Stainless Steel Insulated Storage Tanks for Sale

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 500 unit/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Description:

Processing: Storage Tank, cutting-rolling-welding-polishing-assembling-testing-warehousing

Condition: New

Place of Origin: Zhejiang, China (Mainland)

Brand Name: KUNBO

Model Number: bright tank, KB-006

Processing Types: Alcohol

Voltage: 380V, 50HZ

Certification: B&V; CE

Image:

Packaging & Delivery

| Packaging Details: | export standard package |

|---|---|

| Delivery Detail: | 25 - 45 days after deposit received |

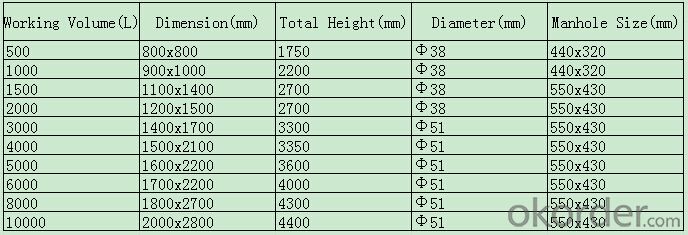

Specifications

1.manhole 2.CIP spraying ball 3.adjusting feet 4.sample valve 5.temperature gauge 6.pressure gauge 7.level gauge

Technical Data:

- Q: which kind of water tubes ( beside those with smooth surface) are used for boilers?

- Boilers also use finned tubes and studded tubes. These are typically used in the convection section of the boiler and the super heater. They can't be used in the fire box area due to the radiant heat flux. It will cause damage to the thin fins or studs.

- Q: we are trying to work out how we set the timer on it. it just has a dial with numbers up to 24 on it but theres not guide as to how we know when the heating will go on or off

- + I can't answer your question and the guy above seems to have the answer, but I recently saw something on your boiler and they indicated that you had like the very very best one, and the longest lasting one. I bet it cost a bundle. Love to find out how i

- Q: I live in the UK, in a 1970's ex local authority semi and it has the standard 'back' boiler which was fitted to many homes built at that time. After the recent gas bill rises I decided to turn the boiler down to hopefully reduce my energy bills but discovered that the boiler is on setting 2 (out of 5) My question is, would it be better to turn it down to 1 of in fact turn it up to 3 or even 4 making it run hotter and therefore reduce the amount of cutting in and out it does to heat the water tank. Basically I only have hot water on gas (heating is off at the mo) and it seems to be costing me around ?1.50 a day which does seem quite expensive for a couple of showers and some washing up per day.

- The hotter you keep your water, the more heat it will lose. The rate of heat loss is directly proportional to the difference in temperature between your boiler and the air around it. The number of times the burner cuts in and out is irrelevant; the only thing that matters is how long the burner is on in total. Answer: keep it as low as you can live with. More important to your heating costs is how much you let out the door (or the window or all of the other holes and cracks). If your water tank is not insulated, insulate it. Replace the weatherstrips on all your doors and windows. Caulk every crack or pin hole. If you can, double the amount of insulation in your attic. Think of your house as a slightly leaky pail, leaking your money -- i.e. your expensive heated air. Every pin hole you plug is money kept in your pocket.

- Q: Summary of safety knowledge

- In the event of an accident involving public safety, it will cause great losses to the state and people's lives and property.

- Q: What are the hazards of boiler water hammer accidents?

- When the water flows in the pipeline, sudden changes in pressure caused by sudden changes in pressure, the formation of pressure waves and the phenomenon of transmission in the pipeline, called water hammer.

- Q: I had a problem with heating system pump, it was screeching when I turned on the heating , I had the pump changed , now I can hear the pump working but the boiler comes on as usual and only works for between 30 seconds to 2 minutes, the pipe off the top of the boiler gets hot

- Almost sounds like the water is not circulating and the boiler is reaching temp and shutting down. If you have an amp meter try sticking that on one of the pump wires to make sure the pump is running. If it is, you may have a check valve stuck shut. I would call back the person you had change your pump and tell him you heat is not working. You mentioned the pipe off the top of the boiler gets hot, do the pipes 10-15ft away from the boiler on that same circuit get hot? If not than this again proves there is a restriction in the circuit. Good Luck!

- Q: Why is my radiator making the noise of running water, despite the heating being off and the radiator not being the least bit warm?It only does this occasionally. What is the most economic setting to have the boiler on?

- There probably is a leak, cuasing the boiler to have to refill with water. The most effective setting is to get the water hot enough so it does not have to keep running.

- Q: how do you bleed air from a boiler system?

- Boiler systems should have an automatic bleed valve at the high point in the piping. It may be called the air eliminator. Turn on your make-up supply and fill the system. Make sure your bladder tank has the proper charge and it should take care of itself..

- Q: after it`s cleaned up it doesn`t appear again during the evening, i am washing up and using the hotwater continuosly. It must come during the day while we are away. The hot water system is set to heat twice a day.

- It depends on where you notice leak Do you see it around perimeter of boiler? or directly under..It could be a leaky or cracked boiler or a relief valve leaking. When boiler heats up it expands so if it is a cast iron boiler it may be cracked and leaking when it heats up..Or .like I mentioned it could be the relief valve..Hope that helps you

- Q: I am having a problem with the pilot staying on in my boiler. I press the reset button and it will eventually come on. but after about 45 seconds it shuts back off. can someone shed some light on the problem. i dont feel like paying some one to fix this. there has to be something that I am overlooking.

- USA And the answer is - thermo couple!

Send your message to us

Stainless Steel Insulated Storage Tanks for Sale

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 500 unit/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords