Prime square alloy steel billet 90mm Q235

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

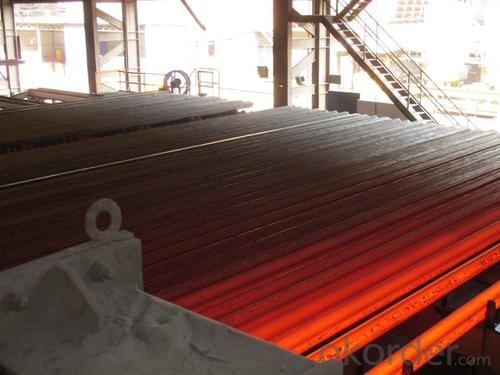

Structure of Prime square alloy steel billet 90mm Q235

Description of Prime square alloy steel billet 90mm Q235

1. Prepainted steel coil is coated with organic layer, which provides higher anti-corrosion property and a longer lifespan than that of galvanized or galvalume steel sheets.

2. The base metals for prepainted steel coil consist of cold rolled, HDGI Steel, electro-galvanized and hot-dip alu-zinc coated steel. The finish coats of prepainted steel coil can be classified into groups as follows: polyester, silicon modified polyesters, polyvinylidene fluoride, high-durability polyester, etc.

3. The production process has evolved from one-coating-and-one-baking to double-coating-and-double-baking, and even three-coating-and-three-baking.

4. The color of the prepainted steel coil has a very wide selection, like orange, cream-colored, dark sky blue, sea blue, bright red, brick red, ivory white, porcelain blue, etc.

5. The prepainted steel coils can also be classified into groups by their surface textures, namely regular prepainted sheets, embossed sheets and printed sheets.

Main Feature of Prime square alloy steel billet 90mm Q235

1. Thickness: ≥20μm

2. Pencil Hardness: 2H

3. 60° specular glossiness of coating: >60

4. 180°bend: ≤3T

5. Impact: ≥9J

6. Salt Fog Resistant: ≥500h

7. Color difference:<0.8δe< span="">

Applications of Prime square alloy steel billet 90mm Q235

Manufacture Progress:HRC-CRC-GALVANIZED-COLOR COATED

Application : Construction, electrical, transportation, steel plant, composite board plant, steel tile factory

Payment & Shipping Terms:T/T ,L/C, and FOB CHINA

Minimum Order Quantity: 25Tons

Packge Type: Moisture-proof paper inner,Steel outside,Bundle by steel rope.

Package in Container : Wood as a foot pad, wire rope reinforcement,PPGI steel coil tied together by steel rope.

Specifications of Prime square alloy steel billet 90mm Q235

Product | Billet |

Material Grade | SGCC / SGCH / DX51D+AZ, etc |

Thickness | 0.6-3.0mm |

Width | 500-1500mm |

Tolerance | Thickness: +/-0.02mm , Width:+/-2mm |

Zinc-coating | Z30-150g/m2 |

Technique | Raw material: Hot rolled steel coil --> Cold rolled_>hot dipped galvalume |

Surface | Dried, Chromated, Unoiled |

Spangle | Regular spangle , small spangle, zero spangle |

ID | 508MM 610MM |

Coil weight | 1-25MT |

Export package | Cardboard inner sleeves, Waterproof paper, galvanized steel covered and steel strip packed |

FAQ of Prime square alloy steel billet 90mm Q235

We have organized several common questions for our clients,may help you sincerely:

1. How Can I Visit There?

Our company is located in Tianjin City, China, near Beijing. You can fly to Tianjin Airport Directly. All our clients, from home or aboard, are warmly welcome to visit us!

2. How Can I Get Some Sample?

We are honored to offer you sample.

3. Why choose CNBM?

we always fix steel produce in container well to make it safe arrive at destination port

we always provide best and professional forward service for our buyer

we always apply 14days free detention for our buyers container in destination

we provide one set After-sales service for our buyer

we provide China inland steel market price report

we help our buyer become number one in local market .

- Q: What is the average lifespan of a steel billet in the automotive industry?

- The average lifespan of a steel billet in the automotive industry can vary depending on several factors such as the specific application, type of steel used, and maintenance practices. However, on average, steel billets in the automotive industry can last for several years to decades, especially when properly cared for and maintained.

- Q: How do steel billets contribute to the overall noise reduction of a structure?

- Steel billets can contribute to the overall noise reduction of a structure by providing a dense and heavy material that helps to absorb and dampen sound vibrations. When used in construction, steel billets can be strategically placed to create barriers that block and reflect noise, reducing its propagation and minimizing the impact of external noise sources on the structure's interior.

- Q: What is the role of steel billets in the manufacturing of railway signaling systems?

- Steel billets play a crucial role in the manufacturing of railway signaling systems. These billets serve as the primary raw material for the production of various components that are essential for the functioning of these systems. Railway signaling systems are responsible for ensuring the safe and efficient movement of trains on the tracks. They comprise a complex network of electrical and mechanical devices that control the traffic flow, provide information to train operators, and maintain a safe distance between trains. To manufacture these systems, steel billets are utilized in several ways. Firstly, steel billets are used to produce the structural components of railway signaling systems. These components include signal poles, posts, and brackets that support the signaling devices such as lights, signals, and indicators. Steel is chosen for these structural elements due to its high strength, durability, and resistance to environmental factors such as wind, rain, and temperature fluctuations. Secondly, steel billets are employed in the production of various electrical components used in railway signaling systems. These components include wiring conduits, junction boxes, and mounting plates that house and protect the electrical connections and circuitry. Steel's electrical conductivity properties make it an ideal material for these applications. Additionally, steel billets are also utilized in the manufacturing of mechanical components within railway signaling systems. These components include gears, levers, and linkages that facilitate the movement and operation of the signaling devices. Steel's mechanical properties, such as its hardness and ability to withstand high loads, ensure the reliability and longevity of these mechanisms. In summary, steel billets are essential in the manufacturing of railway signaling systems as they provide the necessary raw material for the production of structural, electrical, and mechanical components. Their strength, durability, electrical conductivity, and mechanical properties make them well-suited for the demanding requirements of these systems, ultimately contributing to the safe and efficient operation of railways.

- Q: How do steel billets compare to other types of metal billets?

- Steel billets generally have several advantages over other types of metal billets. Firstly, steel is known for its strength and durability, making steel billets a reliable choice for various applications. Steel billets also have excellent heat and corrosion resistance, enhancing their longevity and performance. Additionally, steel billets offer a wide range of alloying possibilities, allowing for customization and the creation of specific properties for different applications. Overall, the superior strength, durability, and versatility of steel billets make them a preferred choice in many industries compared to other types of metal billets.

- Q: Can steel billets be used for structural applications?

- Yes, steel billets can be used for structural applications. Steel billets are semi-finished products that are typically produced through a continuous casting or hot rolling process. They have a rectangular cross-section and are used as raw material for further processing into various shapes and forms, including structural components. Steel billets possess several properties that make them suitable for structural applications. Firstly, steel is known for its high strength and durability, which allows it to withstand heavy loads and resist deformation. This makes steel billets a reliable choice for constructing buildings, bridges, and other infrastructure projects. Additionally, steel billets can be easily fabricated into different shapes and sizes to meet the specific requirements of a structural application. They can be further processed through techniques such as hot rolling, forging, or extrusion to produce beams, columns, bars, and other structural elements. Moreover, steel billets offer good weldability, which allows for the joining of individual components to create larger structures. This makes them an ideal material for construction projects where prefabrication and on-site assembly are common practices. Overall, steel billets are widely used in structural applications due to their high strength, versatility in fabrication, and excellent mechanical properties.

- Q: What are the specifications for tool steel billets used in the manufacturing of cutting tools?

- The specifications for tool steel billets used in the manufacturing of cutting tools can vary depending on the specific application and requirements. However, there are some general specifications that are commonly followed. 1. Composition: Tool steel billets are typically made from high-carbon alloy steels that contain elements such as chromium, molybdenum, vanadium, tungsten, and cobalt. These alloying elements enhance the hardness, wear resistance, toughness, and heat resistance of the tool steel. 2. Hardness: Tool steel billets are required to have a high hardness to withstand the demanding cutting conditions. The hardness is typically measured on the Rockwell C (HRC) scale, and it can range from 58 HRC to 65 HRC or even higher for certain applications. 3. Wear Resistance: Cutting tools are subjected to abrasive wear during operation. Therefore, tool steel billets are formulated to have excellent wear resistance properties to ensure a longer tool life. This is achieved by incorporating alloying elements that form carbides, such as chromium and vanadium, which increase the hardness and wear resistance of the tool steel. 4. Toughness: While hardness and wear resistance are important, tool steel billets must also possess sufficient toughness to withstand the high impact forces generated during cutting. High toughness ensures that the cutting tools do not fracture or chip easily, even under severe cutting conditions. 5. Heat Resistance: Cutting tools are often exposed to high temperatures during operation, especially in high-speed cutting applications. Tool steel billets must have good heat resistance to prevent softening or deformation at elevated temperatures. This is achieved by adding alloying elements like molybdenum and tungsten, which contribute to the heat resistance properties of the tool steel. 6. Machinability: Tool steel billets should have good machinability to enable the production of complex cutting tool geometries with high precision. Proper selection of alloying elements and heat treatment processes can enhance the machinability of tool steel billets. It is important to note that the specific specifications for tool steel billets may vary depending on the specific cutting tool application, the material being cut, and the machining conditions. Therefore, it is crucial to consult with the tool steel manufacturer or supplier to determine the exact specifications required for a particular cutting tool application.

- Q: What is the role of steel billets in the manufacturing of tools and dies?

- Steel billets play a crucial role in the manufacturing of tools and dies as they serve as the raw material for shaping and forming these components. Billets are heated, forged, and machined to create the desired shape and strength required for tools and dies. The high-quality, durable nature of steel billets ensures that the resulting tools and dies possess the necessary hardness, toughness, and wear resistance to withstand the demanding conditions of their applications.

- Q: How are steel billets used in the production of building facades?

- Steel billets are used in the production of building facades as they serve as the raw material for manufacturing different components such as beams, columns, and plates. These billets are hot-rolled or forged into specific shapes and sizes, which are then used to create the structural framework of the facade. Additionally, steel billets are also used to create decorative elements and cladding panels that enhance the aesthetic appeal of the building exterior.

- Q: How are steel billets used in the production of aerospace components?

- Steel billets are used in the production of aerospace components as they serve as the starting material for the manufacturing process. Steel billets are essentially semi-finished steel forms that are hot-rolled or forged into specific shapes and sizes. In the aerospace industry, steel billets are typically used to produce critical components such as landing gear, engine components, structural parts, and fasteners. These billets are chosen for their superior strength, durability, and resistance to high temperatures and corrosive environments, which are crucial properties required for aerospace applications. The production of aerospace components using steel billets involves several steps. First, the billets are heated to a high temperature to make them malleable and easy to work with. They are then subjected to various forming processes such as forging, extrusion, or rolling, which shape them into the desired form. These processes allow for precise shaping and dimensional accuracy, ensuring that the components meet the required specifications and tolerances. After the initial shaping, the aerospace components are subjected to further processes such as heat treatment, machining, and surface finishing to enhance their mechanical properties and improve their surface quality. Heat treatment processes such as quenching and tempering are used to strengthen the steel and improve its hardness, toughness, and resistance to wear and fatigue. Machining processes are then employed to achieve the final shape, size, and surface finish of the components. Once the components are manufactured, they undergo rigorous quality control procedures to ensure they meet the stringent standards and regulations of the aerospace industry. This includes thorough inspections, non-destructive testing, and material analysis to verify their integrity, performance, and safety. In summary, steel billets are essential in the production of aerospace components as they provide a reliable and strong starting material. The versatility and excellent mechanical properties of steel make it a preferred choice in the aerospace industry, where reliability and safety are of utmost importance.

- Q: How do steel billets contribute to the chemical industry?

- Steel billets are a crucial raw material in the chemical industry as they are used in the production of various chemical equipment and machinery. These billets serve as a foundation for manufacturing components such as pipes, valves, tanks, and reactors, which are essential in carrying out chemical processes. Their strength, durability, and resistance to high temperatures make steel billets an ideal choice for constructing reliable and safe equipment used in the chemical industry.

Send your message to us

Prime square alloy steel billet 90mm Q235

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords