Solar Panel Silicon Wafer PV Solar Panel Price / Solar Cell / Solar Module

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 watt

- Supply Capability:

- 10000 watt/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

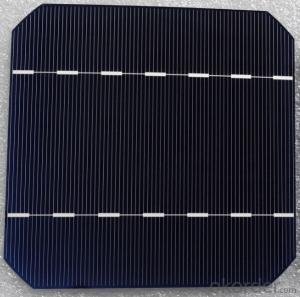

PV Solar Panel Price / Solar Cell / Solar Module

type:156M

appearance:156×1565㎜±0.5mm;diagonal:R=100mm

Main fence wide:1.4-1.5mm back electrode wide:2-2.5mm

Fence line qty:90

Cell thickness:220um±20um

Eff(%) | 18.00- 18.10 | 18.10- 18.20 | 18.20- 18.30 | 18.30- 18.40 | 18.40- 18.50 | 18.50- 18.60 | 18.60- 18.70 | 18.70- 18.80 | 18.80- 18.90 | 18.9- 19.0 | 19.1- 19.1 | 19.1- 19.2 |

Pm(W) | 4.30 | 4.33 | 4.35 | 4.37 | 4.40 | 4.42 | 4.44 | 4.47 | 4.49 | 4.52 | 4.54 | 4.56 |

Isc(A) | 8.71 | 8.73 | 8.76 | 8.77 | 8.78 | 8.82 | 8.83 | 8.85 | 8.86 | 8.88 | 8.9 | 8.93 |

Im(A) | 8.19 | 8.21 | 8.24 | 8.26 | 8.30 | 8.33 | 8.35 | 8.39 | 8.42 | 8.45 | 8.47 | 8.51 |

Voc(V) | 0.630 | 0.631 | 0.632 | 0.633 | 0.634 | 0.634 | 0.635 | 0.636 | 0.637 | 0.637 | 0.638 | 0.64 |

Vm(V) | 0.527 | 0.528 | 0.529 | 0.531 | 0.531 | 0.532 | 0.534 | 0.534 | 0.535 | 0.536 | 0.537 | 0.538 |

FF(%) | 78.6 | 78.7 | 78.8 | 79.0 | 79.2 | 79.3 | 79.5 | 79.6 | 79.8 | 80 | 80 | 80 |

Product Show

Shipping

1. Shipment shall be made only after PAYMENT is received.

2. Please do inform us your DETAILED ADDRESS AND CONTACT INFOMATION before shipment.

3. Shipment shall be made in THREE WORKING DAYS.

- Q: How do solar silicon wafers contribute to reducing the reliance on imported energy?

- Solar silicon wafers contribute to reducing the reliance on imported energy by enabling the production of solar panels, which generate electricity from sunlight. By harnessing renewable energy sources like solar power, countries can reduce their dependence on imported fossil fuels and traditional energy sources. This shift towards locally produced solar energy helps to decrease the need for importing energy, leading to greater energy independence and reducing the strain on foreign energy supplies.

- Q: How do solar silicon wafers contribute to sustainable development goals?

- Solar silicon wafers contribute to sustainable development goals by enabling the production of clean and renewable energy. These wafers are the key component in solar panels, which generate electricity by harnessing the power of the sun. By utilizing solar energy, we reduce dependence on fossil fuels and mitigate greenhouse gas emissions, thereby combating climate change. Additionally, solar silicon wafers promote energy access and affordability, especially in remote areas without reliable electricity grids. This technology supports sustainable development goals by facilitating the transition to a more sustainable, low-carbon future.

- Q: The higher the resistivity of silicon wafers, the better?!!! 1 experts please answer me!

- Weak questions: why single crystal resistivity in about 1 would be better?

- Q: Polished silicon wafers can be most SEM substrates

- There are many kinds of polishing, mechanical polishing, chemical polishing, electrolytic polishing, ultrasonic polishing, fluid polishing, magnetic abrasive polishing!Beijing there throwing a new type of practical technology, science and technology can improve the Liz polishing efficiency and so on.

- Q: Can solar silicon wafers be used in solar-powered telecommunications systems?

- Yes, solar silicon wafers can be used in solar-powered telecommunications systems. Solar silicon wafers are commonly used in photovoltaic cells to convert sunlight into electrical energy, which can be utilized to power various devices including telecommunications systems.

- Q: How much does a solar silicon wafer weigh?

- A solar silicon wafer typically weighs around 4 to 6 grams. However, the weight can vary depending on the size and thickness of the wafer.

- Q: I would like to ask the solar cell (silicon) production process is the principle of how

- Two, the surface of cashmereThe preparation of single crystal silicon wafer is the use of anisotropic etching of silicon on the surface of the silicon per square centimeter to form several million square pyramidal structure, namely, the Pyramid structure. Due to the multiple reflection and refraction of incident light on the surface, the absorption of light is increased, and the short circuit current and conversion efficiency are improved. Anisotropic etching of silicon in alkaline solution liquid is usually hot, available alkali sodium hydroxide, potassium hydroxide, lithium hydroxide and ethylenediamine etc.. Most of them were prepared by using dilute sodium hydroxide solution with a concentration of about 1%, and the corrosion temperature was 70-85. In order to obtain a uniform texture, but also in the solution add alcohols such as ethanol and isopropanol as complexing agent to accelerate the corrosion of silicon. In the preparation of velvet, the silicon chip must be first surface corrosion, alkaline or acidic etching solution to about 20 ~ 25 m, corrosion in the face, the general chemical cleaning. After surface preparation of silicon wafers are not suitable for long-term storage in the water, in order to prevent contamination, should be spread as soon as possible.

- Q: What is the effect of surface passivation on solar silicon wafers?

- The effect of surface passivation on solar silicon wafers is to reduce the recombination of charge carriers at the surface, thereby improving the overall efficiency of the solar cell. Surface passivation helps to minimize the loss of electrons and holes, which can significantly enhance the power output and performance of the solar cell.

- Q: What are the main factors that affect the lifespan of a solar silicon wafer?

- The main factors that affect the lifespan of a solar silicon wafer include exposure to sunlight, temperature variations, material defects, and chemical degradation. Continuous exposure to sunlight can cause the wafer to degrade over time due to the accumulation of photons and heat. Temperature variations, especially extreme heat, can lead to thermal stress and expansion/contraction cycles that can weaken the wafer. Material defects, such as impurities or structural imperfections, can decrease the wafer's performance and durability. Additionally, chemical degradation caused by exposure to moisture, pollutants, or corrosive substances can also contribute to the degradation of the wafer over its lifespan.

- Q: Can solar silicon wafers be used in water desalination plants?

- Yes, solar silicon wafers can be used in water desalination plants. These wafers can be used to harness solar energy and convert it into electricity, which can then be utilized to power the desalination process. By using solar energy, desalination plants can become more sustainable and environmentally friendly.

Send your message to us

Solar Panel Silicon Wafer PV Solar Panel Price / Solar Cell / Solar Module

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 watt

- Supply Capability:

- 10000 watt/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords