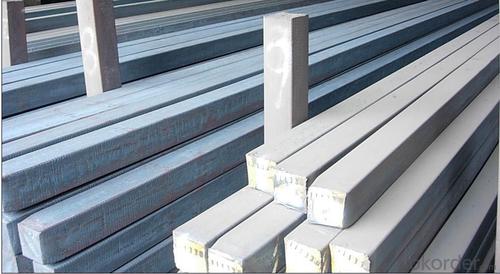

Prime square alloy steel billet 125mm Q235

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Structure of Prime square alloy steel billet 125mm Q235

Description of Prime square alloy steel billet 125mm Q235

1. Prepainted steel coil is coated with organic layer, which provides higher anti-corrosion property and a longer lifespan than that of galvanized or galvalume steel sheets.

2. The base metals for prepainted steel coil consist of cold rolled, HDGI Steel, electro-galvanized and hot-dip alu-zinc coated steel. The finish coats of prepainted steel coil can be classified into groups as follows: polyester, silicon modified polyesters, polyvinylidene fluoride, high-durability polyester, etc.

3. The production process has evolved from one-coating-and-one-baking to double-coating-and-double-baking, and even three-coating-and-three-baking.

4. The color of the prepainted steel coil has a very wide selection, like orange, cream-colored, dark sky blue, sea blue, bright red, brick red, ivory white, porcelain blue, etc.

5. The prepainted steel coils can also be classified into groups by their surface textures, namely regular prepainted sheets, embossed sheets and printed sheets.

Main Feature of Prime square alloy steel billet 125mm Q235

Uncoated CR steel sheet

With the features of in line with the international highest standards in demension and shape, excellent surface finish and properties, the products are mainly used in home appliance and automobile industries.

Galvanized steel sheet(include HDG and EG)

With the features of good corrosion resistance, the products are mainly used in automobile, home appliance, electronics, building and machinery manufacture industries, etc.

Precoated steel sheet

With the features of enviromental protection and good processablility, long lasting surface durability, rich in colors, the products are maily used in building, home appliance and furniture industries, etc.

Applications of Prime square alloy steel billet 125mm Q235

Manufacture Progress:HRC-CRC-GALVANIZED-COLOR COATED

Application : Construction, electrical, transportation, steel plant, composite board plant, steel tile factory

Payment & Shipping Terms:T/T ,L/C, and FOB CHINA

Minimum Order Quantity: 25Tons

Packge Type: Moisture-proof paper inner,Steel outside,Bundle by steel rope.

Package in Container : Wood as a foot pad, wire rope reinforcement,PPGI steel coil tied together by steel rope.

Specifications of Prime square alloy steel billet 125mm Q235

Product | Billet |

Material Grade | SGCC / SGCH / DX51D+AZ, etc |

Thickness | 0.6-3.0mm |

Width | 500-1500mm |

Tolerance | Thickness: +/-0.02mm , Width:+/-2mm |

Zinc-coating | Z30-150g/m2 |

Technique | Raw material: Hot rolled steel coil --> Cold rolled_>hot dipped galvalume |

Surface | Dried, Chromated, Unoiled |

Spangle | Regular spangle , small spangle, zero spangle |

ID | 508MM 610MM |

Coil weight | 1-25MT |

Export package | Cardboard inner sleeves, Waterproof paper, galvanized steel covered and steel strip packed |

FAQ of Prime square alloy steel billet 125mm Q235

We have organized several common questions for our clients,may help you sincerely:

1. How Can I Visit There?

Our company is located in Tianjin City, China, near Beijing. You can fly to Tianjin Airport Directly. All our clients, from home or aboard, are warmly welcome to visit us!

2. How Can I Get Some Sample?

We are honored to offer you sample.

3. Why choose CNBM?

we always fix steel produce in container well to make it safe arrive at destination port

we always provide best and professional forward service for our buyer

we always apply 14days free detention for our buyers container in destination

we provide one set After-sales service for our buyer

we provide China inland steel market price report

we help our buyer become number one in local market .

- Q: Can steel billets be used in the production of medical equipment?

- Certainly, medical equipment can utilize steel billets. Renowned for its robustness, longevity, and resistance to deterioration, steel proves to be an optimal substance for fabricating diverse medical apparatus. Steel billets, the preliminary intermediate product in steel production, can undergo additional processing and molding to form precise components or parts indispensable for medical equipment. Such components encompass surgical instruments, implants, orthopedic devices, needles, and other medical implements. The mechanical attributes of steel and its capacity to endure sterilization procedures render it a fitting preference for manufacturing dependable and secure medical equipment.

- Q: How are steel billets used in the manufacturing of oil and gas components?

- Steel billets play a crucial role in the manufacturing process of oil and gas components. These billets serve as essential materials and are created through a process known as casting. In this process, molten steel is poured into a mold and allowed to solidify into a rectangular shape, resulting in semi-finished products. Once formed, steel billets are utilized in various ways to produce components for the oil and gas industry. One common application involves their use in the production of pipes, which are vital for transporting oil and gas from reservoirs to processing facilities or end-users. Depending on project requirements, steel billets can be further processed to create seamless or welded pipes. Aside from pipes, steel billets are also employed in the manufacturing of other important oil and gas components such as valves, fittings, flanges, and pressure vessels. These components are crucial for ensuring the safe and efficient operation of oil and gas facilities, as they facilitate proper flow control, connection, and containment of fluids under high pressures and temperatures. The utilization of steel billets in the manufacturing process of oil and gas components offers several advantages. Firstly, steel is widely recognized for its strength, durability, and resistance to corrosion, making it highly suitable for the harsh and demanding operating conditions of the industry. Additionally, steel billets allow for flexibility in terms of size, shape, and composition, enabling manufacturers to produce components tailored to meet specific project requirements. In conclusion, steel billets play a critical role in the production of oil and gas components. They provide the necessary strength, durability, and versatility required for the safe and efficient operation of the industry.

- Q: Are steel billets magnetic?

- Yes, steel billets are magnetic. Steel is an alloy primarily composed of iron, which is a ferromagnetic material. This means that it can be magnetized and therefore exhibits magnetic properties. Steel billets, being solid blocks or bars of steel, retain the magnetic properties of the material they are made from.

- Q: What are the different types of steel alloys used for manufacturing steel billets?

- There are various types of steel alloys used for manufacturing steel billets, including carbon steel, alloy steel, and stainless steel. Carbon steel is the most commonly used alloy and is known for its strength and durability. Alloy steel contains additional elements such as nickel, chromium, or manganese, which enhance its properties and make it suitable for specific applications. Stainless steel, on the other hand, is corrosion-resistant and often used in industries requiring high resistance to rust and staining.

- Q: How are steel billets used in the production of power transmission equipment?

- Steel billets are used in the production of power transmission equipment as they are heated and shaped into various components such as gears, shafts, and couplings. These billets provide the necessary strength and durability required for these equipment to handle high power loads and transmit energy efficiently.

- Q: How are steel billets used in the production of structural components?

- Steel billets are used in the production of structural components by being heated and molded into desired shapes such as beams, columns, and plates. These billets serve as the starting material, which is then further processed through rolling, forging, or extrusion to create strong and durable structural components used in various industries such as construction, automotive, and aerospace.

- Q: Can steel billets be used for making decorative items?

- Certainly, decorative items can be made using steel billets. Steel, being a versatile and sturdy material, can be molded and shaped into various forms. Skilled craftsmen can transform steel billets into stunning decorative pieces like sculptures, furniture, wall art, and other ornamental items. Moreover, steel's durability and longevity make it an excellent choice for decorative items that need to endure over time. Furthermore, steel can be finished in different ways, such as polishing, painting, or incorporating other decorative elements, which further enhance its aesthetic appeal. Therefore, steel billets present enormous potential for creating one-of-a-kind and visually captivating decorative items.

- Q: What are the factors that affect the mechanical properties of steel billets?

- There are several factors that affect the mechanical properties of steel billets. 1. Chemical composition: The chemical composition of steel, including the levels of carbon, manganese, silicon, and other alloying elements, plays a significant role in determining its mechanical properties. These elements affect the strength, hardness, and ductility of the steel billets. 2. Heat treatment: The heat treatment process, including the temperature and duration of heating and cooling, can greatly influence the mechanical properties of steel billets. Heat treatment techniques such as annealing, quenching, and tempering can be used to enhance the hardness, toughness, and overall strength of the steel. 3. Microstructure: The microstructure of steel, which is determined by factors such as cooling rate and alloying elements, greatly influences its mechanical properties. The presence of different phases, such as ferrite, pearlite, and martensite, affects the strength, ductility, and toughness of the steel billets. 4. Grain size: The size and distribution of grains in the steel billets can impact their mechanical properties. Finer grain sizes are generally associated with improved strength and toughness, while larger grain sizes may result in reduced mechanical properties. 5. Processing conditions: The processing conditions during the production of steel billets, such as the temperature and rate of deformation, can affect their mechanical properties. Factors such as rolling, forging, and extrusion can influence the grain structure and overall mechanical behavior of the steel. 6. Surface condition: The surface condition of steel billets, including the presence of defects such as cracks, voids, or surface contamination, can have a significant impact on their mechanical properties. Surface defects can act as stress concentration points and reduce the overall strength and integrity of the steel. 7. Environmental factors: Environmental conditions, such as temperature, humidity, and exposure to corrosive substances, can affect the mechanical properties of steel billets. Corrosion can lead to reduced strength and structural integrity, while high temperatures can cause softening or thermal degradation of the steel. It is important to consider these factors when designing and manufacturing steel billets to ensure that the desired mechanical properties are achieved for specific applications.

- Q: How are steel billets used in the manufacturing of structural components?

- Steel billets are used in the manufacturing of structural components as they are the starting material for various shaping and forming processes. These billets are heated and then worked upon through techniques like rolling, forging, or extrusion to produce different structural shapes such as beams, columns, or plates. This ensures that the components have the necessary strength, durability, and dimensional accuracy required for construction purposes.

- Q: What are the different types of surface finish inspection methods for steel billets?

- There are several different types of surface finish inspection methods that can be used for steel billets. These methods are crucial in determining the quality and suitability of the billets for further processing or use. Some of the common surface finish inspection methods for steel billets include: 1. Visual inspection: This is a basic method where the surface of the billet is visually examined for any irregularities, such as cracks, pits, scratches, or any other surface imperfections. It is a quick and cost-effective method but may not be able to detect subtle defects. 2. Magnetic particle inspection: This method involves magnetizing the surface of the billet and applying fine iron particles on it. Any surface cracks or defects will cause a leakage of magnetic field, attracting the iron particles and making them visible under appropriate lighting conditions. 3. Dye penetrant inspection: In this method, a liquid dye is applied to the surface of the billet. The dye penetrates into any surface cracks or defects, and after a certain period, excess dye is removed. A developer is then applied, which draws out the dye from the cracks and defects, making them visible. 4. Ultrasonic testing: This method utilizes high-frequency sound waves that are transmitted through the steel billet. The waves are reflected back when they encounter any surface irregularities, such as cracks or voids. By analyzing the time taken for the waves to return, the size and depth of the defects can be determined. 5. Eddy current testing: This non-destructive testing method uses electromagnetic induction to detect surface defects. An alternating current is passed through a coil, creating a magnetic field. When the coil is near the surface of the billet, any defects will disrupt the magnetic field, causing a change in the electrical impedance. This change is measured and analyzed to identify surface defects. Each of these inspection methods has its advantages and limitations, and the choice of method depends on the specific requirements, the size and shape of the billet, and the level of accuracy desired. By employing these surface finish inspection methods, manufacturers can ensure the quality and reliability of the steel billets before they are further processed or used in various applications.

Send your message to us

Prime square alloy steel billet 125mm Q235

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords