ZYC series ZYC600B-B multi-functional Hydraulic Static Pile Driver

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 1000 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

ZYC series multi-functional Hydraulic Static Pile Driver

Features:

Main product: ZYC series multi-functional Hydraulic Static Pile Driver Self-developed with 5 up-to-date patents.

The working principle is using hydraulic pressure to clamp precasted pile, H shape or other shape steel pile, and then driving the pile into ground by hydraulic pressing.

Suitable for piling precast round & square concrete pile, H shape steel pile and other irregular-shaped pile in clay, soft soil and sandy ground.

It has characteristics of no noise, no vibration, no pollution, clear ground with high speed of pile driving, reliable construction quality and environmental protection, high efficiency, energy saving. It is welcomed by the customers with wide market prospect.

● Flexible connection technology

Novel flexible connection technology of central axis, won national practical patent

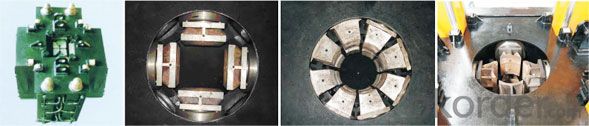

● Multi-functional piling technology

Original combination clamping piling and top piling won invention patent

● Inverted cylingder technology

Structure design of inverted cylinder changes strained condition of cylinder and increases the service life of cylinder, won national practical patent

● Integrative side and corner piling technology

Particular side and corner piling mechanism increasing the capability of side & corner piling and won national practical patent

Self-adaptive clamping mechanism

Original self-adaptive clamping mechanism won national practical patent

Parameters:

| Rated piling pressure(tf) | 600 | suitable pile & specification(mm) | ¢300-800 | |

| Max. Piling speed(m/min) | 5.9 | Max. Crane lifting weight(t) | 16 | |

| Piling stroke(m) | 2.0 | Hanging pile length(m) | 15 | |

| Max. Longitudinal pace(m) | 3.6 | Minimum side piling space(mm) | 1380 | |

| Max. Transverse pace(m) | 0.6 | Minimum corner piling space(mm) | 2800 | |

| Max. Rise stroke(m) | 1.1 | Intensity of pressure(tf/m²) | 12.96/16.6 | |

| Max.rotation angle per time(°) | 11° | Weight composition | (t) Machine weight | 180±3 |

| Rated hydraulic system pressure(mpa) | 24(20) | Added water weight(t) | 46 | |

| Hydraulic Pump (Unit × Ml/Turn) | 3×80 + 1×80 | Counter weight(t) | 375 | |

| Motor power (Unit × kw) | 3×37 + 1×30 | Total weight(t) ≥ | 600 | |

FAQ

To provide customers with professional and technical services, to meet the demands of customers for construction efficiency and cost control, to achieve value for customers, which is the constant pursuit of Toppile, Toppile implant this concept in the whole process of sales and services.

Before sales

Research market with customers; provide technical advice, customized design and production.

On sales

Always communicate and adjust of design with customer to ensure the product satisfy all requirements.

After sales

Provide installation, adjustment, maintenance service, create customers files, following up machine working situation, provide customer a whole set of “Butler” and “Gapless”services.

Value added services

Redesign and upgrade the hydraulic system of piling machine, upgrade structure components.

Provide high quality and lower price components.

Toppile is the agent of many components factories, including cylinders, pumps, seals, hydraulic elements.

- Q:How much are the pile and Larson piles of a pile driver?

- Would you like to ask the price of the material or the price of the construction?AskMaterial priceChasing the answerI mainly do Larson steel sheet pile products. Domestic 5000 or so, Japan imports 6450.

- Q:How many hydraulic pile drivers or diesel pile drivers are used in high-rise residential buildings?

- The precast pipe pile is mostly driven by diesel hammer pile machine (in particular, the use of static pressure pile machine).

- Q:What are the types of pile drivers?

- Pile driver is composed of pile hammer, pile support and auxiliary equipment. The pile hammer is attached to two parallel vertical guide rods (commonly called Longmen) at the front of the pile support and hoisted with lifting hooks. The pile foundation is a steel structure tower with a windlass at the back of which is used to lift the pile and hammer. A guide frame consisting of two guide rods is used in front of the pile to control the direction of the pile driving so that the pile can be accurately penetrated into the formation in accordance with the design orientation. The basic technical parameters of a pile driver are impact weight, impact kinetic energy and impact frequency.

- Q:How does a cement pile driver work?

- That's the gravity of the object itself

- Q:What's the special use of a pile driver?

- There are two main types of pile driver used at present: diesel hammer pile driver and long spiral drilling rig.In general, long spiral ring power head motor starting current depends on the specific circumstances, if the full voltage starting with load, the starting current is 5-7 times the rated current of the power supply. The construction of their equipment.

- Q:What's the use of a pile driver?

- It is a spiral into the hole, drilling, torsion, flexible application in different soil, different pile rod, a Hunan photovoltaic site ente spiral auger, the finished pile rod placed in a spiral drill under the hook on the second column, is a very typical case of PV column pile. With such an efficient job, wouldn't it make you realize your dream of getting your cost back in 10 days?In addition, it can be applied for diversified garden landscaping, well drilling, drilling, sampling, planting pit coal pillar foundation drilling, bridge with pit wells, drilling hole, wind generator column pole hole (hole) of the drill, expand your business to expand your money.Choose gornt heavy bosses don't have to worry about the machine idle.

- Q:What's the difference between a walking tube type diesel pile driver and a track type diesel pile driver?

- The piling machine works on the top and bottom of the pile hammer. The pile hammer moves up and down on the 2 rail. It is called a track type diesel pile driver, and the pile hammer operates in the pipe way up and down. It is called a tube type diesel pile driver

- Q:What are the characteristics of hydraulic static piling compared with traditional pile driver?

- The pile is pressed by its own weight. Besides the weight of the pile, the weight of the pile should be installed with a total weight of more than 600 tons to the thousand tons.There is a large power hydraulic pump station with maximum power of more than 300 kW at run time.The pressure prefabricated pipe pile is clamped by hydraulic cylinder and pressed down by segment. The noise and vibration are smaller, and the bearing capacity can be known.Pile with hook.

- Q:Invite friends together to buy a long spiral step of 30 meters of the pile driver, told me as long as the project profits are objective, you can package to 200W/, would like to ask the experts familiar with the bank bosses according to your local market if the annual package is how much money, how much is the monthly package, or by how many meters.. Thank you。。 Thank you

- 1, Shandong small 360 degree rotation of the kind of Shandong strong machinery factory, sold in about 6-8;2, long spiral pile driver is a long spiral drilling machine another name, later called long spiral drilling machine.

- Q:What kind of pile driver, rotary drilling machine can drill under medium weathering rock layer?

- The Xugong power head, wylong machinery mechanical lock rod rotary drilling rig Yuchai engine and can be weathered rock and sediment layer in the layer below, backfill soil drilling construction

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

ZYC series ZYC600B-B multi-functional Hydraulic Static Pile Driver

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 1000 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords