave beam is spliced with each other by a splicing bolt and is fixed by a connecting bolt bracket (an anti blocking block), and the direction of the overlap of the roadbed guardrail and the corrugated beam is the key of the installation, and the installation is carried out in strict accordance with the drawing. The direction of overlap shall be consistent with the driving direction. The wave beam should be adjusted continuously during the installation. Therefore, the connecting bolts and the splicing bolts should not be tightened too early so that the long holes in the corrugated beam can be adjusted in time during the installation process so as to form a smooth alignment and avoid local irregularities. When the alignment of the guardrail is considered satisfactory, the bolt can be screwed at last. The connecting bolt between the bracket (stop block) and the wave beam should not be screwed too tight, so that the temperature stress can be adjusted by using a long round hole.(c) the end beam is spliced with standard section guard bars through splicing bolts. The construction method of the end beam is basically the same as that of the wave beam.

- Q: What is the power of the pile driver?

- Hello, there are many kinds of power in the pile driver. How big do you need?.

- Q: Does the mud come up with the shovel? Can you tamper with a stone? 1.2 traction? How many meters per hour can the ramming mud fall? And the price of the equipment! It's better to have a talk with that big brother! Thank you on your knees

- The main principle that piling machine is generally more vibration hammer (this principle is nothing more than the vibrations make the hydraulic tubing sinking) not used but the price too high maintenance trouble this hour how many meters are not counted nor so counted are generally by 10 meters with a 20 meters as a count this time the specific time depends on the formation of me is to do this to give you about what you do this mainly before entering the first to see money does not receive this is mainly engaged in engineering for the most difficult access fee second third of total output value (and you probably under a mechanical maintenance personnel piling machine is very easy to go wrong) the fourth is the very important geological prospecting (some strata such as large pebbles etc.

- Q: What are the types of hammer pile drivers?

- There are diesel tube pile driver, power source brand, Zhong Zhong brand, and Zhejiang is very popular guide rod hammer

- Q: Such as the title... Phenomenon: quiet with a sound to length, rises again, continuous... Better knowledge about this point for more,...

- This is a hammer driven pile driver that uses diesel fuel to ignite, hammer upward, then drop free, and pile the pile by gravity. Generally used for concrete precast pile and steel pipe pile and so on.

- Q: Why should the pile foundation be excavated after the pile driving?

- If it is high-level, there are first excavation to the bottom of the foundation and then piling

Send your message to us

ZYC series ZYC800B-B multi-functional Hydraulic Static Pile Driver

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 1000 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords