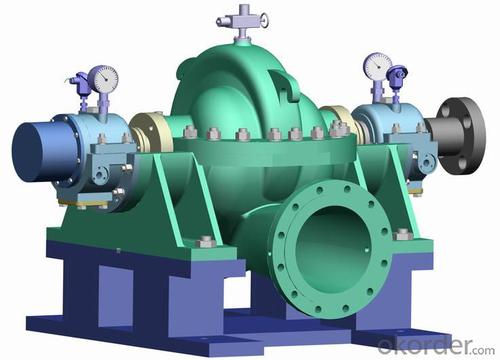

Split Case Pumps Double Suction Water Pumps

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 1000 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Split Case Pumps Double Suction Water Pumps

Application

Single Stage Double Suction Split Case Pump is used for conveying water or the physical and chemical properties similar to water and other liquids suitable for factories, mines, urban water supply, power stations, agricultural irrigation and water conservancy.

Characteristic

Compact structure,beautiful outline,stable operation,low noise;

Both inlet and outlet of this pump are placed under the axial line,so it is unnecessary to remove the inlet and outlet pipeline and motor;

The shaft seal of water pump has fine mechanical seal and soft stuffing seal,which can be selected according to different condition by user;

The impeller is static-balance calibrated,fixed on the shaft with round nut,and its axial position can be adjustedvia the round nut;

The pump is direct drived by motor via resilient coupling,it can be drived by internal combustion engine if it is necessary.

Technical Data

| Capacity | 50-20000m3/h |

| Head | 10-230m |

| Speed | 2900/1450/980/740/580/3500/1750/1180/890/710rpm |

Material

Casing: Cast iron/ ductile cast iron/cast steel/stainless steel/duplex stainless steel

Impeller: Cast iron/ ductile cast iron/brone/stainless steel/duplex stainless steel

Shaft:C-steel/stainless steel

The rotation direction

Viewed from motor, the direction of the pump is anti-clockwise,that is the suction in the left, the discharge in the right.

The rotating direction of the type pump is clockwise, that is the suction in the right, the discharge in the left.

Also can move the driver to another edge according to the user’s requires. Then, the rotating direction, the suction and discharge direction is in the opposite as the described above.

Photo

- Q: About 3 weeks ago our water stopped. We replaced the switch at the pump and it was fine. Today when I was running water, it stopped again. I went and flipped the breaker on it, but it still didn't come on. About 20 minutes later, it started working again. Have you ever had this happen or do you know what the problem could be?

- You mentioned that you flipped the breaker...was the breaker tripped? If so...then your pump is overheating, and tripping the breaker. Possibly some bare wires rubbing together in the well pipe might cause it too. If the breaker isn't tripping...then you may have a problem with the well itself. If it's going dry...the pump will shut itself down when the water stops flowing through it...rather than sit there and run until it burns itself up! Hopefully it's just a bad breaker! :-) Good Luck!!

- Q: directions on changing water pump 2001 gmc pickup

- Changing a water pump is nothing special, just common sense. Drain the coolant and take apart whatever you need to get access to it. The cooling system is sealed off from everything else (like the oil system or example) so there shouldn't be any nasty surprises. Make sure you get a new set of any seals and gaskets with the new pump. However you may have to take off the timing belt to get at the pump, and you need the proper instructions for replacing that. Usually it is not recommended to re-use the old belt. You might be able to save a bit of money by not replacing any tensioner pulleys etc that should be changed when the belt is changed, depending how old they are. If you can afford the extra time off the road, don't buy replacement parts till you have looked at the condition of the old ones. Unless it is actually leaking water, pumps can last a long time making horrible noises (especailly noises at engine idling speeds), so you might consider leaving the pump till the next timing belt change anyway.

- Q: My father in law has a 95 jeep grand cherokee with the v~8 engine, the water pump started leaking so we went to autozone and bought a brand new duralast one with new gaskets, I'm gonna be putting it in when the weather lets me since i have to do it out on the street in front of the house, i was just wondering if anyone on here had any tips for me since i have never done one, I'm not a mechanic but i work on all my own vehicles since i am too poor to take them to a shop, i know a lot more about cars than he does so he asked me to help, it didn't look to hard but i'm not quite sure what im getting myself into, any advice or tips about this job is greatly appreciated. And please don't post telling me to take it to a mechanic as this is not a option for us, i will get it done i just thought somebody could help make it go a lil smoother with some pointers... Thanks

- This Site Might Help You. RE: Any tips on changing water pump on 95 jeep grand cherokee? My father in law has a 95 jeep grand cherokee with the v~8 engine, the water pump started leaking so we went to autozone and bought a brand new duralast one with new gaskets, I'm gonna be putting it in when the weather lets me since i have to do it out on the street in front of the house, i was...

- Q: how to replace water pump 97 pontiac bonneville?

- There's okorder /

- Q: someone told me my water pump may be going out and it sounds like their is a loose barron inside of it, so how much is it and and if i was to have someone else to fix it how much will it cost me

- This should be a V6 engine correct. if looking at front of engine,toward the belt , the water pump is located behind pulley appox. 5 inches on the side toward radiator. highest pulley on right side of engine. Replacement can be performed easily without many special tools.. First loosens each of the pulley bolts on pump. Then release tension on belt and route away from pulley. Remove remaining pulley bolts and pulley , Water pump has 5 bolts holding it to cover assembly, Mark-index the way pump installs and remove. Clean all gasket material. Install new pump and gasket, refill system and to open air blled on cooler pipe near water pump to allow air to escape.

- Q: I want to run 1 HP, 220 v, single phase water pump on solar panels without using any batteries. what do I need to do so amp; how do I wire it?

- Does a great job of increasing global warming as well, as the waste energy becomes what = HEAT!

- Q: can this happen that pump is pressurizing system and no flow in suction.

- Hi, It seems to me your question is miss- worded or it simply flew over over my head. I'm intending the same project when time is there for it. I m a' machine builder by trade as also an oilfeild welder so tend to trust my plans about design. My answer to your question is you can't suck water from a plugged pipe except one tiny amount that would create a vaccum. My plan is an inline hot water pump(automotive type) to go to and from the water heater while the pluming route may have radiators or other heat transfer sourses like plane pipeat various points of the house return in an open pipe flow lie.Thermostate control hooked tothe electric motor that drives the water pump

- Q: How important is a torque wrench,if so what is the proper fp torque for pump/pulley ?

- It shouldn't be that critical for water pump bolts. It is extremely important for something like engine head bolts because of the extreme pressures inside the cylinders. Just refrain from over-tightening. I've replaced a number of water pumps and have never used a torque wrench.

- Q: I recently got the water pump replaced on a 99 Oldsmobile Intrigue GL (3.5L V6), and ever since the temperature gage seems to be running higher...between half way and the 3rd line, where before it was replaced it never got above the second line. It is doing this when I slow down and stop at lights. Once I get going the temperature does drop. Is this normal, or did they do something wrong?

- It means the fan isn't working. No air is going through the radiator at low speeds.

Send your message to us

Split Case Pumps Double Suction Water Pumps

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 1000 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords