Sheet Pile Driver

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Set set

- Supply Capability:

- 100 Sets per Month set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

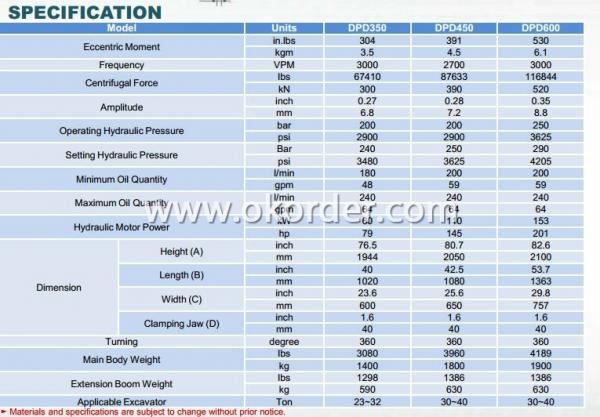

Detailed Product Description of Vibro Ripper, Hammer (Pile Driver)

- 360 degrees rotation of middle bracket

- Proven economic feasibility, mobility, safety

- Driving & Extraction sheet pile, tube, H-beam

- Most representative hydraulic vibro hammer

- Suitable equipment for construction working site

-Excellent performance and mechanisms without power pack.

-Proven workability: With the advantage of the excavator’s mobility, High performance operation at overpasses, under high voltage lines, on bridges and populated cities.

-Maximized the life of the equipment by using a special bearing designed for high frequency

-Best quality of Cushion elastomers are adopted in order to isolate vibration being transmitted to excavator.

-Easy installation using breaker hydraulic line of the excavator with electric cable device and operation control

-Mounting and dismounting can be easily done at all times

-The upper body allows 360 degree free rotation for easy operation and automatically anchors itself during operation

-Sheet pile, H beam and tube can be used by hooking up a wire on the main body of pile driver

-Double clamping devices can be fitted for pipe driving and extracting (Option)

- Q: The grounding of piling machine. Pile machine, three-phase asynchronous motor one day to play 2 piles piling machine and control box are constantly moving, how to ground? And is not a machine box. A gate or a few feet to ground is the five core. In three, the rest of the root, the zero line and the PE are useless? Thank you, predecessors, great God under the guidance of? In this way, the master said that the reception will be over, installed a leak protection, is not installed, the leak insurance does not need to ground ah?

- Five core power cable, PE core wire may reach 16 square, in pile machine within 30 meters hit a 3 meter long galvanized angle (angle 50X5X3000), the head of a hole on the M10 (or M12) galvanized bolts, connecting 16 square BVR yellow green color line to the pile machine (repeat grounding), angle head (to prevent the hammer head welding deformation angle) a piece of iron, if you want to reuse (pull out in place again), can be connected with the hanging wire rope or a hook hole in angle steel.

- Q: say no money, the machine is more expensive, but still busy every day do not win, do not know is true or false?

- Certainly money ah, now people are selfish, just want to make money, Matlock machine good, I also encountered such a thing.

- Q: What's the model of a portable anti flood pile driver? What is the depth of the pile?

- Total mass of power plant: 73KgOverall size: * * width * height 660*500*750mm2) host:Structure: shock, shock, frequency modulationMaximum impact energy: 110.46N..MHost weight: 74KgFlexible shaft length: 4m

- Q: Which manufacturer is better for highway guardrail and pile driver?

- There are many manufacturers of pile drivers now. Do you buy them online or offline?

- Q: What is the power of the pile driver?

- We produce crawler pile driving machines with a power of 57KW.

- Q: now to pull out, how can pull out? FiveThe machine can not be used, how to take out in a simple way! Now, how many tons of jacks do I need if I use a jack?

- Is it possible to use a vibratory hammer, or a hydraulic high frequency vibrator?.

- Q: What are the parts of a pile driver?

- The two guiding rods are omitted, and the plunger is a hammer head, which can move up and down in the cylinder. When piling, the pile cap at the bottom of the hammer block is pressed on the top of the pile, lifting the plunger with a hook, and then decoupling and downward impacting to compress the air enclosed in the cylinder. And fuel injection, explosion, shock, ventilation and other work processes. Diesel hammer work is on compression ignition diesel to start, it is necessary to ensure the closed gas cylinder reaches a certain compression ratio, sometimes piling in soft soil layer is often because the reaction is too small, the amount of compression is not sufficient to ignite the ignition, it needs to use the hook to lift a hammer from multiple impact, to start. The hammer seat of the diesel hammer is provided with a fuel injection pump, an oil tank, a cooling water tank and a pile cap. The movable gap between the plunger and the cylinder is sealed with an elastic plunger ring. Four, hydraulic hammer piling machine is a diesel belt start, to the oil pressure as the driving force, can be adjusted according to the formation of different soil pressure, in order to achieve the appropriate impact force for piling, is a new type of pile driver. Small and medium-sized hydraulic pile driver, commonly used in highway guardrail piling, highway guardrail construction. Similar pile driving equipment are: hydraulic pile driver, road pile driver, guardrail, pile driver, road drilling machine.

- Q: How many small pile drivers are there in Hunan? It's best to have the exact location

- Hunan small piling machine manufacturers or a lot, like Hunan wylong machinery should be more excellent in mechanical industry.

- Q: What pile driving machine should be used for the 400*400 square pile?

- When in operation, the pile hanging in place pile frame in Longmen, then put the diesel hammer at the top of the pile, the hook will lift down the cylinder, and the cylinder sleeve off hook to the whereabouts of the piston, the cylinder will be closed in the air compression cylinder rocker pin until the pressure continues to fall outside the cylinder pushing hammer on the base of the fuel pump, fuel pump will be injected into the cylinder oil mist, oil mist meet high temperature gas burning immediately above, blasting, explosive shock down pile., to push the cylinder to cylinder to rise, fall along the guide rod, and the beginning of the second impact cycle.

- Q: Do you make money on building pile drivers? How long will it take to recover the cost?

- Can make money, in the case of business, half a year time will be able to recover costs!

1. Manufacturer Overview

| Location | South Korea |

| Year Established | 1982 |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | Certificate of conformity with the following European Directives;ISO 9001:2008 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b) Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Sheet Pile Driver

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Set set

- Supply Capability:

- 100 Sets per Month set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords