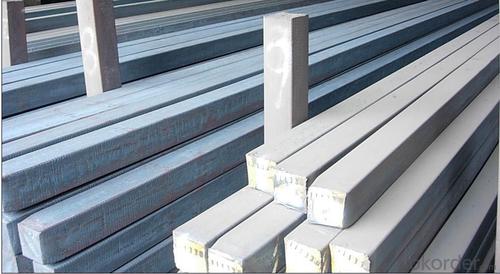

Prime square alloy steel billet 135mm Q235

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Structure of Prime square alloy steel billet 135mm Q235

Description of Prime square alloy steel billet 135mm Q235

Manufacture Progress:HRC-CRC-GALVANIZED-COLOR COATED

Application : Construction, electrical, transportation, steel plant, composite board plant, steel tile factory

Payment & Shipping Terms:T/T ,L/C, and FOB CHINA

Minimum Order Quantity: 25Tons

Packge Type: Moisture-proof paper inner,Steel outside,Bundle by steel rope.

Package in Container : Wood as a foot pad, wire rope reinforcement,PPGI steel coil tied together by steel rope.

Main Feature of Prime square alloy steel billet 135mm Q235

Uncoated CR steel sheet

With the features of in line with the international highest standards in demension and shape, excellent surface finish and properties, the products are mainly used in home appliance and automobile industries.

Galvanized steel sheet(include HDG and EG)

With the features of good corrosion resistance, the products are mainly used in automobile, home appliance, electronics, building and machinery manufacture industries, etc.

Precoated steel sheet

With the features of enviromental protection and good processablility, long lasting surface durability, rich in colors, the products are maily used in building, home appliance and furniture industries, etc.

Applications of Prime square alloy steel billet 135mm Q235

1) Excellent corrosion resistance: The zinc layer provides a good protection of Pre-painted Galvanizeed Steel Sheet.

2) High heat resistance: The reflective surface of the material aids in efficiently reflecting the sunlight away and in turn reducing the amount of heat transmitted. The thermal reflectivity converts into energy savings.

3) Aesthetics: Pre-Painted Galvanized steel sheet is available in plethora of patterns and multiple sizes as per the requirements that given by our customers.

4) Versatility: can be used in the various areas.

Specifications of Prime square alloy steel billet 135mm Q235

Product | Billet |

Material Grade | SGCC / SGCH / DX51D+AZ, etc |

Thickness | 0.6-3.0mm |

Width | 500-1500mm |

Tolerance | Thickness: +/-0.02mm , Width:+/-2mm |

Zinc-coating | Z30-150g/m2 |

Technique | Raw material: Hot rolled steel coil --> Cold rolled_>hot dipped galvalume |

Surface | Dried, Chromated, Unoiled |

Spangle | Regular spangle , small spangle, zero spangle |

ID | 508MM 610MM |

Coil weight | 1-25MT |

Export package | Cardboard inner sleeves, Waterproof paper, galvanized steel covered and steel strip packed |

FAQ of Prime square alloy steel billet 135mm Q235

We have organized several common questions for our clients,may help you sincerely:

1. How Can I Visit There?

Our company is located in Tianjin City, China, near Beijing. You can fly to Tianjin Airport Directly. All our clients, from home or aboard, are warmly welcome to visit us!

2. How Can I Get Some Sample?

We are honored to offer you sample.

3. Why choose CNBM?

we always fix steel produce in container well to make it safe arrive at destination port

we always provide best and professional forward service for our buyer

we always apply 14days free detention for our buyers container in destination

we provide one set After-sales service for our buyer

we provide China inland steel market price report

we help our buyer become number one in local market .

- Q: Can steel billets be coated for improved aesthetic appearance?

- Yes, steel billets can be coated with various materials such as paints, lacquers, or powder coatings to enhance their aesthetic appearance.

- Q: What are the main factors that affect the availability of steel billets?

- The main factors that affect the availability of steel billets include the demand and consumption patterns in the steel industry, the production capacity and efficiency of steel mills, fluctuations in raw material prices, government policies and regulations, and global economic conditions.

- Q: How are steel billets used in the production of automotive braking systems?

- Steel billets are used in the production of automotive braking systems as they serve as the raw material for manufacturing brake components such as discs, rotors, calipers, and brake pads. These billets are heated, shaped, and machined to create the necessary brake parts, which are then assembled and integrated into the braking system of vehicles.

- Q: Can steel billets be used in the production of appliances?

- Appliances can indeed utilize steel billets for their production. These semi-finished products are typically employed for subsequent processing into diverse forms and dimensions. In the context of appliances, steel billets can serve as the primary material for fabricating elements like frames, panels, and other structural components. Steel possesses remarkable versatility and durability, providing robustness, stability, and corrosion resistance, thereby rendering it appropriate for appliances requiring sturdy construction. Moreover, steel can be effortlessly molded and shaped to fulfill the distinct design requisites of various appliances, making it the preferred choice in the manufacturing procedure.

- Q: How are steel billets used in the production of reinforcing bars?

- Steel billets are an essential component in the production of reinforcing bars. These billets, which are semi-finished steel products, serve as the raw material for the manufacturing process. To produce reinforcing bars, the steel billets are heated to a specific temperature in a furnace. This heating process helps to improve the malleability of the steel, making it easier to shape and manipulate. Once the billets have reached the desired temperature, they are then passed through a series of rolling mills. These mills apply significant pressure to the billets, gradually reducing their size and shaping them into the required dimensions for reinforcing bars. The rolling process also helps to improve the mechanical properties of the steel, enhancing its strength and durability. After the rolling process is complete, the now elongated steel bars are cut into specific lengths according to the desired dimensions and requirements. These lengths are then allowed to cool, which helps to stabilize the steel and prevent any deformations. Finally, the reinforcing bars undergo a surface treatment process, such as hot-dip galvanization or epoxy coating, to provide corrosion resistance and improve their longevity. This treatment further enhances the performance and lifespan of the reinforcing bars, making them suitable for use in construction projects. In summary, steel billets are used as the starting material in the production of reinforcing bars. Through a series of heating, rolling, cutting, and surface treatment processes, the billets are transformed into high-strength steel bars that provide reinforcement to concrete structures.

- Q: How do steel billets contribute to the manufacturing of construction machinery?

- Steel billets play a crucial role in the manufacturing of construction machinery. These cylindrical or square bars of steel are the primary raw material used in the production of various components and parts for construction machinery. Firstly, steel billets are used to create the structural frame of construction machinery. The high strength and durability of steel make it an ideal material for ensuring the structural integrity of heavy machinery. Steel billets are shaped and welded together to form the sturdy frame, providing the necessary support and stability to the equipment. Additionally, steel billets are used to manufacture critical components such as gears, shafts, and axles. These components require high tensile strength and resistance to wear and tear, which can be achieved using steel billets. By machining, forging, or casting steel billets into the desired shape, these components can withstand the heavy loads and harsh operating conditions in the construction industry. Moreover, steel billets are used to produce buckets, blades, and cutting edges for construction machinery. These components are subjected to extreme forces and abrasion during excavation, grading, and other construction activities. Steel billets, with their excellent hardness and toughness, ensure that these components can withstand the demanding conditions and perform effectively. Furthermore, steel billets are essential in the production of hydraulic cylinders and pistons. These components are responsible for generating the force required for lifting, pushing, and pulling heavy loads in construction machinery. Steel billets are machined and shaped to create the cylinder bodies and pistons, ensuring the necessary strength and precision for efficient hydraulic operations. In summary, steel billets are indispensable in the manufacturing of construction machinery. They provide the strength, durability, and wear resistance required for the various components and parts of construction equipment. Steel billets contribute to the overall performance and reliability of construction machinery, ensuring that they can withstand the demanding conditions and heavy workloads encountered in the construction industry.

- Q: What are the main surface finishes available for steel billets?

- The main surface finishes available for steel billets include hot rolled, cold rolled, and coated finishes.

- Q: What are the different surface treatments available for steel billets?

- There are several surface treatments available for steel billets, including shot blasting, pickling, phosphating, and galvanizing. Shot blasting involves propelling abrasive materials at high speeds to remove rust and scale from the surface. Pickling involves immersing the billets in an acid solution to remove oxide layers and impurities. Phosphating applies a layer of phosphate coating to enhance corrosion resistance and improve paint adhesion. Galvanizing involves applying a zinc coating to protect the surface from corrosion.

- Q: What are the different types of surface coating methods used for steel billets?

- There are several types of surface coating methods used for steel billets, including galvanizing, electroplating, powder coating, and painting. Galvanizing involves applying a layer of zinc to the surface of the billets to provide corrosion resistance. Electroplating uses an electrical current to deposit a thin layer of metal onto the steel surface, enhancing its appearance and protecting it from corrosion. Powder coating involves applying a dry powder to the billets, which is then heated to form a protective layer. Painting is another common method, where a liquid paint is applied to the billets to provide both protection and aesthetic appeal.

- Q: What does the billet of the steel plant refer to?And steel what is the difference?

- Billet is the product of molten steel made by steelmaking furnace. After casting, the billet can be divided into two kinds: casting blank and continuous casting billet. At present, the casting process has been basically eliminatedRefers to the use of reinforced and prestressed concrete with steel reinforced concrete, the cross section is circular, sometimes square with rounded corners. Including round bars, ribbed steel bars, steel torsion bar.

Send your message to us

Prime square alloy steel billet 135mm Q235

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords