Tencate Mirafi PP Biaxial Plastic Geogrid

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 2000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of Geogrid:

PP biaxial plastic geogrid is manufactured from polypropylene; it is produced through the process of extruding, punching, heating, longitudinal stretching ad transverse stretching.

Applications of Geogrid:

Make reinforce treatment for various kinds of soft soil foundation to evenly distribute load stress and reduce uneven settlement, not easy to generate static electricity, and flammability property good in the coal mine. It is easy to wash coal.

Used in highway, railway, port, airport and municipal project. Support in the recovery working face of coal mine and roadway in the coal mine.

Index Properties | Test Method | Unit | GG1515 | GG2020 | GG3030 | GG4040 |

MD TD | MD TD | MD TD | MD TD | |||

Polymer | -- | -- | PP | PP | PP | PP |

Minimum Carbon Black | ASTM D 4218 | % | 2 | 2 | 2 | 2 |

Tensile Strength@ 2% Strain | ASTM D 6637 | Kn/m | 5 5 | 7 7 | 10.5 10.5 | 14 14 |

Tensile Strength@ 5% Strain | ASTM D 6637 | Kn/m | 7 7 | 14 14 | 21 21 | 28 28 |

Ultimate Tensile Strength | ASTM D 6637 | Kn/m | 15 15 | 20 20 | 30 30 | 40 40 |

Strain @ Ultimate Strength | ASTM D 6637 | % | 13 10 | 13 10 | 13 10 | 13 10 |

Structural Integrity | ||||||

Junction Efficiency | GRI GG2 | % | 93 | 93 | 93 | 93 |

Flexural Rigidity | ASTM D 1388 | Mg-cm | 700000 | 1000000 | 3500000 | 10000000 |

Aperture Stability | COE Method | mm-N/deg | 646 | 707 | 1432 | 2104 |

Dimensions | ||||||

Roll Width | -- | M | 3.95 | 3.95 | 3.95 | 3.95 |

Roll Length | -- | M | 50 | 50 | 50 | 50 |

Roll Weight | -- | Kg | 39 | 50 | 72 | 105 |

MD denotes Machine direction. TD denotes transverse direction. | ||||||

Property of Geogrid:

1.) Improve roadbed bearing capacity,enlarge road lifetime.

2.) Prevent road collapse and crack

3.) Prevent soil and water loss in slope

4.) Could replace steel-plastic geogrid in coal mine.

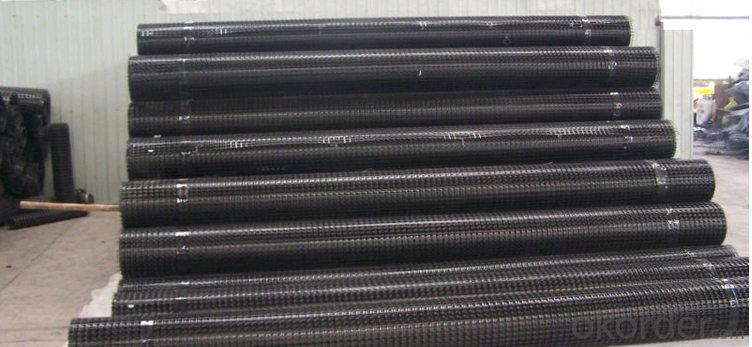

Packaging & Delivery

| Packaging Details: | Rolls in bulk, |

| Delivery Detail: | 7 days after recipt buyer's deposit |

FAQ:

1. How to order your geogrid ?

a). Tensile strength in warp & weft direction

b). Grid size

c). Width and length

d). Quantity

2. Payment term .

a) TT

b) LC AT SIGHT

c) cash

d) 30% contact value as deposit ,the blance 70% be paid after received the copy of bl .

3. Delivery time

a) 19-25 days after received your depsit .

4. What is MQQ ?

a) 2500 m2 as MQQ , we can also produce sample for you .

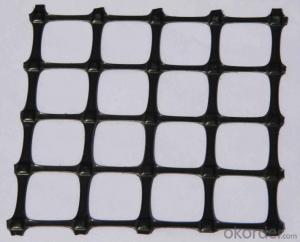

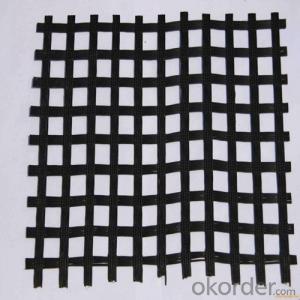

Geogrid Show:

- Q: Can geogrids be used in reinforced concrete pavements?

- Yes, geogrids can be used in reinforced concrete pavements. Geogrids are commonly used as a reinforcement material in concrete pavements to enhance their structural integrity, reduce cracking, and increase their load-bearing capacity. The geogrids work by distributing the load more evenly, reducing the stresses on the concrete and preventing the formation and propagation of cracks.

- Q: How do geogrids improve the performance of flexible pavements?

- Geogrids improve the performance of flexible pavements by enhancing their structural integrity and overall stability. They act as reinforcement materials, distributing the load and reducing the stresses on the pavement layers. This helps to prevent the formation of cracks, rutting, and other forms of pavement distress, ultimately extending the lifespan of the pavement.

- Q: How are geogrids installed in construction projects?

- Geogrids are typically installed in construction projects by first clearing and preparing the site, followed by laying a layer of geotextile fabric over the prepared area. The geogrid is then unrolled and placed on top of the fabric, ensuring proper alignment and overlap. The edges of the geogrid are secured using pins or stakes. Finally, the geogrid is covered with additional layers of soil, aggregate, or asphalt, depending on the specific project requirements.

- Q: Which is the most suitable for Highway Subgrade

- This depends on the Oh, you have no requirements on the design drawings, did not require the general steel plastic geogrid, plastic geogrid can be.

- Q: What are the cost considerations for using geogrids in construction projects?

- Some cost considerations for using geogrids in construction projects include the initial cost of purchasing and installing the geogrids, the potential cost savings in terms of reduced excavation and material requirements, the long-term durability and maintenance costs, and the overall benefits and value that geogrids can provide to the project.

- Q: Unidirectional tensile plastic geogrid manufacturers which good

- As the polymer in the manufacture of plastic polymer in the process of heating with the extension of the process of re orientation, strengthen the link between the molecular chain force, to achieve the purpose of improving its strength. Its elongation rate is only 10% ~ ~ of the original plate of 15%

- Q: Can geogrids be used in shoreline erosion control?

- Yes, geogrids can be used in shoreline erosion control. Geogrids are synthetic materials that can reinforce and stabilize soil, preventing erosion. When properly installed, they can help to protect shorelines from the destructive forces of waves and currents, thereby reducing erosion and preserving the integrity of the shoreline.

- Q: What is the typical lifespan of geogrids?

- The typical lifespan of geogrids can vary depending on several factors such as the type of geogrid, the site conditions, and the level of maintenance. However, on average, geogrids are designed to last for approximately 20 to 50 years.

- Q: How do geogrids help in reducing the risk of foundation settlement?

- Geogrids help in reducing the risk of foundation settlement by providing additional support and stability to the soil beneath the foundation. They act as a reinforcement material that enhances the load-bearing capacity of the soil, preventing it from shifting or settling. This helps distribute the weight of the structure more evenly, reducing the potential for uneven settlement and potential damage to the foundation.

- Q: Are geogrids suitable for use in landfill liners?

- Yes, geogrids are suitable for use in landfill liners. They provide effective reinforcement and stabilization, enhancing the overall performance and longevity of the liner system. Geogrids help to distribute load stresses, prevent soil erosion, and improve slope stability, making them a reliable and beneficial component in landfill liner design.

Send your message to us

Tencate Mirafi PP Biaxial Plastic Geogrid

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 2000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords