Tencate Mirafi Geogrids Plastic Grass Paving Grid / Plastic Parking Grass Grid / Parking Grass Grid Manufacturer

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m

- Supply Capability:

- 50000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

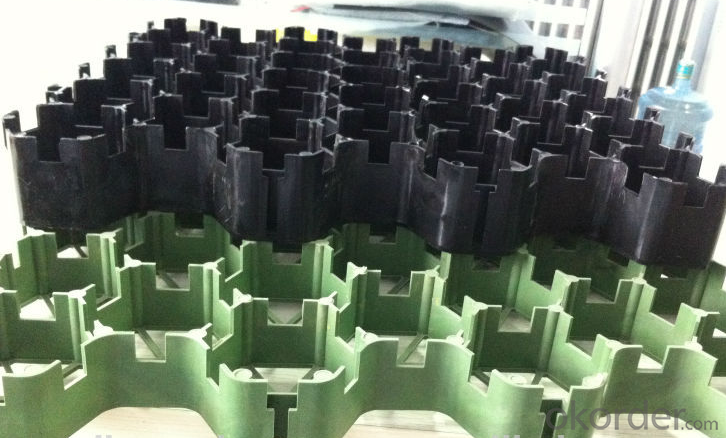

| Type: | Geogrids,Geomembranes | Place of Origin: | Shandong China (Mainland) | Brand Name: | Cmax |

| Model Number: | 001 | material: | HDPE | color: | green/black |

| certification: | CE /ISO9001 |

Packaging & Delivery

| Packaging Detail: | regular package or at requested |

| Delivery Detail: | within 7 days afetr advanced pament is received |

Specifications

Plastic grass grid:

1). completely greening

2) save investment

3) smooth surface

4) high strength

Plastic grass grid:

Plastic grass grid specifications:

make grass lawn and carprk two-in -one

HDPE materail, eco-friendly

proof pressure, wear- resisting, shock resistance,

Plastic grass grid Types:

hexagonal grass paver and circular grass paver

Height: 3.8cm, 5cm, 7cm

APPLICATIONS

Parking Lots (Grass or Gravel) & Overflow Parking

Overflow grass car & bus parking lots

Grass parking areas

Fire Truck Access routes / Fire Lanes

Helipads / Helicopter landing pads

Grassed light aircraft / airplane transport areas / taxiways

Handicap access routes

Golf cart paths

Emergency access roads

Residential access and parking spaces

Grass Driveway and grass shoulders

Polymer Density | High Density Polyethylene with density of 0.935 - 0.965 g/cm3 ASTM D 1505 |

Environmental Stress Crack Resistance | > 4000 hours ASTM D 1693 |

Carbon Black Content | Carbon black content 1.5% - 2.0% ASTM D 1603 |

Sheet Thickness | Smooth:1.1mm,1.2mm,textured:1.5mm ,1.7mm ASTM D 5199 |

Cell Details | welding distance:330-1000mm |

Cell Depth | 50-250mm |

Seam Peel Strength | As per US Army Corps of Engineer's Report GL-86-19 Appendix A |

Seam Hang Strength | A 100mm wide seam sample supports a 72.5 kg load for a minimum of 30 days in an ambient room temperature environment. |

Certification | CE ,ISO |

Classification | 1. smooth surface without hole 2. smooth surface with hole 3. textured surface with hole 4. textured surface without hole |

Plastic grass grid Characteristics:

1). completely greening

2) save investment

3) smooth surface

4) high strength, long service life

- Q: Can geogrids be used in shoreline protection applications?

- Yes, geogrids can be used in shoreline protection applications. Geogrids are commonly used to stabilize soil and prevent erosion, making them an effective solution for protecting shorelines from wave action and water currents. They can be installed in various configurations, such as beneath riprap or as a reinforcement layer for soil, to enhance the stability and longevity of shoreline protection measures.

- Q: How do geogrids help in reducing carbon footprint in construction projects?

- Geogrids help in reducing carbon footprint in construction projects by providing reinforcement to soil structures, thereby reducing the need for additional materials like concrete or asphalt. This results in a decrease in the usage of fossil fuel-based materials and the associated carbon emissions during production and transportation. Additionally, the use of geogrids reduces the need for excavation and land disturbance, which further minimizes carbon emissions and the environmental impact of construction projects.

- Q: What are the factors that affect the quality of glass fiber reinforced plastic grid

- Synthetic resin. Synthetic resin is used as the substrate of glass fiber reinforced plastics, which is used to paste the glass fiber into a whole. Because the resin is the base material, it has influence on the elastic modulus, heat resistance, electrical insulation, permeability, chemical corrosion resistance, weather resistance, aging resistance and so on.In addition, the interface is also an important factor affecting quality. The high performance of glass fiber reinforced plastic (FRP) grid cover is related to the quality and durability of the interface between fiber and resin. The interface has a great influence on the performance of glass fiber reinforced plastic grid. As everyone knows, the glass fiber is a cylindrical glass surface, such as glass, smooth, and the surface is often firmly adsorbed with a thin layer of water film, which certainly affect the bonding properties of glass fiber and resin. Especially in textile glass fiber drawing process, in order to achieve the collection, lubrication, eliminate the static, often coated with a layer of wetting agent, the wetting agent is the most paraffin substances remained on the surface of glass fiber on them, the isolation effect on synthetic resin and glass fiber, with both adhesive.

- Q: How many square meters of geogrid?

- Geogrid is a kind of main geosynthetics, which has unique properties and effects compared with other geosynthetics. Geogrid is often used as reinforcement of reinforced soil structure or composite material. The geogrid is composed of plastic geogrid, steel plastic geogrid, fiberglass geogrid and polyester warp knitted polyester geogrid

- Q: Asked the retaining wall engineering grille mistook polypropylene as high density polyethylene, how to do? Is there any remedy?

- What is wrong with the polypropylene in the geogrid in the retaining wall of the road? Performance will not be affected? Is there any remedy?

- Q: Are geogrids resistant to acid degradation?

- Yes, geogrids are generally resistant to acid degradation. They are commonly made from materials such as polypropylene or polyester which have excellent resistance to acidic environments. This resistance allows geogrids to maintain their structural integrity and performance even when exposed to acidic conditions.

- Q: Can geogrids be used in retaining walls for residential applications?

- Yes, geogrids can be used in retaining walls for residential applications. Geogrids provide additional reinforcement to the soil, improving stability and preventing potential wall failure. They are commonly used to increase the strength and durability of retaining walls in residential settings, ensuring long-term performance and safety.

- Q: Are geogrids effective in preventing soil erosion on slopes without vegetation?

- Yes, geogrids can be effective in preventing soil erosion on slopes without vegetation. Geogrids are engineered materials made from synthetic polymers, which are typically placed within the soil to reinforce it and provide stability. They help to distribute the forces acting on the soil and increase its shear strength, thus reducing the risk of erosion. However, it is important to note that geogrids alone may not be a long-term solution. It is recommended to combine them with other erosion control measures, such as hydroseeding or erosion control blankets, to achieve optimal results.

- Q: How do geogrids improve the performance of mechanically stabilized slopes in cold climates?

- Geogrids improve the performance of mechanically stabilized slopes in cold climates by providing reinforcement and stabilizing the soil, preventing slope failure due to freeze-thaw cycles. The geogrids act as a reinforcement layer, increasing the tensile strength and improving the overall stability of the slope. Additionally, they distribute the loads more evenly, reducing differential settlements and enhancing the slope's resistance to deformation caused by temperature fluctuations.

- Q: How do geogrids improve the load distribution in pavements?

- Geogrids improve the load distribution in pavements by providing reinforcement and increasing the stability of the structure. They distribute the load more evenly across the pavement, reducing stress on the layers beneath. This helps to prevent cracking, rutting, and other forms of pavement distress, ultimately extending the lifespan of the pavement.

Send your message to us

Tencate Mirafi Geogrids Plastic Grass Paving Grid / Plastic Parking Grass Grid / Parking Grass Grid Manufacturer

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m

- Supply Capability:

- 50000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords