L/S profile Steel Sheet Pile WRL WRS

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of L/S profile Steel Sheet Pile WRL WRS:

L Profile sheet piles

Profile

| Dimension | Mass | Moment of Inertia | Elastic section Modulus | |||

Width B | Height H | Thickness T | Per Pile

| Per wall

| |||

| mm | mm | mm | Kg/m | Kg/ m2 | Cm4/m | Cm3/m |

WRL1.5 | 700 | 100 | 3.0 | 21.4 | 30.6 | 724 | 145 |

WRL2 | 700 | 150 | 3.0 | 22.9 | 32.7 | 1674 | 223 |

WRl3 | 700 | 150 | 4.5 | 35.0 | 50.0 | 2469 | 329 |

WRL4 | 700 | 180 | 5.0 | 40.4 | 57.7 | 3979 | 442 |

WRL5 | 700 | 180 | 6.5 | 52.7 | 75.3 | 5094 | 566 |

WRL6 | 700 | 180 | 7.0 | 57.1 | 81.6 | 5458 | 606 |

S Profile sheet piles

Profile

| Dimension | Mass | Moment of Inertia | Elastic section Modulus | |||

Width B | Height H | Thickness T | Per Pile

| Per wall

| |||

| mm | mm | mm | Kg/m | Kg/ m2 | Cm4/m | Cm3/m |

WRS4 | 600 | 260 | 3.5 | 31.2 | 41.7 | 5528 | 425 |

WRS5 | 600 | 260 | 4.0 | 36.6 | 48.8 | 6703 | 516 |

WRS6 | 700 | 260 | 5.0 | 45.3 | 57.7 | 7899 | 608 |

WRS8 | 700 | 320 | 5.5 | 53.0 | 70.7 | 12987 | 812 |

WRS9 | 700 | 320 | 6.5 | 62.6 | 83.4 | 15225 | 952 |

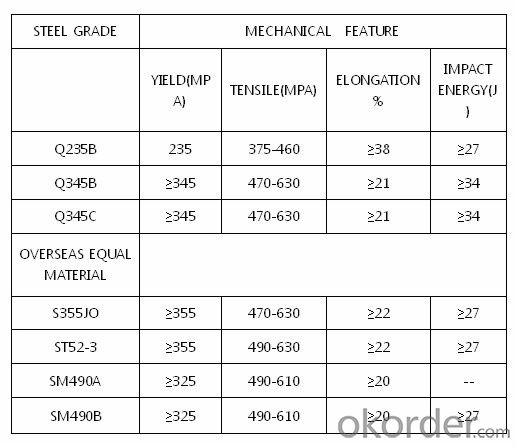

Steel Grade for Sheet Pile

Usage and Applications of L/S profile Steel Sheet Pile WRL WRS:

1. Used for the permanent constructional structure such as embankment, harbors, docks, retaining walls, anti-earthquake reinforcement project, flood gates, etc

2. used for the provisional structure to seal the mountain, provisionally to retain the wall, to cut off the river, to cofferdam, to lay the pipeline and to ward off the earth, the water or the sand

3. Used for the flood-fighting and emergency rescues to prevent the flood, collapse, sink or sediment flow, etc.

- Q: How do steel products contribute to the construction of theme-based amusement parks?

- Steel products play a crucial role in the construction of theme-based amusement parks. From roller coasters and thrill rides to elaborate structures and supports, steel provides the strength, durability, and flexibility required for these complex and dynamic attractions. The use of steel allows for innovative and imaginative designs, enabling architects and engineers to create towering structures, intricate frameworks, and exhilarating rides that captivate visitors and enhance the overall experience of the park. Steel products also ensure the safety of the park, as they can withstand heavy loads, extreme weather conditions, and intense use, providing a reliable and secure environment for park-goers. In summary, steel products are indispensable in building theme-based amusement parks, contributing to their unique and awe-inspiring attractions.

- Q: What are the different types of steel bars?

- There are several different types of steel bars, including mild steel bars, deformed steel bars, high tensile steel bars, stainless steel bars, and alloy steel bars. Each type of steel bar has its own unique properties and uses in various industries and applications.

- Q: What are the uses of steel wire mesh in agriculture?

- Steel wire mesh is commonly used in agriculture for various purposes. It is used as fencing material to create boundaries and protect crops from animals or pests. Steel wire mesh is also used as trellises or support structures for climbing plants, such as tomatoes or beans. Additionally, it can be used to create cages or enclosures for livestock or poultry, providing them with a safe and secure environment. The durability and strength of steel wire mesh make it an ideal material for these applications in agriculture.

- Q: What is the role of steel in the manufacturing of railway tracks?

- Steel plays a crucial role in the manufacturing of railway tracks as it is the primary material used for the rails. Steel's high strength, durability, and resistance to wear and deformation make it ideal for withstanding heavy loads, extreme weather conditions, and continuous train traffic. The use of steel ensures the tracks remain stable, safe, and capable of supporting the weight of trains over long distances, contributing to the efficiency and reliability of the railway system.

- Q: What are the common types of steel products used in the agricultural industry?

- Some common types of steel products used in the agricultural industry include fencing materials, gates, barn structures, agricultural machinery and equipment, irrigation systems, storage tanks, and trailers.

- Q: What are the different types of steel gratings and their applications?

- There are several types of steel gratings, including welded steel grating, press-locked steel grating, and riveted steel grating. Welded steel grating is commonly used for industrial flooring, catwalks, and stair treads due to its durability and strength. Press-locked steel grating is often used for architectural and decorative purposes, such as walkways, platforms, and sunscreens. Riveted steel grating is suitable for heavy-duty applications such as bridge decking, truck platforms, and loading docks.

- Q: How is steel used in the construction of sports stadiums and arenas?

- Steel is commonly used in the construction of sports stadiums and arenas due to its strength and durability. It is used to create the framework and support structures, such as columns, beams, and trusses, which provide stability and withstand heavy loads. Steel is also utilized in roofing systems, grandstands, and seating sections, ensuring the safety of spectators. Overall, steel plays a crucial role in creating the robust and spacious structures required for hosting large-scale sporting events.

- Q: How is steel used in the production of musical instruments?

- Steel is commonly used in the production of musical instruments due to its strength, durability, and ability to produce a clear and resonant sound. It is typically used for strings, such as guitar and piano strings, as well as for the construction of various percussion instruments like drums and cymbals. Additionally, steel is often used in the manufacturing of certain wind instruments, such as saxophones and trumpets, where its malleability allows for precise shaping and tuning of the instrument.

- Q: What are the different types of steel fasteners and connectors available?

- There are several types of steel fasteners and connectors available, including screws, bolts, nuts, washers, anchors, rivets, and clips. Each type has its own specific application and is designed to provide secure and reliable connections in various construction and manufacturing industries.

- Q: How is steel tubing used in hydraulic systems?

- Steel tubing is commonly used in hydraulic systems to transmit fluid power by providing a rigid and reliable conduit for the hydraulic fluid. It is used to connect various components in the system, such as pumps, valves, cylinders, and motors, ensuring efficient transfer of hydraulic energy. Steel tubing's high strength, durability, and resistance to pressure and impact make it ideal for handling the high pressures and demanding operating conditions of hydraulic systems.

Send your message to us

L/S profile Steel Sheet Pile WRL WRS

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords