Tabel Formwork Systems for Formwork and Scaffolding Build

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

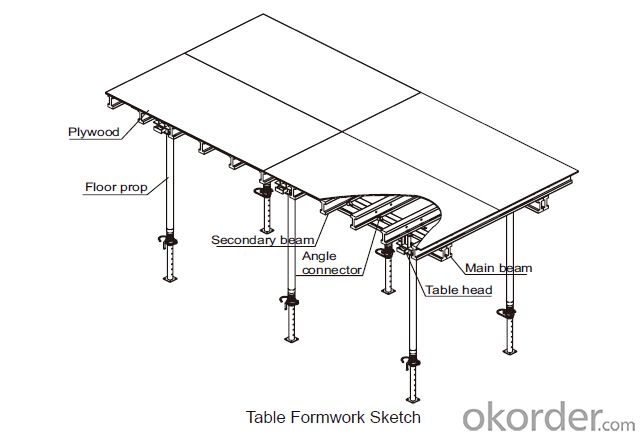

Tabel Formwork:

Table formwork is the most typical application for slab, with timber beam, the slab formwork is

light weight, fast and economic in the construction.

Characteristics:

◆ Simple structure, easy assembly.

◆ Flexible structure, be adapted to different support system.

◆ High construction efficiency with special system tools.

1. Lifting fork for lifting the table formwork to upper floor.

2. Trolley for moving the table formwork on floor.

◆ Flexible application with stand alone props.

◆ Safer condition with handrails.

- Q: Can steel formwork be used for elevated walkways?

- Steel formwork is indeed suitable for constructing elevated walkways. It is a highly versatile and durable construction material that can be used for various applications, including the construction of elevated walkways. The strength and stability of steel formwork systems make them ideal for supporting the weight and load of a walkway. By using steel formwork for elevated walkways, one can ensure the creation of a safe and robust structure capable of withstanding heavy foot traffic and adverse weather conditions. Moreover, steel formwork allows for flexibility in design, enabling the construction of customized walkways with different shapes and sizes. In conclusion, steel formwork is a reliable choice for constructing elevated walkways due to its strength, durability, and versatility.

- Q: Can steel formwork be used in seismic areas?

- Yes, steel formwork can be used in seismic areas. Steel is a strong and durable material that can withstand the forces generated during an earthquake. Additionally, steel formwork provides a stable and rigid structure, which is important in seismic areas to ensure the safety and stability of the construction.

- Q: Can steel formwork be used for both small and large-scale construction projects?

- Yes, steel formwork can be used for both small and large-scale construction projects. Steel formwork offers several advantages such as durability, reusability, and flexibility. It can withstand high pressure and loads, making it suitable for large-scale projects that require heavy concrete pouring. Additionally, steel formwork's modular nature allows for easy customization and adaptation to different project sizes and designs. This makes it equally suitable for smaller construction projects, where a quick and efficient formwork system is required. Steel formwork also provides a smooth and high-quality finish to concrete structures, ensuring a consistent appearance regardless of the project scale. Overall, steel formwork is a versatile and reliable choice for both small and large-scale construction projects.

- Q: How does steel formwork accommodate for different concrete curing methods?

- Due to its durability, flexibility, and ease of use, steel formwork is a versatile construction material that can accommodate various concrete curing methods. To begin with, different curing methods can be employed with steel formwork, including wet curing, dry curing, and accelerated curing. Wet curing involves maintaining the concrete's moisture and hydration for a specific period, while dry curing involves controlling the concrete's environment with low humidity. On the other hand, accelerated curing utilizes external heat sources to expedite the curing process. Steel formwork is particularly suitable for wet curing as it effectively retains moisture and prevents water loss from the concrete. The tightly fitted steel panels create a watertight enclosure that minimizes evaporation. This ensures that the concrete remains adequately hydrated during curing, promoting proper strength development and minimizing the risk of cracking or shrinkage. Likewise, steel formwork easily accommodates dry curing methods. The steel panels act as a barrier between the concrete and the surrounding environment, allowing precise control of humidity levels. This is especially beneficial in hot or dry climates, where maintaining a low humidity environment is critical for preventing premature moisture loss and ensuring proper curing. Furthermore, steel formwork is compatible with accelerated curing techniques. Its ability to withstand high temperatures makes it suitable for applications where external heat sources are used to expedite the curing process. The steel panels can withstand elevated temperatures without warping or compromising their structural integrity. Additionally, steel formwork can be easily adjusted or modified to meet specific curing requirements. The modular nature of steel formwork allows for flexibility in design and construction. By rearranging or adding steel panels, the formwork can be customized to create different shapes, sizes, or configurations. This flexibility is particularly advantageous when dealing with complex or unique concrete structures. In summary, steel formwork is a reliable choice for accommodating various concrete curing methods. Its durability, flexibility, and adaptability make it the preferred option in construction projects that require precise control over the curing process to achieve optimal concrete strength and quality.

- Q: What are the typical deflection limits for steel formwork systems?

- The deflection limits of steel formwork systems can vary depending on various factors, such as the project's specific design and application requirements. However, there are commonly followed general guidelines. In most cases, the deflection limits for steel formwork systems are determined based on the span length and the applied load. Typically, deflection limits are restricted to L/360 or L/240, where L represents the span length of the formwork. For instance, if the formwork's span length is 10 feet, the deflection limit would be L/360, which is approximately 0.028 feet or 0.34 inches. This means that the maximum allowable deflection for this formwork system would be 0.34 inches, ensuring stability and minimal deformation under the load. It should be noted that these deflection limits may be adjusted according to project requirements or industry standards. In high-rise construction projects, stricter deflection limits may be enforced to ensure the formwork system's structural integrity and overall safety. Ultimately, careful consideration and evaluation of deflection limits are necessary during the design and construction process of steel formwork systems. Consulting a structural engineer or referring to relevant industry standards can provide more accurate and specific deflection limits for a given system.

- Q: Can steel formwork be used for pre-stressed concrete elements?

- Yes, steel formwork can be used for pre-stressed concrete elements. Steel formwork provides high strength and durability, making it suitable for handling the high stresses and pressures involved in the pre-stressing process. Additionally, steel formwork allows for precise shaping and alignment of pre-stressed concrete elements, ensuring accurate results.

- Q: Can steel formwork be used for bridge piers?

- Bridge piers can indeed utilize steel formwork. This alternative is incredibly adaptable and long-lasting, making it appropriate for constructing a wide range of structures, including bridge piers. It presents several benefits, such as exceptional strength, effortless assembly and disassembly, and the ability to accommodate various designs. By employing steel formwork, one can accurately shape and reinforce bridge piers, guaranteeing their structural soundness and stability. Moreover, steel formwork can withstand the immense loads and pressures that bridge piers encounter throughout their existence. Consequently, steel formwork is a dependable and widely employed option when constructing bridge piers.

- Q: Can steel formwork be customized for specific project requirements?

- Yes, steel formwork can be customized for specific project requirements. Steel is a highly versatile material that can be easily molded and shaped according to the specific needs of a project. This allows for the creation of various sizes, shapes, and designs to accommodate different construction requirements. Steel formwork can be easily modified or adjusted on-site to meet the specific dimensions and specifications of a project. Additionally, steel formwork can also be pre-fabricated off-site, where it can be tailored to the exact requirements of the project before being transported to the construction site. This customization of steel formwork ensures that it can be effectively used in a wide range of construction projects, including complex structures, high-rise buildings, bridges, tunnels, and more.

- Q: Can steel formwork be used for single-sided formwork applications?

- Yes, steel formwork can be used for single-sided formwork applications. Steel formwork is known for its strength and durability, making it suitable for various construction applications, including single-sided formwork. It provides excellent support and stability to the concrete during pouring and curing processes, ensuring a smooth and efficient construction process.

- Q: Can steel formwork be used for both interior and exterior concrete elements?

- Yes, steel formwork can be used for both interior and exterior concrete elements. Steel formwork offers high strength, durability, and stability, making it suitable for various applications in construction, including both interior and exterior concrete elements.

Send your message to us

Tabel Formwork Systems for Formwork and Scaffolding Build

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches