Z profile Sheet Pile WRZ

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of Z profile Sheet Pile WRZ:

Type | Width | Height | Thickness | Sectional area | Weight per pile | Weight per wall | Moment of Inertia | Modulus of section |

| mm | mm | mm | Cm2/m | Kg/m | Kg/ m2 | Cm4/m | Cm3/m |

WRZ5-850 | 850 | 253 | 5 | 61.2 | 40.8 | 48.0 | 6416 | 507 |

WRZ6-850 | 850 | 254 | 6 | 73.2 | 48.9 | 57.5 | 7671 | 604 |

WRZ10-700 | 700 | 350 | 5 | 75.9 | 41.7 | 59.6 | 17208 | 983 |

WRZ12-650 | 650 | 319 | 7 | 113.2 | 57.8 | 88.9 | 19603 | 1229 |

WRZ14-650 | 650 | 320 | 8 | 128.9 | 65.8 | 101.2 | 22312 | 1395 |

WRZ16-635 | 635 | 379 | 7 | 122.5 | 61 | 96.1 | 30502 | 1610 |

WRZ18-635 | 635 | 380 | 8 | 139.6 | 69.6 | 109.6 | 34717 | 1827 |

WRZ18A-685 | 685 | 401 | 9 | 142.8 | 76.8 | 112.1 | 37335 | 1862 |

WRZ20-685 | 685 | 402 | 10 | 158.4 | 158.4 | 158.4 | 158.4 | 158.4 |

WRZ22-635 | 635 | 417 | 9 | 162.6 | 81 | 127.6 | 47225 | 2265 |

WRZ25-635(平) | 635 | 418 | 10 | 179.5 | 89.5 | 141 | 52258 | 2500 |

WRZ25-635(弯) | 635 | 418 | 10 | 189.3 | 94.4 | 148.6 | 52258 | 2500 |

WRZ28-635 | 635 | 419 | 11 | 207.9 | 103.6 | 163.2 | 58786 | 2806 |

WRZ30-635 | 635 | 420 | 12 | 226.2 | 112.8 | 177.5 | 63889 | 3042 |

WRZ30-700 | 700 | 449 | 11 | 202.9 | 111.5 | 159.3 | 67025 | 2986 |

WRZ32-635 | 635 | 421 | 13 | 245.4 | 122.3 | 192.7 | 68954 | 3276 |

WRZ34-675 | 675 | 490 | 12 | 222.2 | 117.8 | 174.4 | 84657 | 3455 |

WRZ37-675 | 675 | 491 | 13 | 242.3 | 128.4 | 190.2 | 91327 | 3720 |

WRZ38-675 | 675 | 491.5 | 13.5 | 249.6 | 132.3 | 196 | 94699 | 3853 |

WRZ40-675 | 675 | 492 | 14 | 258.4 | 136.9 | 202.9 | 98065 | 3984 |

WRZ47-700 | 700 | 549 | 14 | 269 | 147.8 | 211.2 | 129356 | 4712 |

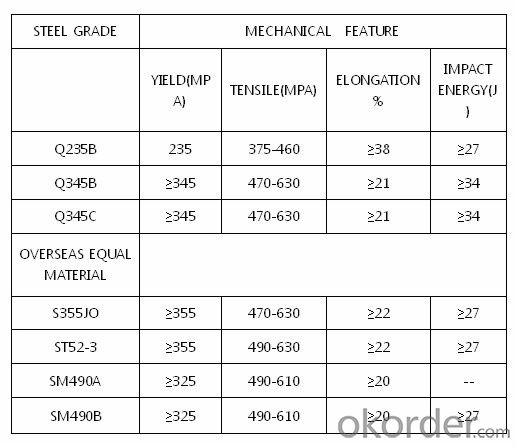

Steel Grade for Sheet Pile

Usage and Applications of Z profile Sheet Pile WRZ:

1. Used for the permanent constructional structure such as embankment, harbors, docks, retaining walls, anti-earthquake reinforcement project, flood gates, etc

2. used for the provisional structure to seal the mountain, provisionally to retain the wall, to cut off the river, to cofferdam, to lay the pipeline and to ward off the earth, the water or the sand

3. Used for the flood-fighting and emergency rescues to prevent the flood, collapse, sink or sediment flow, etc.

Advantage of Z profile Sheet Pile WRZ:

Ø Excellent properties with high tensile strength

Ø Capable of saving steels economically

Ø Extremely competitive section modulus

Ø High installation performance with large width

- Q: How is steel produced?

- Steel is produced through a process called steelmaking, which typically involves the combination of iron ore, coal, and limestone in a blast furnace. The iron ore is first mined and then refined into iron through a series of heating and cooling processes. The refined iron is then combined with coal and limestone in the blast furnace, where it is heated to extreme temperatures to remove impurities and convert it into molten iron. This molten iron is then further processed to remove any remaining impurities and adjust its carbon content to create different grades of steel.

- Q: How is steel wire rope used in elevators?

- Steel wire rope is used in elevators to provide the necessary strength and support for lifting heavy loads. It is typically used as the main hoisting cable, ensuring smooth and safe vertical movement of the elevator car. The steel wire rope is highly durable and can withstand the constant stress and tension experienced during elevator operation, making it an essential component in ensuring the reliability and safety of elevators.

- Q: What are the different types of steel fasteners and their uses in the aerospace industry?

- There are several different types of steel fasteners commonly used in the aerospace industry, including bolts, screws, nuts, and rivets. These fasteners are essential for joining various components and structures in aircraft manufacturing and maintenance. Bolts are typically used to secure heavy loads and provide strong connections, while screws are used for lighter applications. Nuts are used in conjunction with bolts to create a threaded connection. Rivets, on the other hand, are used to permanently join materials together by deforming the fastener upon installation. Each type of steel fastener has its specific uses and strengths, contributing to the overall safety and reliability of aerospace structures.

- Q: How do steel products contribute to the mining and excavation industry?

- Steel products play a crucial role in the mining and excavation industry by providing essential equipment and infrastructure. From drill bits and cutting tools to conveyor belts and structural support systems, steel products are used extensively in various mining operations. The strength, durability, and resistance to corrosion of steel make it ideal for withstanding the demanding conditions encountered in mines and excavation sites. Additionally, steel is also used to manufacture machinery and vehicles needed for mining activities, such as excavators, bulldozers, and trucks. Overall, steel products are essential for the efficiency and safety of mining and excavation operations.

- Q: What are the uses of steel wire mesh?

- Steel wire mesh has a wide range of uses in various industries and applications. It is commonly used in construction for reinforcing concrete structures, such as roadways, bridges, and buildings. Steel wire mesh is also used in fencing and security applications to create strong and durable barriers. In the agriculture sector, it is used for animal enclosures, bird cages, and plant support structures. Additionally, steel wire mesh is utilized in filtration systems, sieving and sorting processes, and as a decorative element in architectural designs.

- Q: What are the common uses of steel pipes and tubes?

- Steel pipes and tubes are commonly used in various industries and applications. They are extensively used for transporting fluids and gases, such as water, oil, and natural gas, in plumbing and gas distribution systems. Additionally, steel pipes and tubes are essential in construction projects for structural support, including building frames, bridges, and scaffolding. They are also used in the automotive industry for manufacturing exhaust systems and chassis components. Furthermore, steel pipes and tubes find applications in the manufacturing of furniture, appliances, and agricultural equipment. Overall, their durability, strength, and versatility make steel pipes and tubes indispensable in a wide range of sectors.

- Q: What are the challenges faced in the welding of steel products?

- There are several challenges faced in the welding of steel products. One of the main challenges is the potential for distortion or warping of the steel during the welding process. Steel has a high thermal conductivity, which means it can quickly absorb and distribute heat. This can lead to uneven heating and cooling, causing the metal to deform. Another challenge is the presence of impurities and contaminants on the surface of the steel, such as rust, oil, or paint. These impurities can negatively affect the quality of the weld and make it more difficult to achieve proper fusion. Additionally, the high carbon content in some types of steel can make it more prone to cracking and brittleness during the welding process. Proper pre-cleaning, selection of appropriate welding techniques, and careful control of heat input are crucial in overcoming these challenges and producing high-quality welded steel products.

- Q: What are the different types of steel sheet and plate materials?

- There are several types of steel sheet and plate materials, including carbon steel, alloy steel, stainless steel, and galvanized steel.

- Q: What are the advantages of using steel in the manufacturing of tanks and vessels?

- There are several advantages of using steel in the manufacturing of tanks and vessels. Firstly, steel is known for its exceptional strength and durability, making it highly resistant to corrosion and damage from external factors. This ensures the longevity of tanks and vessels, reducing the need for frequent repairs or replacements. Additionally, steel's high tensile strength allows for the construction of tanks and vessels with thinner walls, maximizing storage capacity while maintaining structural integrity. Moreover, steel is a versatile material that can be easily formed into various shapes and sizes, allowing for customization and efficient use of space. Lastly, steel is a cost-effective option due to its availability, recyclability, and low maintenance requirements, making it a preferred choice for the manufacturing of tanks and vessels.

- Q: What are the different types of steel bridges and structures available?

- There are several types of steel bridges and structures available, including truss bridges, arch bridges, suspension bridges, cable-stayed bridges, and beam bridges. Truss bridges feature a framework of connected triangular elements, while arch bridges have a curved design that carries the load through compression. Suspension bridges are supported by cables hung from tall towers, and cable-stayed bridges have cables attached directly to the supporting towers. Beam bridges are the simplest type, consisting of beams supported by piers or abutments. These various designs offer different advantages and are chosen based on factors such as span length, site conditions, and aesthetic preferences.

Send your message to us

Z profile Sheet Pile WRZ

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords