KLB32-800 Bored Pile Drilling Rig for Sale

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 1000 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

KLB20-600 Bored Pile Drilling Rig for Sale

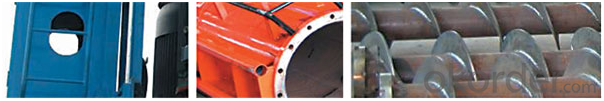

Product Features:

A Wide Choice Of Product: |

>>Our company is capable to manufacture various types of KL series drilling rigs. The max drilling depth could reach 20m to 34m.A wild range of products could be chosen for your practical needs. |

|

The column of the piling frame has two types, square and round. The former type applies back lift method. It is easily installed, safe and stable. The later type applies front lift method, the support rod will adjust itself when lifting the column. The column is higher, the drilling depth will go deeper. |

|

Higher Efficiency And Lower Consumption: |

>>The hydraulic system uses constant power variable design with low loss.The large flow, low failure rate, and high efficiency piston pump ensures the hydraulic components working well. |

|

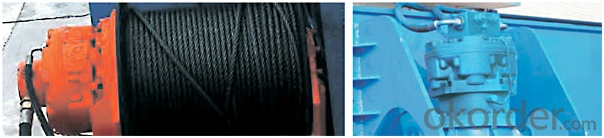

high Reliability And Flexibility: |

>>The rotation system works with hydraulic flow. The rotating speed could be controlled to avoid impact. The failure rate is much reduced. The assistant hoist also uses hydraulic winch so the winding speed can be controlled at the operator’s will. Such design provides much convenience in the working process. |

|

Convenience In Dismantling, Transportation And Maintenance: |

>>With many years improvement and seeking for perfection, each part of the machine has well considered its convenience in dismantling, transportation and maintenance. The height and width of the largest part is designed within the range of transportatio lmits. |

|

Humanized Design: |

>>Much effort has been taken to increase the technical content on our products as well as humanized design. The machine is integrated with mechanical, electrical, hydraulic, and electronic devices. The appearance of the machine body, the comfort of the operator, the agility of the movements and so on are all well considered when designing the machine.Remote-control handle is optional due to the client's needs. |

|

Unique Design: |

>>After many years of experience in manufacturing the machine and analyzing feedbacks from our loyal clients, we made unique improvements in the easy-malfunction parts on the drilling rig: The bottom pillar of the column uses universal joint to enable the pole adjusted from left-right and front-back directions. The side support adjustment mechanism uses hydraulic motor instead of electrical motor which may affect the adjustment stroke or worm and gear which may shorten the life period. The supporting leg cylinder base uses large round box structure to avoid distortion at the working process. |

|

Multi-function: |

>>KL series is our new generation multi- function piling frame: with different power plant it can not only be used to do bored pile drilling or construct continuous wall by SMW method, but also do diesel hammer or hydraulic hammer pile driving. |

|

| KLB32-800 | ||

|---|---|---|

| Move method | Electro-hydraulic step | |

| Max drilling depth | 32m | |

| Max drilling diameter | φ800 | |

| Max output torque | 65KN·m | |

| Rod rotated speed | 18r/min | |

| Allowed lifting force | 640KN | |

| Power for power head | 55KWX2 | |

| Reductor of power head | ZZSH480 | |

| Leader size | φ630X10 | |

| Leader height | 37m | |

| Leader oriented center distance | 600Xφ102 | |

| Leader incline range | 5°front inclination 3°back inclination | |

| Stroke | 1.8m | |

| Climbing ability | <6° | |

| Rotary | Rotary way | Rotary motor |

| Rotary angle | ≤360° | |

| Rotary speed | 0~0.3 | |

| Main winch | Single pulling force | 7T |

| Increasing speed | 1.8/2.2/2.6 | |

| Motor power | 22KW | |

| Assist winch | Single pulling force | 3T |

| Increasing speed | 20m/min | |

| Motor power | 11KW | |

| Overall dimension(L*W) | 11.5m×6m | |

| Total weight(T) | 78T | |

FAQ

1.Which payment terms can we accept?

Normally we can work on T/T term or L/C.If you choose T/T,30% payment is required in advance and 70% balance shall be settled before shipment often,it rang a little.

2.How long will our price be valid?

We are friendly dealer, never greedy windfall profit, our price remains stable,except the exchange rate and the increasing labor cost and material cost.

3.What are our advantages compared with manufacturers?

a.Detailed training-We can provide training services to different users. The training sessions include product training,operating training, maintenance know-how,standard and so on to fulfill your individual needs.The training can be conducted at client’s site.

b.Available after service-With our global distributor network, you are guaranteed with fast deliveries and services if you submit your requests.

- Q: Multilayer, six layers! Real Estate Company real estate. I would like to ask you to build the foundation is a good pile or independent column good? May I have some questions from insiders?! Thank you

- Depends on geological reports, can not pile, it is best to save a lot of money Oh!

- Q: The grounding of piling machine. Pile machine, three-phase asynchronous motor one day to play 2 piles piling machine and control box are constantly moving, how to ground? And is not a machine box. A gate or a few feet to ground is the five core. In three, the rest of the root, the zero line and the PE are useless? Thank you, predecessors, great God under the guidance of? In this way, the master said that the reception will be over, installed a leak protection, is not installed, the leak insurance does not need to ground ah?

- The pile driver must be grounded reliably! Five core power cable, PE core wire may reach 16 square, in pile machine within 30 meters hit a 3 meter long galvanized angle (angle 50X5X3000), the head of a hole on the M10 (or M12) galvanized bolts, connecting 16 square BVR yellow green color line to the pile machine (repeat grounding), angle head (to prevent the hammer head welding deformation angle) a piece of iron, if you want to reuse (pull out in place again), can be connected with the hanging wire rope or a hook hole in angle steel.

- Q: What are the preparations for the piling site?

- 1, the pile position determination: according to the project provided by the construction unit and the pile axis location map of pile location, pile location must be accurate, and in the pile position by a soldering iron drilling, hole depth is 15~20cm, filled with lime, prevent in the process of driving the wrong pile.2. Pile up(1) pile stacking shall be determined by pile driving route and pile driving sequence(2) the site shall be level and level with three passes and one leveling. Remove obstacles in the ground, underground and air in the range of the moving of the pile driver. The wooden posts and the pile rings shall be of the same position, except for the contact between the pile and the pile, and nothing else shall be in contact with the pile so as to prevent cracks in the pile.(3) the strength of reinforced concrete precast piles must be up to 100% before they can be transported and piled3, the selection of pile machineAccording to the design of single pile bearing capacity and pile length, this project intends to use hammer weight 2.5t track type diesel pile driver.

- Q: What is the power of the pile driver?

- TDP at least 95W, full load, power consumption is greater. But relative to full load I7, the power consumption is low. For example, FX8300 is 23% lower than 3770K.

- Q: Code for installation and operation of pile drivers

- First, piling machine operators must be familiar with the structure of the machine, performance, operation essentials and safety precautions, after passing the test and obtain a certificate, you can operate alone.Two, operators must concentrate on the operation. Do not talk, laugh, play or make trouble with unrelated persons. No smoking or food is allowed during the operation.Three, strictly abide by the relevant provisions of the maintenance of pile drivers, conscientiously do all levels of maintenance, to ensure that pile drivers are often in good condition. And pay attention to the rational use, correct operation.Four, the pile driver in the work should be prepared for the following:1, to the construction staff understand the construction conditions and tasks, and construction problems found in this class should pay attention to matters.2. Adjust the position of the speed change gear of the pile driver according to the vibration force required by the construction personnel.3. Check whether the insulation of cables and wires is good. Check that the controller's contacts are good and that the bounds are correct.

- Q: Want to mortgage a hydraulic pile driver?. Excuse me, what brand, what tonnage is more competitive?.Could you introduce the profit, expense, cash flow of piling machine, the more detailed, the better.

- Yutong, 31 will do, pile driver according to drilling diameter, and drilling depth

- Q: I heard that the operation of the pile driver can make about ten thousand a month, is it possible? It sounds a bit dodgy. Who knows about this job? Please tell me how much you can make it for a month

- Generally similar, but if the site is more, then more than this money

- Q: Why do some people need to dig the foundation and pile it up to dig a hole?

- First of all, depends on the type of your pile, prefabricated or bored pile.If it is a bored pile, then it is obvious to dig first.If it is a prefabricated pile, then pile it directly, then dig it.

- Q: How much is the average cost of piling a metre?.Construction Engineering piling machine how much money? (can be more than 30) piling generally hit a meter, what is the cost?. How much can I pay for a metre? What's the procedure for piling operators?

- Domestic about 2000000, the best to count Germany and Italy one, at least 500 - about 6000000! About one meter. Need fifty or so, a twenty meters stake will not exceed one thousand dollars, the operation of pile machine need pile machine driver's license, also can hang some of the company's account.

- Q: Is there an operation certificate for percussive drill driver?

- The following is the introduction of can refer to the utility model relates to an automatic drill piling machine, the piling machine has a movable chassis, the chassis of the upper lateral order device PLC electric control box, automatic operation mechanism, hoisting part and a steering pulley and a main frame; PLC electric control box is provided with a computer program controller.

Send your message to us

KLB32-800 Bored Pile Drilling Rig for Sale

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 1000 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords