Tabel Formwork System for Formwork and Scaffolding Build

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Specifications:

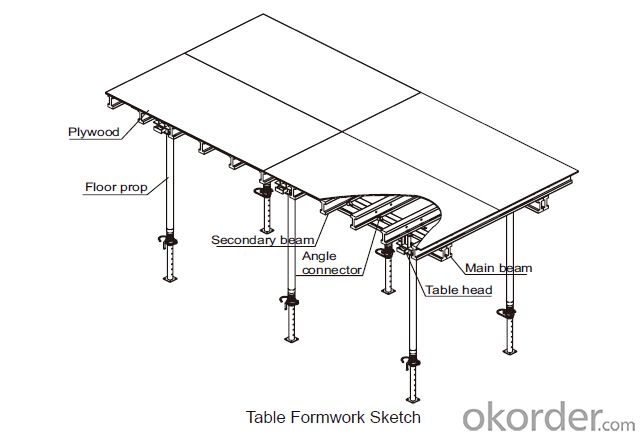

OKorder is offering high quality Building Scaffolding Table Formwork Systems at great prices with worldwide shipping. Table formwork is the most typical application, suitable for use with slabs or timber beam. Slab formwork is lightweight easy to erect and economical. Our supplier is a world-class manufacturer of scaffolding, and our products are utilized the world over, with OKorder annually supplying a full range of products to European, North American and Asian markets.

Product Applications:

Building Scaffolding Table Formwork Systems are for use in interior or exterior applications, and are designed to endure everyday use around a construction sites and remodeling projects.

Product Advantages:

OKorder's Building Scaffolding Table Formwork Systems help you get your project off the ground, with improved safety, economical construction and standardized parts.

Main Product Features:

· Improved safety with handrails

· Easy assembly

· Flexible structure, suitable for varied support systems

· Increases construction efficiency

· Formwork forklift and trolley compatible

· Flexible application with stand alone props

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered by OKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: What are the capacity requirements for all scaffolds?

A3: Each scaffold and scaffold component must support without failure its own weight and at least 4 times the maximum intended load applied or transmitted to it. Scaffolds and scaffold components must not be loaded in excess of their maximum intended loads or rated capacities, whichever is less. Load carrying timber members should be a minimum of 1,500 lb-f/in² construction grade lumber.

Q4: Should I use steel scaffolding or aluminum scaffold?

A4: If your job will run 6-8 weeks or more, steel scaffolding will actually be cheaper for you. Projects that run for a few hours to a few weeks are generally more practical and economical to do with aluminum scaffolding.

Q5: Is aluminum scaffold suitable for outdoor use?

A5: Aluminum scaffolding is designed to endure any weather conditions. It is tested to handle the cold winters of North America and Europe, and the extreme heats of Australia and Africa.

Q6: When should I order caster wheels versus leveling jacks?

A6: Order wheels for inside use. We do not recommend them outside unless on hard surface such as concrete or asphalt. Use level jacks outside or inside. Level jacks offer adjustability of the platform height of greater than 1500px.

Images:

- Q: Can steel formwork be used for precast concrete wall panels?

- Precast concrete wall panels can indeed utilize steel formwork. Steel formwork boasts numerous advantages in precast concrete construction. With its high strength, durability, and dimensional accuracy, steel formwork guarantees the production of top-quality wall panels. Moreover, steel formwork can be easily reused multiple times, presenting a cost-effective solution. Additionally, its installation process is quick and efficient, leading to reduced construction time. The malleability of steel formwork allows for the creation of wall panels in various shapes and sizes, accommodating the design requirements of diverse projects. Consequently, steel formwork emerges as a fitting choice for precast concrete wall panels, offering an array of benefits in terms of strength, durability, efficiency, and cost-effectiveness.

- Q: Can steel formwork be used for both thin and thick concrete elements?

- Indeed, both thin and thick concrete elements can be constructed using steel formwork. The versatility of steel formwork allows for easy adjustments and modifications to accommodate varying concrete thicknesses. This attribute contributes to its suitability for a wide range of construction projects, including walls, columns, beams, slabs, and intricate architectural structures. Furthermore, steel formwork ensures a seamless and accurate finish to the concrete, guaranteeing exceptional quality outcomes. Moreover, the durability of steel formwork permits its repeated use, rendering it a cost-effective option for both thin and thick concrete elements.

- Q: What are the common design considerations for steel formwork in marine environments?

- In order to design steel formwork for marine environments, it is important to take into account several common considerations. These considerations are crucial to guarantee the durability and longevity of the formwork in the challenging marine environment. Some of the commonly considered design factors for steel formwork in marine environments are as follows: 1. Selecting the Right Materials: It is essential to choose appropriate materials that can withstand the corrosive effects of saltwater. To prevent rusting and deterioration, stainless steel or other corrosion-resistant alloys should be utilized. 2. Coatings and Surface Treatments: The application of protective coatings or surface treatments can enhance the corrosion resistance of the steel formwork. These coatings may include zinc-rich primers, epoxy coatings, or galvanization, which provide an extra layer of protection. 3. Reinforcement and Strengthening: Marine environments subject the formwork to significant forces like waves, currents, and impact from floating debris. To ensure structural integrity, reinforcement and strengthening measures, such as additional bracing or thicker steel sections, may be necessary. 4. Proper Drainage and Ventilation: Adequate drainage and ventilation play a crucial role in preventing the accumulation of water, which can accelerate corrosion. Designing the formwork with suitable drainage channels or weep holes can help eliminate trapped moisture. 5. Attention to Connection Details: Special consideration should be given to connection details in marine environments. To prevent premature failure due to corrosion, corrosion-resistant fasteners like stainless steel bolts or galvanized screws should be used. 6. Regular Maintenance and Inspection: Regular maintenance and inspection are vital to identify any signs of corrosion or damage. Scheduled cleaning, removal of marine growth, and the application of protective coatings as needed will help prolong the life of the formwork. 7. Environmental Factors: The marine environment is often exposed to extreme conditions such as high winds, tidal forces, and UV radiation. The design should take these factors into account to ensure that the formwork can withstand these environmental loads. In conclusion, designing steel formwork for marine environments requires careful consideration of material selection, coatings, reinforcement, drainage, connection details, maintenance, and environmental factors. By incorporating these considerations into the design process, engineers can ensure that the formwork will withstand the harsh marine conditions and provide a reliable and durable solution.

- Q: How does steel formwork affect the overall acoustics of the building?

- Steel formwork can have a significant impact on the overall acoustics of a building. Due to its dense and rigid nature, steel formwork tends to reflect sound waves instead of absorbing them. This reflection can cause an increase in overall noise levels and create echoes within the building. The use of steel formwork can result in a higher reverberation time, which is the time it takes for sound to decay by 60 decibels. This can lead to poor speech intelligibility and reduced clarity of audio within the space. Additionally, the sound reflections from steel formwork can interfere with the natural acoustic properties of the room, potentially causing distortion and resonance issues. To address these challenges, sound-absorbing materials can be added to the interior surfaces of the building. This can help to reduce the reflection and reverberation of sound waves, improving the overall acoustics of the space. Options include the use of acoustic panels, insulation materials, and ceiling treatments that absorb and diffuse sound. It is important to consider the specific requirements of the building and its intended use when deciding on the type of formwork to be used. For spaces where good acoustics are crucial, such as auditoriums, concert halls, or recording studios, alternative formwork materials that provide better sound absorption properties may be preferred over steel formwork. However, in other applications where acoustics are less critical, steel formwork can still be used effectively with the addition of appropriate sound-absorbing measures. Overall, the choice of steel formwork can have a significant impact on the acoustics of a building. Proper consideration of sound absorption and reflection properties, along with the use of additional acoustic treatments, can help to mitigate any negative effects and create a more pleasant and functional acoustic environment.

- Q: How does steel formwork ensure accurate concrete dimensions and alignment?

- Steel formwork ensures accurate concrete dimensions and alignment by providing a rigid and stable structure that holds the concrete in place during the pouring and curing process. The steel formwork is designed and fabricated to precise specifications, allowing for precise shaping and positioning of the concrete. The use of steel formwork also reduces the risk of deformation or shifting during the concrete setting, ensuring that the final dimensions and alignment of the concrete structure are maintained.

- Q: How does steel formwork handle different concrete surface coloring techniques?

- Steel formwork is a versatile and durable material that can handle different concrete surface coloring techniques effectively. The primary advantage of using steel formwork is its smooth and non-porous surface, which ensures that the concrete's coloring techniques are evenly applied and achieve the desired result. When it comes to concrete surface coloring techniques such as staining, stamping, or integral coloring, steel formwork provides a stable and consistent base for these processes. The smooth surface of steel formwork allows for an even distribution of colorants or pigments, ensuring that the final concrete surface has a uniform and appealing appearance. Additionally, steel formwork's strength and rigidity make it suitable for various concrete surface coloring techniques. Whether it is stamping, which involves pressing textured patterns onto the concrete surface, or staining, which requires precise application of colorants, steel formwork provides the necessary support and stability for these techniques to be executed accurately. Furthermore, steel formwork's durability makes it resistant to damage during the coloring process. Concrete surface coloring techniques often involve the use of chemicals, dyes, or stains that can potentially cause damage to weaker or less resistant formwork materials. However, steel formwork's robustness allows it to withstand the harsh chemicals and coloring agents without compromising its structural integrity. In summary, steel formwork is an excellent choice for handling different concrete surface coloring techniques. Its smooth and non-porous surface ensures even distribution of colorants, while its strength and rigidity provide the necessary support for techniques such as stamping or staining. Additionally, steel formwork's durability makes it resistant to damage caused by chemicals or coloring agents, ensuring a successful and aesthetically pleasing outcome.

- Q: How does steel formwork handle different concrete segregation tendencies?

- Steel formwork is highly effective in handling different concrete segregation tendencies due to its strength and durability. It provides a rigid structure that minimizes the risk of concrete segregation during the pouring and curing process. The smooth surface of steel formwork prevents the accumulation of excess water or aggregates, reducing the chances of segregation. Additionally, steel formwork can be easily adjusted and reinforced to accommodate varying concrete placement methods, ensuring uniform distribution and minimizing the potential for segregation.

- Q: How does steel formwork contribute to the overall safety of workers?

- Steel formwork contributes to the overall safety of workers by providing a sturdy and reliable structure for concrete construction. Its strength and durability minimize the risk of collapse or accidents during the construction process, ensuring the safety of workers. Additionally, steel formwork is designed to be easily assembled and disassembled, reducing the labor and time required for installation and minimizing potential hazards.

- Q: What are the different types of ties used with steel formwork?

- There are several types of ties commonly used with steel formwork, including snap ties, taper ties, she-bolts, wedge bolts, and pins. These ties help secure the formwork panels together and ensure the stability and strength of the structure being formed.

- Q: Does steel formwork require any special training or expertise for installation?

- Installation of steel formwork necessitates specific training and expertise. This intricate system is employed in concrete construction to establish temporary molds or frameworks. The process of installation entails the meticulous assembly and fixation of steel panels, beams, and other components to guarantee the desired shape and strength of the concrete structure. To properly install steel formwork, one must possess knowledge of construction techniques, an understanding of engineering principles, and familiarity with the project's specific design and requirements. Additionally, proficiency in reading technical drawings, interpreting structural plans, and accurately calculating the dimensions and quantities of the steel formwork components is crucial. Moreover, the installation process may entail the utilization of heavy machinery, such as cranes or lifting equipment, to position and secure the steel formwork. Handling and operating such equipment necessitate specialized training to ensure safety and efficiency. Improper installation of steel formwork can result in structural weaknesses, compromised concrete quality, and safety hazards. Consequently, it is imperative to enlist the services of trained professionals who possess the necessary skills and experience to effectively undertake the installation process. In conclusion, given the technical nature and significance of steel formwork in concrete construction, the installation process demands special training and expertise. By employing qualified professionals with the requisite knowledge and skills, the successful implementation of the formwork system is guaranteed, leading to the creation of safe and high-quality concrete structures.

Send your message to us

Tabel Formwork System for Formwork and Scaffolding Build

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches