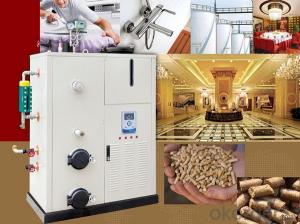

The Integrated Hot Blast Stove

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction:

The integrated hot-blast stove Brand: HUAYUAN

Specification: 116KW, 232KW, 349KW, 465KW, 581KW, 698KW, 1046KW

(please refer to service consultant for specific parameter)

Technical description:

1、could be used for such process requirement as paint, drying and heating.

2、hot blast temperature could be 280℃.

3、the material is heat-resistant because of long-time high temperature dry combustion.

4、the design construction of boiler should be exquisite, or the life-time will be greatly improved.

5、reduce the demand for pure wood fuel, which will reduce fuel cost correspondently.

6、design with our invention patent, which could burn all kinds of pellet fuel.

- Q: how many btu's is needed for a 3,400 sq ft living area house.

- Outdoor Wood Boilers (OWB) are being regulated or banned across the country. Although you may legally install an OWB chances are you could lose your investment if a neighbor complains about the significant smoke and odor emitted from these devises. There are now a number of attorneys taking OWB cases on contingency and suing owners, dealers, and the manufacturers for product deficiency. It has been proven that an OWB emits more PM 2.5 than allowed by law thereby making these types of cases a slam dunk for attorneys. Insurance companies are also raising rates because of the law suits. Look up NESCAUM on Google and once at their site select Outdoor Hydronic Heaters for additional info. Buy at your own risk.

- Q: boiler ton/hr

- a boiler which can covert one ton of water in to saturated steam in one hour.

- Q: what are boilers and what are they used for?

- they're used to heat up the water in your home for your central heating and baths and what not

- Q: I'm having trouble with physics revision and heat transfer. There's a question in the book about whether a boiler should be dark and matt or light and shiny, and I just don't understnad! Can someone explain it to me?

- Should be light shiny. A blackbody emits the most energy ata given temperature. Painting it black does not make it a perfect black body but it's better than white. cf. Stephan-Boltzmann law. The formula includes a coefficient expressing the degree to which a body is black. BTW 'black' in this case refers not only to visible light.

- Q: One, two, three boiler stove are equivalent to the boiler operation Ⅰ, Ⅱ, Ⅲ, which category

- Article 4 stipulates that the boiler operator refers to the use of the boiler unit engaged in the operation of the operation of the boiler personnel.

- Q: I assume that there was a ford or chevy of the boiler business. The builder must have had a economical boiler which was produced in quantity. Steam being new, or relatively so, the boiler would need to be cheap enough to allow businesses to experiment on steamboats, railroad locomotives, and factory drive shafts. Anybody know thename of the producer and when production got underway?

- The first viable engine that used steam was Newcomen's Atmospheric Engine, which was used commercially to pump water out of mines, invented 1712.

- Q: the little brown reset button on top of the boiler popped up a few times to start with but that stopped and instead now when we run the hot tap in the bath (downstairs bathroom with boiler in the bedroom above) it runs only luke warm. the kitchen tap runs hot as always and the only way we can get a decent temperature in the bath is by running the cold tap in the bathroom sink at the same time as the hot in the bath. does anyone know what the problem could be and if not, anyone know how much i'd be looking at for a new boiler, please?

- is the other taps getting hot water?if so the problem obviously is with the bath tap,or plumbing work underneath,do you have a mixer on the bath,or seperate pillar taps,if so trace back the pipework and find the mixer valve open it up for hot water to flow through-might also explain why your boiler is going onto overheat. if that does'nt work-what is the flow rate like?if poor that could trigger the limit stat,because the boiler can't disapate its heat. if the heat is still lukewarm and flow rate is good check the H/W thermistor on the boiler. also has the bath been refitted or moved,dead legs can trap air-you'd be looking for long pointless run of copper pipework that don't do anything

- Q: I was wondering how do you know if the boiler needs to add water from the pipe or the boiler is already full of water?

- Steam Boiler * Steam pressure gauge * Low water cut-out with water gauge glass Hot Water Boiler * Temperature and pressure gauge * Circulatory Both of these uses water. The steam boiler has a water gauge glass tube filled with water but to the 1/2 mark. This is one area where they don't have marking on it. Just 1/2 of the glass size in the middle you can mark it with a magic marker (black). The hot water boiler doesn't have this feature. With those boilers you don't have to check the water level. There should be a cold water intake value to add water to the water level on Steam Boiler. Also if you get your hot water for you hot/cold to take a shower, wash clothes, dishwasher, you might have the model that uses: Tankless coil domestic water heater - again these get filed with water automatically. The boiler will come on and off when the temp of the water is low. Settings 1 2 3 4-hottest on most tankless coil systems.

- Q: This is another new house queston. We have a boiler that sends forced hot water to heat our house. It also heats the hot water. I am new to this, we have always had a hot water heater in additon to the furnace. I like to keep the heat temp low. Would it make sense to have a seperate hot water heater installed to save on running the boiler for the hot water?

- It might. Depends on how old the boiler is, how big it is, and how efficient it is. MOF, since, with a seperate water heater, you can turn the boiler off during the warm months. This alone may well justify the cost of installing one. A lot depends on what kind of energy you'e using for the boiler, and where you are. Right now, in the Pacific Northwest, electricity is actually cheaper for heating than gas is! Go figure... I'd do an analysis: Turn everything off and run the hot water out of the tank. Record the reading on the meter. Run the boiler to heat the house, and record the meter reading again. Turn off the heat, run out the hot water again, repeat recordings. Compare the two. if it costs almost as much as, or even as little as a third as, much to heat the water as it does to heat the water and the house, I'd have to say, probably a good idea.

- Q: What is a boiler that is used to do anything

- Furnace is the place where the fuel is burned, including: furnace wall, insulation, steel frame and so on.

Send your message to us

The Integrated Hot Blast Stove

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords