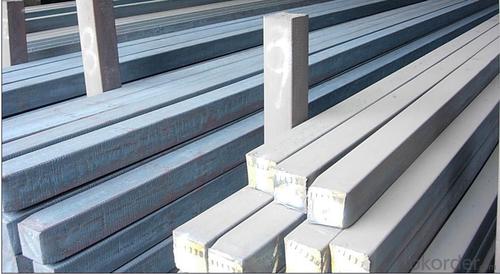

Prime quality square alloy steel billet 125mm Q235

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Structure of Prime quality square alloy steel billet 125mm Q235

Description of Prime quality square alloy steel billet 125mm Q235

1. Prepainted steel coil is coated with organic layer, which provides higher anti-corrosion property and a longer lifespan than that of galvanized or galvalume steel sheets.

2. The base metals for prepainted steel coil consist of cold rolled, HDGI Steel, electro-galvanized and hot-dip alu-zinc coated steel. The finish coats of prepainted steel coil can be classified into groups as follows: polyester, silicon modified polyesters, polyvinylidene fluoride, high-durability polyester, etc.

3. The production process has evolved from one-coating-and-one-baking to double-coating-and-double-baking, and even three-coating-and-three-baking.

4. The color of the prepainted steel coil has a very wide selection, like orange, cream-colored, dark sky blue, sea blue, bright red, brick red, ivory white, porcelain blue, etc.

5. The prepainted steel coils can also be classified into groups by their surface textures, namely regular prepainted sheets, embossed sheets and printed sheets.

Main Feature of Prime quality square alloy steel billet 125mm Q235

Uncoated CR steel sheet

With the features of in line with the international highest standards in demension and shape, excellent surface finish and properties, the products are mainly used in home appliance and automobile industries.

Galvanized steel sheet(include HDG and EG)

With the features of good corrosion resistance, the products are mainly used in automobile, home appliance, electronics, building and machinery manufacture industries, etc.

Precoated steel sheet

With the features of enviromental protection and good processablility, long lasting surface durability, rich in colors, the products are maily used in building, home appliance and furniture industries, etc.

Applications of Prime quality square alloy steel billet 125mm Q235

Construction

Manufacture anticorrosion, industrial and civil architecture roof boarding, roof grille

Light industries

Home appliance's case, civil chimney, kitchen utensils

Auto industry

Corrosion resistant parts of cars

Agriculture

Food storage, meat and aquatic products' freezing and processing equipment

Commerce

Equipments to store and transport materials, and packing implements

Specifications of Prime quality square alloy steel billet 125mm Q235

Product | Prime quality square alloy steel billet 125mm Q235 |

Material Grade | SGCC / SGCH / DX51D+AZ, etc |

Thickness | 0.6-3.0mm |

Width | 500-1500mm |

Tolerance | Thickness: +/-0.02mm , Width:+/-2mm |

Zinc-coating | Z30-150g/m2 |

Technique | Raw material: Hot rolled steel coil --> Cold rolled_>hot dipped galvalume |

Surface | Dried, Chromated, Unoiled |

Spangle | Regular spangle , small spangle, zero spangle |

ID | 508MM 610MM |

Coil weight | 1-25MT |

Export package | Cardboard inner sleeves, Waterproof paper, galvanized steel covered and steel strip packed |

FAQ of Prime quality square alloy steel billet 125mm Q235

We have organized several common questions for our clients,may help you sincerely:

1. How Can I Visit There?

Our company is located in Tianjin City, China, near Beijing. You can fly to Tianjin Airport Directly. All our clients, from home or aboard, are warmly welcome to visit us!

2. How Can I Get Some Sample?

We are honored to offer you sample.

3. Why choose CNBM?

Our delivery time about 15-20days for standard sizes, if you have other requirements like hardness, quanity and width ,it is about 20-40days. But don't worry we also try our best for the delivery time ,because time longer and our cost is higher.

- Q: How are steel billets used in the manufacturing of tools and equipment?

- Steel billets are a vital raw material utilized in the production of tools and equipment. These billets are semi-finished metal forms, typically rectangular or square, which undergo further processing to manufacture a wide range of products. To commence, steel billets are heated and then subjected to a process known as hot rolling. This process involves passing the billets through a series of rollers, gradually reducing their thickness and shaping them into desired forms. The resulting forms can include bars, rods, sheets, or even more intricate shapes, depending on the specific requirements for the tool or equipment being produced. Once the desired shape is achieved, the steel billets undergo additional processing through various techniques such as forging, machining, and heat treatment. Forging entails applying pressure to shape the billets into specific tool components, while machining is used to refine the shape and dimensions of the parts. Heat treatment is employed to enhance the mechanical properties of the steel, increasing its strength, durability, and resistance to wear and tear. The resultant steel components are then assembled and integrated into the production of tools and equipment. These encompass a diverse range of products, including wrenches, hammers, drills, cutting tools, industrial machinery, and even large-scale equipment used in sectors such as construction and manufacturing. Steel billets are favored for tool and equipment production due to their exceptional mechanical properties. Steel is renowned for its high strength, toughness, and durability, making it an ideal material for applications requiring resistance to heavy loads, impacts, and wear. Moreover, steel can be easily machined, welded, and formed into various shapes, enabling manufacturers to create tools and equipment with intricate designs and precise dimensions. In conclusion, steel billets play a pivotal role in the production of tools and equipment. Through the processes of hot rolling, forging, machining, and heat treatment, steel billets are transformed into high-quality components that serve as the foundation for various tools and equipment. The versatility and superior mechanical properties of steel render it an indispensable material in the manufacturing industry.

- Q: What are the common shapes of steel billets?

- Steel billets can come in a variety of shapes, depending on their intended use and manufacturing process. Some of the common shapes of steel billets include square, rectangular, round, and hexagonal. Square billets are often used for applications requiring stability and strength, such as construction materials and machinery parts. Rectangular billets, with their elongated shape, are commonly used for structural components in construction and engineering projects. Round billets are often used for manufacturing pipes, tubes, and other cylindrical objects. Hexagonal billets, with their six-sided shape, are frequently used in the production of hex nuts, bolts, and other fasteners. These different shapes provide versatility in meeting various industry requirements and applications.

- Q: What are the different types of tests conducted on steel billets?

- There are several types of tests conducted on steel billets, including visual inspection, dimensional inspection, chemical composition analysis, mechanical testing, ultrasonic testing, and magnetic particle inspection. These tests are crucial to ensure the quality and integrity of the steel billets before they are further processed and used in various applications.

- Q: What are the common surface defects in steel billets during cooling?

- During the cooling process of steel billets, several common surface defects can occur. These defects can arise due to various factors such as improper handling, inadequate cooling techniques, or material impurities. Some of the most common surface defects in steel billets during cooling include: 1. Scale Formation: Scale is a thin layer of oxides that forms on the surface of the steel due to exposure to air during the cooling process. It can result in a rough and uneven surface, reducing the overall quality of the billet. 2. Cracks: Cracks can occur during cooling due to the thermal stresses induced in the steel. These cracks can be longitudinal, transverse, or even intergranular, affecting the structural integrity of the billet. 3. Lamination: Lamination defects occur when layers or sheets of steel separate from each other due to inadequate bonding during the cooling process. This can lead to weak spots in the billet and reduce its overall strength. 4. Shrinkage Cavities: Shrinkage cavities, also known as shrinkage porosity, occur when the steel solidifies and contracts during cooling, resulting in voids or cavities in the billet's surface. These cavities can weaken the steel and compromise its mechanical properties. 5. Surface Roughness: Inadequate cooling techniques can lead to uneven cooling and rapid solidification, resulting in a rough and uneven surface texture on the billet. This defect can affect the billet's surface finish and subsequent processing. 6. Decarburization: Decarburization is the loss of carbon content from the surface of the billet due to exposure to high temperatures and oxygen during the cooling process. This can lead to reduced hardness and strength in the affected areas. To minimize these surface defects, proper cooling techniques, including controlled cooling rates, use of protective coatings, and handling practices, should be implemented. Regular inspection and quality control measures are also essential to identify and rectify any defects during the cooling process and ensure the production of high-quality steel billets.

- Q: How do steel billets contribute to the manufacturing of household appliances?

- Steel billets play a crucial role in the manufacturing of household appliances. These billets serve as the raw material for the production of various components and structures used in household appliances. Firstly, steel billets are used to manufacture the frames and structures of appliances such as refrigerators, washing machines, and dishwashers. The high strength and durability of steel make it an ideal choice for these applications, ensuring that the appliances can withstand the constant use and heavy loads they encounter. Secondly, steel billets are used to produce the inner and outer panels of household appliances. These panels require a material that is strong, resistant to corrosion, and aesthetically pleasing. Steel fits these criteria perfectly, providing a sleek and durable surface that can be easily cleaned and maintained. Additionally, steel billets are used to create various components within household appliances, including heating elements, motors, and electrical parts. Steel's excellent thermal conductivity and electrical properties make it a suitable material for these critical components, ensuring efficient operation and reliable performance. Furthermore, steel billets contribute to the overall safety of household appliances. Steel is a fire-resistant material, reducing the risk of accidents caused by overheating or electrical malfunctions. Its strength and stability also play a role in preventing structural failures that could lead to accidents or injuries. In summary, steel billets are essential in the manufacturing of household appliances due to their strength, durability, corrosion resistance, and thermal/electrical properties. By providing the necessary raw material, steel billets enable the production of robust structures, aesthetic panels, critical components, and safe appliances that meet the demands and expectations of consumers.

- Q: How are steel billets used in the production of automotive parts?

- Steel billets are commonly used in the production of automotive parts as they serve as the raw material for forging, rolling, or extruding processes. These billets are heated and shaped into various forms such as rods, bars, or sheets to create components like engine parts, suspension systems, and body frames. The high strength and durability of steel make it an ideal choice for manufacturing automotive parts, ensuring safety and performance in vehicles.

- Q: What are the key factors driving the demand for steel billets?

- The demand for steel billets is influenced by several key factors. Firstly, the construction industry plays a crucial role in driving this demand. Steel is widely utilized in construction projects for various purposes, including structural framing, reinforcement, and support systems. With the continuous growth of urbanization and increasing infrastructure projects, the demand for steel billets also rises. Additionally, the automotive industry significantly impacts the demand for steel billets. Steel is an essential material in the manufacturing of automobiles, such as car bodies, chassis, and engine components. As the global automotive industry expands and consumer demand for vehicles increases, the demand for steel billets also rises accordingly. Moreover, the energy sector contributes to the demand for steel billets, particularly in the production of oil and gas pipelines. Steel billets are used in the manufacturing of seamless pipes, which are vital for the transportation of oil and gas over long distances. As the demand for energy continues to grow, there is a corresponding need for steel billets to support pipeline construction. Furthermore, the manufacturing and machinery industries heavily rely on steel billets. Steel is a fundamental material used in various manufacturing processes, from industrial machinery to consumer products. As these industries grow and evolve, the demand for steel billets remains steady. Lastly, the demand for steel billets is significantly influenced by global economic growth and industrialization in emerging markets. Countries with rapidly developing economies, such as China and India, are major consumers of steel billets as they undergo massive infrastructure projects and industrial expansion. In conclusion, the demand for steel billets is primarily driven by the construction industry, automotive sector, energy sector, manufacturing industry, and global economic growth. These factors collectively contribute to the sustained and growing demand for steel billets in the market.

- Q: How are steel billets inspected for surface cleanliness?

- Steel billets are inspected for surface cleanliness through visual inspection, where trained inspectors carefully examine the billets for any visible dirt, oxide scale, or other contaminants. Additionally, surface cleanliness can also be tested using methods like magnetic particle testing or ultrasonic testing to detect any hidden defects or impurities.

- Q: What are the different surface treatments applied to steel billets?

- Depending on the desired outcome and application, steel billets can undergo several different surface treatments. Some common treatments include: 1. Shot Blasting: This method involves propelling small metal or mineral particles onto the steel billet surface at high speeds. Shot blasting effectively removes surface impurities like rust or scale, resulting in a clean and even surface. 2. Pickling: Pickling is a chemical treatment that submerges the steel billets in an acid solution, usually hydrochloric or sulfuric acid. This process eliminates oxide layers or scale from the billet surface, leaving it clean and smooth. 3. Phosphating: Phosphating is a chemical conversion coating process that involves immersing the steel billets in a solution containing phosphate salts. This treatment forms a thin, corrosion-resistant phosphate film on the surface. 4. Galvanizing: Galvanizing is a widely used surface treatment for steel billets, where a layer of zinc is applied. This process provides excellent corrosion protection and enhances durability. 5. Painting: Another common surface treatment is painting, where a layer of paint is applied to the steel billet surface. This not only enhances aesthetic appeal but also provides additional corrosion protection. 6. Electroplating: Electroplating involves depositing a thin layer of metal, such as chromium or nickel, onto the steel billet surface using an electrical current. This treatment improves appearance, corrosion resistance, and wear resistance. It is important to consider factors like intended use, environmental conditions, and cost when selecting a surface treatment for steel billets. Each treatment offers specific benefits, so choosing the most suitable option ensures optimal performance and longevity.

- Q: What are the different grades of steel billets?

- There are several different grades of steel billets, each with its own specific properties and applications. Some of the commonly used grades include: 1. Mild Steel Billets: These are low carbon steel billets that are often used in general construction and engineering applications. They have a relatively low tensile strength and are easily weldable and formable. 2. Carbon Steel Billets: These contain a higher carbon content than mild steel billets, giving them increased strength and hardness. They are commonly used in the manufacturing of automotive parts, machinery, and tools. 3. Alloy Steel Billets: These are steel billets that have been alloyed with other elements such as chromium, nickel, or molybdenum to improve specific properties. Alloy steel billets offer enhanced strength, toughness, and corrosion resistance, making them suitable for applications in the aerospace, defense, and oil and gas industries. 4. Stainless Steel Billets: These billets contain high levels of chromium and nickel, which provide excellent corrosion resistance and durability. Stainless steel billets are commonly used in the production of kitchen appliances, cutlery, and medical equipment. 5. High-Speed Steel Billets: These billets are alloyed with tungsten, molybdenum, or vanadium to create a steel with exceptional hardness and heat resistance. High-speed steel billets are primarily used in the production of cutting tools such as drill bits and saw blades. It is important to note that the specific grades of steel billets can vary depending on the manufacturing standards and region. These grades are classified based on their chemical composition, mechanical properties, and intended applications, ensuring that the right steel billet is selected for the desired end use.

Send your message to us

Prime quality square alloy steel billet 125mm Q235

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords