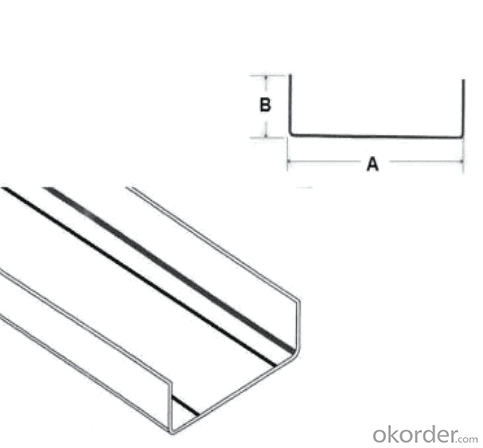

Steel Profile-Drywall Grid System for Partition

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 40000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

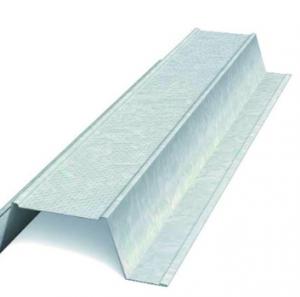

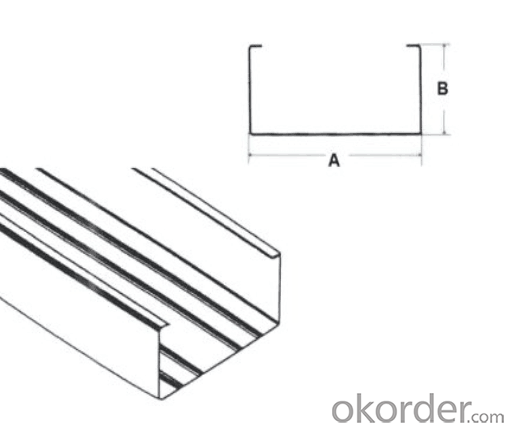

Steel Profile for Ceiling and Partition System

Drywall steel profiles are widely used in buildings for ceiling & partition systems with different kinds of boards, such as gypsum board, calcium silicate board, magnesium oxied board, fiber cement board... Drywall steel profiles are made of galvanized steel, and can be installed easilly. Besides, thermal and acoustic insulation products maybe filled in partition system to provide a safe and fire-resistant wall, and create a quiet environment.

Specification of Drywall Steel Profile:

Size: Different series of sizes for different markets

Thickness: 0.40~1mm

Length: normal 3m/piece

Zinc-coating: normal 50~60g/m2, or to order

Packing of Drywall Steel Profile:

Pcs into a bale (normally pack by tapes), bales into containers / wagon

Delivery of Drywall Steel Profile:

From Xingang (port) or Tianjin (station), 3 weeks in receipt of advance payment

Installation of Partition with Drywall Profiles and Accessories:

1. Marking

2. Fix the stud and track

3. Install the steel channel

4. Install the boards

5. Jointer application (accessories, screw, jointer, tape, insulation material)

- Q:What kind of new material is now called a "light partition" in the house? Is it safe?

- Light steel keel inorganic composite board partition is a high toughness material, compared to the traditional partition, better shock resistance. In the simulation of super 8 earthquake experiment, the traditional block wall has long been decomposed collapse, but the light steel keel inorganic composite board wall is still solid and reliable, showing its seismic capacity far more than the traditional wall, which is light steel Keel inorganic composite board partition in Japan widely used reasons, security is the primary consideration of residential construction factors.

- Q:Light steel keel wall gypsum board seams how to deal with? Including smallpox

- First with gypsum board filling material to fill the gap, in the bandage, and then touch the strap on the 2 - 3 layer of joints, with sandpaper tied on the line friends

- Q:Light steel keel wall waterproof

- The grass on the surface of the gray skin with a knife to remove, with a broom to dust, sand and other debris clean, especially the root, floor drain and drain and other parts to be carefully cleaned. If there is oil, apply wire brush and sandpaper brush off. The base surface must be flat, the depression should be filled with cement putty.

- Q:Light steel keel wall cheap or cheap red brick

- Now the sand is soaring, if the area is large, short-term is certainly selected light steel keel, if it is their own long-term use, it is still a brick, expensive on your point!

- Q:The designer said the solid wood flooring keel hit the prefabricated board after the lack of effort in the future may not be strong?

- 1: you have the conditions or bricklayers, practice: build the wall of the place, you can add a reverse beam (plus a beam on the floor) and then wall, reinforced concrete beam; another direct to do the word steel or channel to do Beam, pay attention to the two heads to be on the point of support. Build the wall again. ? 2: do light steel keel gypsum board wall accidentally wear a hole. Is a short time to be. Not moisture, is easy. 3: the floor can be made of wood, the material with a little bigger. Encrypt a little bit. The problem is not big, other solid floor to do on the ground fixed point has changed the day.

- Q:Light steel keel + gypsum board wall and other wall joints how to strengthen?

- Distance can be used with nail gun, more than 10cm above hanging with a large crane

- Q:I was not a tool in the category, or else I got myself!

- Look at the size of the area. Small words are generally not the unit price of the normal words is to use a gypsum board with a gypsum board is 65 - 75 range.

- Q:How to install damping sound insulation felt

- 1, along the wall laying sound insulation felt, seam at the pressure seam processing; ???? 2, the installation of vibration keel, wedge around 600mm; keel gap filled with cotton; ???? 3, vibration-proof keel installed on the noise board (two-layer board clip insulation felt, sheet and sound insulation stitch treatment)

- Q:How to do woodworking partition wall, with door

- Wooden skeleton should use specifications for 40 mm × 70 mm red, from pine. The spacing of the keel should take into account the size of the panel, usually between 450 and 600 mm If there is a door, both sides should establish a vertical keel. The dragon keel should be connected with the lordel open rod, the window on the bottom and the top of the door should be installed along the horizontal keel installed along the ground, along the top wood Leng, the corners should be stretched into the brick at least l20 mm, To ensure that the partition wall and the original structure of the wall connected firmly.

- Q:Waterproof gypsum board for toilet partition and paste tile installation steps?

- Bathroom wall on the calcium silicate board filled with less than 3CM steel mesh; fixed with a code nail gun; and then use 1: 3 of the cement mortar smear 2-3CM thick. After leveling the hair according to the normal process of paving wall.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Steel Profile-Drywall Grid System for Partition

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 40000 pc/month

Offcanvas right

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords