Tabel formwork system for Formwork and Scaffolding Build

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Specifications:

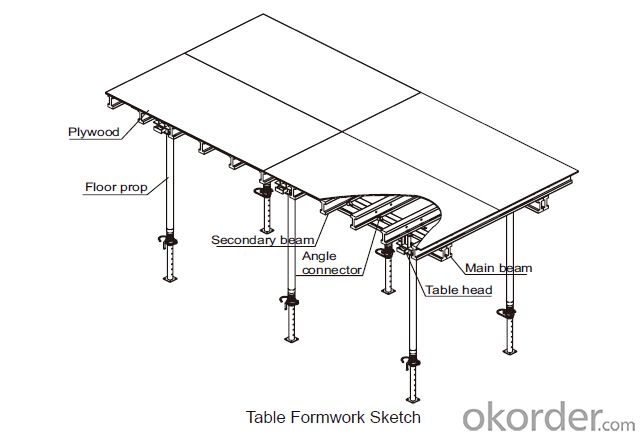

OKorder is offering high quality Building Scaffolding Table Formwork Systems at great prices with worldwide shipping. Table formwork is the most typical application, suitable for use with slabs or timber beam. Slab formwork is lightweight easy to erect and economical. Our supplier is a world-class manufacturer of scaffolding, and our products are utilized the world over, with OKorder annually supplying a full range of products to European, North American and Asian markets.

Product Applications:

Building Scaffolding Table Formwork Systems are for use in interior or exterior applications, and are designed to endure everyday use around a construction sites and remodeling projects.

Product Advantages:

OKorder's Building Scaffolding Table Formwork Systems help you get your project off the ground, with improved safety, economical construction and standardized parts.

Main Product Features:

· Improved safety with handrails

· Easy assembly

· Flexible structure, suitable for varied support systems

· Increases construction efficiency

· Formwork forklift and trolley compatible

· Flexible application with stand alone props

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered by OKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: What are the capacity requirements for all scaffolds?

A3: Each scaffold and scaffold component must support without failure its own weight and at least 4 times the maximum intended load applied or transmitted to it. Scaffolds and scaffold components must not be loaded in excess of their maximum intended loads or rated capacities, whichever is less. Load carrying timber members should be a minimum of 1,500 lb-f/in² construction grade lumber.

Q4: Should I use steel scaffolding or aluminum scaffold?

A4: If your job will run 6-8 weeks or more, steel scaffolding will actually be cheaper for you. Projects that run for a few hours to a few weeks are generally more practical and economical to do with aluminum scaffolding.

Q5: Is aluminum scaffold suitable for outdoor use?

A5: Aluminum scaffolding is designed to endure any weather conditions. It is tested to handle the cold winters of North America and Europe, and the extreme heats of Australia and Africa.

Q6: When should I order caster wheels versus leveling jacks?

A6: Order wheels for inside use. We do not recommend them outside unless on hard surface such as concrete or asphalt. Use level jacks outside or inside. Level jacks offer adjustability of the platform height of greater than 1500px.

Images:

- Q: Can steel formwork be used in areas with limited construction access roads?

- Yes, steel formwork can be used in areas with limited construction access roads. Unlike traditional formwork made of wood or other materials, steel formwork is durable, lightweight, and can be easily transported to remote locations. It can be disassembled and reassembled multiple times, making it suitable for areas with limited access roads where transportation of heavy construction materials is challenging. Additionally, steel formwork offers high strength and stability, ensuring the structural integrity of the construction even in difficult-to-reach areas.

- Q: What are the different types of formwork release oils used with steel formwork?

- Steel formwork commonly utilizes various types of formwork release oils to prevent concrete adhesion and facilitate easy removal. These oils include petroleum-based, vegetable-based, water-based, silicone-based, and polymer-based release agents. 1. Petroleum-based release oils, derived from petroleum, are frequently employed in construction projects. They effectively prevent concrete adhesion and enable effortless removal by acting as a barrier between the concrete and the steel formwork. 2. Vegetable-based release oils, such as soybean or canola oil, offer a more environmentally friendly alternative to petroleum-based oils. 3. Water-based release agents are a popular choice due to their non-toxic nature and absence of harmful fumes. They are easy to apply and provide excellent release effects on steel formwork. 4. Silicone-based release agents are renowned for their exceptional release properties. They create a thin layer on the steel formwork, preventing adhesion and ensuring effortless removal of the concrete. Additionally, they contribute to a high-quality finish on the concrete surface. 5. Polymer-based release agents are commonly utilized when a superior finish is desired for the concrete surface. These agents form a thin film on the steel formwork, preventing adhesion and facilitating easy stripping. Selecting the appropriate formwork release oil should be based on project-specific requirements, including the type of concrete, environmental considerations, and desired concrete surface finish. Consulting professionals or referring to manufacturer's guidelines is advisable to ensure the correct release oil is chosen.

- Q: What are the different sizes and dimensions of steel formwork panels?

- Steel formwork panels come in various sizes and dimensions to cater to different construction needs. The sizes and dimensions of steel formwork panels can vary depending on the manufacturer and the specific requirements of a project. However, there are some common sizes and dimensions that are widely available in the market. The standard dimensions of steel formwork panels usually range from 1.2 meters to 2.4 meters in length and 0.6 meters to 1.2 meters in width. These standard sizes are designed to be easily handled and transported on construction sites. Additionally, the thickness of steel formwork panels can vary between 3 millimeters to 6 millimeters, depending on the load-bearing capacity required. Apart from the standard sizes, custom sizes can also be manufactured to meet specific project needs. These custom sizes can be larger or smaller than the standard dimensions, depending on the complexity and scale of the construction project. In terms of weight, steel formwork panels are relatively heavy due to the material's durability and strength. The weight of a steel formwork panel can range from 30 kilograms to 50 kilograms, depending on its size and thickness. Overall, the sizes and dimensions of steel formwork panels can vary to accommodate different construction requirements. It is important to consult with a supplier or manufacturer to determine the most suitable size and dimension for a specific project.

- Q: What are the common design considerations for steel formwork in hot climates?

- When designing steel formwork for use in hot climates, there are several common considerations that need to be taken into account. 1. Thermal Expansion: Steel has a high coefficient of thermal expansion, meaning it expands and contracts with temperature changes. In hot climates, where temperatures can reach extreme levels, it is important to account for this expansion in the design of the formwork. Adequate expansion joints and allowances should be provided to accommodate the thermal movement of the steel. 2. Heat Resistance: Steel formwork should be designed to withstand high temperatures without significant deformation or loss of strength. This may involve selecting steel grades with higher heat resistance or employing additional cooling measures to prevent overheating. 3. Corrosion Protection: Hot and humid climates can accelerate the corrosion process, so it is important to incorporate effective corrosion protection measures into the design. This can be achieved through the use of corrosion-resistant coatings, such as galvanization or epoxy coatings, or by incorporating sacrificial anodes to protect the steel from corrosion. 4. Ventilation: Hot climates often require adequate ventilation to prevent the buildup of heat and moisture within the formwork. Properly designed openings and vents should be included to facilitate air circulation and prevent the formation of condensation, which can lead to corrosion and reduce the lifespan of the formwork. 5. Insulation: In extremely hot climates, insulation can help to reduce the transfer of heat to the formwork, minimizing the effect of thermal expansion and reducing the risk of deformation. Insulation materials, such as foam or reflective coatings, can be used to provide a barrier between the steel formwork and the external environment. 6. Durability: The design of steel formwork should take into consideration the long-term durability requirements of the project. This includes selecting materials and construction methods that are resistant to degradation from UV radiation, extreme temperatures, and other environmental factors commonly found in hot climates. Overall, designing steel formwork for use in hot climates requires careful consideration of thermal expansion, heat resistance, corrosion protection, ventilation, insulation, and durability. By addressing these factors, the formwork can withstand the challenges posed by hot climates and ensure the successful completion of construction projects.

- Q: Can steel formwork be used for marine construction projects?

- Yes, steel formwork can be used for marine construction projects. Steel has excellent strength and durability, making it suitable for withstanding the harsh marine environment. It offers stability and resistance to corrosion, making it a reliable choice for constructing structures in or near the water.

- Q: What are the considerations when designing steel formwork for stairs?

- Several important considerations must be kept in mind when designing steel formwork for stairs. Firstly, it is crucial to carefully calculate and design the structural integrity and load-bearing capacity of the formwork. Stairs experience significant dynamic loads from people walking up and down, so the formwork must be able to support these loads without any deformation or failure. Accurately determining the dimensions and shape of the stairs is also essential to ensure a proper fit within the formwork. This involves considering the rise, tread, and overall dimensions of each step, as well as any landings or platforms that may be present. The formwork needs to be designed to accommodate these dimensions while providing a smooth and safe construction surface. The construction process and ease of installation should be taken into account as well. The steel formwork for stairs should be designed to be easily assembled, disassembled, and transported to the construction site. It should also allow for easy access during the construction process, ensuring that workers can safely and efficiently complete their tasks. Durability and longevity are crucial factors when designing steel formwork for stairs. While steel is a strong and durable material, it is important to consider the potential for corrosion and wear over time. The design should incorporate proper coatings and protective measures to prevent corrosion and ensure the formwork's longevity. Finally, safety is of utmost importance when designing steel formwork for stairs. The formwork should be designed to provide a secure and stable working platform for construction workers. This may involve incorporating handrails, non-slip surfaces, and other safety features to minimize the risk of accidents or falls during construction. In conclusion, when designing steel formwork for stairs, it is important to consider factors such as structural integrity, dimensions, ease of installation, durability, and safety. By carefully considering these factors, a well-designed steel formwork system can be created to efficiently and effectively construct stairs in a safe and reliable manner.

- Q: Can steel formwork be used for both residential and commercial construction projects?

- Yes, steel formwork can be used for both residential and commercial construction projects. Steel formwork is versatile and durable, making it suitable for various types of construction projects. It offers high strength and stability, allowing for efficient and precise construction of both residential and commercial structures.

- Q: How does steel formwork handle concrete temperature differentials?

- Steel formwork is known for its strength and durability, which allows it to effectively handle concrete temperature differentials. The thermal conductivity of steel helps in evenly distributing the heat or cold generated by the concrete during the curing process. This prevents the formation of cracks or other structural issues that can occur due to uneven temperature distribution. Additionally, steel formwork provides stability and rigidity, ensuring that the concrete maintains its desired shape and strength even when exposed to varying temperatures.

- Q: Can steel formwork be used for both residential and industrial construction projects?

- Yes, steel formwork can be used for both residential and industrial construction projects. Steel formwork is highly versatile and can withstand heavy loads, making it suitable for various construction applications. Its durability and strength make it ideal for use in both residential and industrial settings.

- Q: How does steel formwork handle different concrete testing procedures?

- Steel formwork is highly versatile and can easily handle different concrete testing procedures. Its sturdy and strong structure ensures that it can withstand the pressure and weight of the concrete during testing. Additionally, steel formwork provides a smooth and even surface, which is crucial for accurate testing results. It can also be easily dismantled and reassembled, making it convenient for various testing procedures. Overall, steel formwork is well-suited to handle different concrete testing procedures due to its durability, stability, and adaptability.

Send your message to us

Tabel formwork system for Formwork and Scaffolding Build

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches