KLB26-800 Bored Pile Drilling Rig for Sale

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 1000 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

KLB20-600 Bored Pile Drilling Rig for Sale

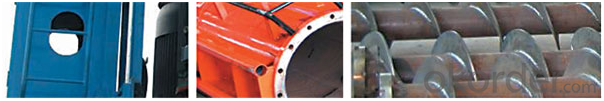

Product Features:

A Wide Choice Of Product: |

>>Our company is capable to manufacture various types of KL series drilling rigs. The max drilling depth could reach 20m to 34m.A wild range of products could be chosen for your practical needs. |

|

The column of the piling frame has two types, square and round. The former type applies back lift method. It is easily installed, safe and stable. The later type applies front lift method, the support rod will adjust itself when lifting the column. The column is higher, the drilling depth will go deeper. |

|

Higher Efficiency And Lower Consumption: |

>>The hydraulic system uses constant power variable design with low loss.The large flow, low failure rate, and high efficiency piston pump ensures the hydraulic components working well. |

|

high Reliability And Flexibility: |

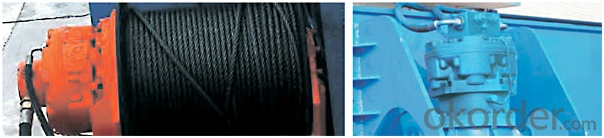

>>The rotation system works with hydraulic flow. The rotating speed could be controlled to avoid impact. The failure rate is much reduced. The assistant hoist also uses hydraulic winch so the winding speed can be controlled at the operator’s will. Such design provides much convenience in the working process. |

|

Convenience In Dismantling, Transportation And Maintenance: |

>>With many years improvement and seeking for perfection, each part of the machine has well considered its convenience in dismantling, transportation and maintenance. The height and width of the largest part is designed within the range of transportatio lmits. |

|

Humanized Design: |

>>Much effort has been taken to increase the technical content on our products as well as humanized design. The machine is integrated with mechanical, electrical, hydraulic, and electronic devices. The appearance of the machine body, the comfort of the operator, the agility of the movements and so on are all well considered when designing the machine.Remote-control handle is optional due to the client's needs. |

|

Unique Design: |

>>After many years of experience in manufacturing the machine and analyzing feedbacks from our loyal clients, we made unique improvements in the easy-malfunction parts on the drilling rig: The bottom pillar of the column uses universal joint to enable the pole adjusted from left-right and front-back directions. The side support adjustment mechanism uses hydraulic motor instead of electrical motor which may affect the adjustment stroke or worm and gear which may shorten the life period. The supporting leg cylinder base uses large round box structure to avoid distortion at the working process. |

|

Multi-function: |

>>KL series is our new generation multi- function piling frame: with different power plant it can not only be used to do bored pile drilling or construct continuous wall by SMW method, but also do diesel hammer or hydraulic hammer pile driving. |

|

| KLB26-800 | ||

|---|---|---|

| Move method | Electro-hydraulic step | |

| Max drilling depth | 26m | |

| Max drilling diameter | φ800 | |

| Max output torque | 48.5KN·m | |

| Rod rotated speed | 23r/min | |

| Allowed lifting force | 400KN | |

| Power for power head | 55KWX2 | |

| Reductor of power head | ZZSH480 | |

| Leader size | φ630X8 | |

| Leader height | 31m | |

| Leader oriented center distance | 600Xφ102 | |

| Leader incline range | 5°front inclination 3°back inclination | |

| Stroke | 1.5m | |

| Climbing ability | <6° | |

| Rotary | Rotary way | Rotary motor |

| Rotary angle | ≤360° | |

| Rotary speed | 0~0.3 | |

| Main winch | Single pulling force | 5T |

| Increasing speed | 2.0/2.6/3.2 | |

| Motor power | 22KW | |

| Assist winch | Single pulling force | 2T |

| Increasing speed | 20m/min | |

| Motor power | 7.5KW | |

| Overall dimension(L*W) | 10m×5.2m | |

| Total weight(T) | 63T | |

FAQ

1.Which payment terms can we accept?

Normally we can work on T/T term or L/C.If you choose T/T,30% payment is required in advance and 70% balance shall be settled before shipment often,it rang a little.

2.How long will our price be valid?

We are friendly dealer, never greedy windfall profit, our price remains stable,except the exchange rate and the increasing labor cost and material cost.

3.What are our advantages compared with manufacturers?

a.Detailed training-We can provide training services to different users. The training sessions include product training,operating training, maintenance know-how,standard and so on to fulfill your individual needs.The training can be conducted at client’s site.

b.Available after service-With our global distributor network, you are guaranteed with fast deliveries and services if you submit your requests.

- Q: Multilayer, six layers! Real Estate Company real estate. I would like to ask you to build the foundation is a good pile or independent column good? May I have some questions from insiders?! Thank you

- Depends on geological reports, can not pile, it is best to save a lot of money Oh!

- Q: The ground site must be driven by a pile driver

- The main aspect is related to the structural characteristics, height and load of the proposed building, and the other major aspects are geological conditions, such as formation, geotechnical properties, strength, distribution, depth of burial, etc..The foundation has shallow foundation and pile foundation, and the foundation is divided into natural foundation and foundation to deal with the artificial foundation.Even if your building needs to use a pile foundation, "piling" also has many ways, including drilling, immersed pipes, prefabricated, spiral, digging holes

- Q: What is an impact pile driver?

- You mean the kind of pile driver that used to use high explosive diesel engines to produce impact?The principle is like using the percussion hammer nails, using a hammer impact in the nail head will generate the nail.It's very seldom used now.

- Q: What's the special use of a pile driver?

- Moreover, the torque of the hydraulic power head is 2-3 times as much as that of the ordinary three ring power head. It is more suitable for complex formation than the traditional long spiral, and the construction efficiency is more efficient. Long spiral drill in the type piling machine is the use of a more extensive, and for starting current understanding, we can get better in the construction layout, so as to avoid the occurrence of the voltage is not enough at the time of construction.

- Q: What's the model of a portable anti flood pile driver? What is the depth of the pile?

- Shape size * height * width 450*350*450mm3) work parameters:Operation object: River, Hutang embankment (homogeneous soil)Pile diameter: 60 - 120mmLength: less than or equal to 3000mmPile driving speed: 500-1000mm/minIf you don't know, you can ask me again

- Q: Pile driver model, which brand is better?

- As for the piling machine brand small piling machine is recommended a Matlock in Hunan, the drilling machine is widely used in city high-rise buildings, railways, highways, bridges, airports, ports and other pile foundation engineering irrigation pile construction, has wide application range, high construction efficiency, stable performance, and thoughtful service, environmental protection and energy saving the advantages of.

- Q: I have a pile machine construction record card, but Supervision said or not, please master pointing.

- If there is any nonconformity, the rectification shall be completed and checked by the supervision.

- Q: Which brand is good for a pile driver / pile driver?

- Pile driver has multiple types of wheeled and tracked, allowing users to have more choices, but in terms of pricing is reasonable, domestic brands in the relatively high cost of sales in the top brands, many brands.

- Q: What's the difference between a pile driver and a boring pile driver?

- Piling machine generally refers to prefabricated prefabricated pile hoisting, with heavy hammer into the underground or static pressure into the underground machinery. The bored pile machine is the first hole, the next steel cage, and then pouring concrete machinery.The difference is that the pile in the construction of the pile driver is prefabricated.The bored pile machine is a cast-in-place pile on the spot

- Q: How many types of piles are there in the site? What procedures are usually used for piling? Such as eyes open what kind of..

- (3) screw in pile;The screw in pile is a spiral plate at the end of the pile, which is gradually transferred into the foundation by the torsion of the external machinery. The cross section of the pile is generally small, but the spiral plate is relatively large, and the disturbance of the pile side soil is larger during the construction of the spiral pile, so the screw plate of the pile head bears the axial pressure or tensile force of the pile.(4) vibration sinking pile;The vibration sinking pile is the vibrating sinking pile, and the precast pile is sunk into the ground by the vibration and vibration action of the vibrating pile driving machine. This method of construction is basically between the method of penetration and the method of pressing in.

Send your message to us

KLB26-800 Bored Pile Drilling Rig for Sale

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 1000 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords