ZYC series ZYC700B-B multi-functional Hydraulic Static Pile Driver

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 1000 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

ZYC series multi-functional Hydraulic Static Pile Driver

Features:

Main product: ZYC series multi-functional Hydraulic Static Pile Driver Self-developed with 5 up-to-date patents.

The working principle is using hydraulic pressure to clamp precasted pile, H shape or other shape steel pile, and then driving the pile into ground by hydraulic pressing.

Suitable for piling precast round & square concrete pile, H shape steel pile and other irregular-shaped pile in clay, soft soil and sandy ground.

It has characteristics of no noise, no vibration, no pollution, clear ground with high speed of pile driving, reliable construction quality and environmental protection, high efficiency, energy saving. It is welcomed by the customers with wide market prospect.

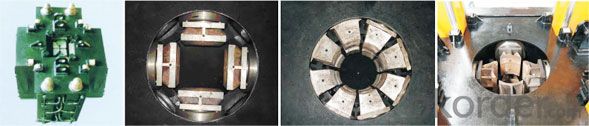

● Multi-functional piling technology

Original combination clamping piling and top piling won invention patent

● Flexible connection technology

Novel flexible connection technology of central axis, won national practical patent

● Integrative side and corner piling technology

Particular side and corner piling mechanism increasing the capability of side & corner piling and won national practical patent

● Inverted cylingder technology

Structure design of inverted cylinder changes strained condition of cylinder and increases the service life of cylinder, won national practical patent

Self-adaptive clamping mechanism

Original self-adaptive clamping mechanism won national practical patent

Parameters:

| Rated piling pressure(tf) | 700 | suitable pile & specification(mm) | ¢300-800 | |

| Max. Piling speed(m/min) | 5.9 | Max. Crane lifting weight(t) | 16 | |

| Piling stroke(m) | 2.0 | Hanging pile length(m) | 15 | |

| Max. Longitudinal pace(m) | 3.6 | Minimum side piling space(mm) | 1380 | |

| Max. Transverse pace(m) | 0.6 | Minimum corner piling space(mm) | 2800 | |

| Max. Rise stroke(m) | 1.1 | Intensity of pressure(tf/m²) | 14.2/19.4 | |

| Max.rotation angle per time(°) | 11 | Weight composition | (t) Machine weight | 186±3 |

| Rated hydraulic system pressure(mpa) | 25(20) | Added water weight(t) | 48 | |

| Hydraulic Pump (Unit × Ml/Turn) | 3×80 + 1×80 | Counter weight(t) | 466 | |

| Motor power (Unit × kw) | 3×37 + 1×30 | Total weight(t) ≥ | 700 | |

FAQ

1.To provide customers with professional and technical services, to meet the demands of customers for construction efficiency and cost control, to achieve value for customers, which is the constant pursuit of Toppile, Toppile implant this concept in the whole process of sales and services.

Before sales

Research market with customers; provide technical advice, customized design and production.

2. On sales

Always communicate and adjust of design with customer to ensure the product satisfy all requirements.

3. After sales

Provide installation, adjustment, maintenance service, create customers files, following up machine working situation, provide customer a whole set of “Butler” and “Gapless”services.

4. Value added services

Redesign and upgrade the hydraulic system of piling machine, upgrade structure components.

Provide high quality and lower price components.

Toppile is the agent of many components factories, including cylinders, pumps, seals, hydraulic elements.

- Q: In what type of terrain can the survival machine be used to strike minerals?

- Any terrain. As long as you dare to go down

- Q: The working principle of a pile driver ship

- The piling ship is equipped with a pile hammer, a pile stand, and auxiliary equipment.

- Q: What kind of pile driver, rotary drilling machine can drill under medium weathering rock layer?

- The Xugong power head, wylong machinery mechanical lock rod rotary drilling rig Yuchai engine and can be weathered rock and sediment layer in the layer below, backfill soil drilling construction

- Q: Why should I pull it up a few times? Because the friction should stop gradually

- This problem is very simple, you just don't know it. The working principle of diesel hammer, hammer force pull up several times in the ignition, ignition after diesel combustion explosive can put the hammer from the top, the hammer reaches a certain height to fall under gravity, in the moment of contact pressure the light diesel (compression diesel can make its combustion is its characteristics), and was the top hammer, again and again.

- Q: How many prestressed concrete pipe piles can a pile driver hit in a day?

- You can hit 4 roots a day.Precast pile, various materials, various forms made in the factory or the construction site of the pile (such as wood, concrete pile, prestressed concrete pipe pile, steel, etc.) with piling equipment will be pressed into piles, or buried in vibration. More prefabricated piles are used in the field of building construction in China, mainly concrete precast piles and steel piles in two major categories.Precast piles are mainly concrete precast pile and steel pile two major categories. Precast concrete pile can bear larger load, durable, fast construction speed, is one of the most widely used type of pile, but its construction has great influence on the surrounding environment, are the most commonly used concrete solid pile and prestressed concrete hollow pile. Steel pile is mainly steel pipe pile and H steel pile two kinds.

- Q: How many hydraulic pile drivers or diesel pile drivers are used in high-rise residential buildings?

- The pile foundation of high-rise building usually adopts precast pipe pile and seldom uses cast-in-place pile.

- Q: Should the starting current be considered when the piling machine is in use?

- There are two main types of pile driver used at present: diesel hammer pile driver and long spiral drilling rig.In general, long spiral ring power head motor starting current depends on the specific circumstances, if the full voltage starting with load, the starting current is 5-7 times the rated current of the power supply. The construction of their equipment. In addition to see how much power head in the face of tricyclic sticking case, two start if exceeds the rated current of it easily after all, a burning motor, power head is not cheap, suggest to consider all hydraulic power head, the power head is three was a bit expensive, but in the face of the card when drilling, two times can start easily and smoothly, the impact of the power grid is very small. Moreover, the torque of the hydraulic power head is 2-3 times as much as that of the ordinary three ring power head. It is more suitable for complex formation than the traditional long spiral, and the construction efficiency is more efficient. Long spiral drill in the type piling machine is the use of a more extensive, and for starting current understanding, we can get better in the construction layout, so as to avoid the occurrence of the voltage is not enough at the time of construction.

- Q: What are the types of hammer pile drivers?

- There are diesel tube pile driver, power source brand, Zhong Zhong brand, and Zhejiang is very popular guide rod hammer

- Q: CFG pile 22 meters deep, please tell me how many piles are required to flow out at the side of the slope. How about the 360 degree rotation of the pile driver?

- General 50-80, the best drill pipe can be connected, but the construction capacity of pile driver is limited, generally there are more than 20 meters, more than thirty meters, high rack will be able to play deeper.

- Q: How can I find a pile driver?

- Go to the construction site, it is better to have known the construction team, or the construction company pull!

Send your message to us

ZYC series ZYC700B-B multi-functional Hydraulic Static Pile Driver

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 1000 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords