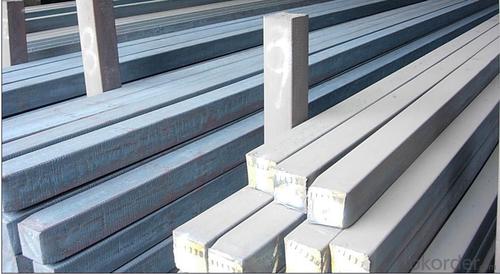

Prime quality square alloy steel billet 120mm Q235

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Structure of Prime quality square alloy steel billet 120mm Q235

Description of Prime quality square alloy steel billet 120mm Q235

1. Prepainted steel coil is coated with organic layer, which provides higher anti-corrosion property and a longer lifespan than that of galvanized or galvalume steel sheets.

2. The base metals for prepainted steel coil consist of cold rolled, HDGI Steel, electro-galvanized and hot-dip alu-zinc coated steel. The finish coats of prepainted steel coil can be classified into groups as follows: polyester, silicon modified polyesters, polyvinylidene fluoride, high-durability polyester, etc.

3. The production process has evolved from one-coating-and-one-baking to double-coating-and-double-baking, and even three-coating-and-three-baking.

4. The color of the prepainted steel coil has a very wide selection, like orange, cream-colored, dark sky blue, sea blue, bright red, brick red, ivory white, porcelain blue, etc.

5. The prepainted steel coils can also be classified into groups by their surface textures, namely regular prepainted sheets, embossed sheets and printed sheets.

Main Feature of Prime quality square alloy steel billet 120mm Q235

Uncoated CR steel sheet

With the features of in line with the international highest standards in demension and shape, excellent surface finish and properties, the products are mainly used in home appliance and automobile industries.

Galvanized steel sheet(include HDG and EG)

With the features of good corrosion resistance, the products are mainly used in automobile, home appliance, electronics, building and machinery manufacture industries, etc.

Precoated steel sheet

With the features of enviromental protection and good processablility, long lasting surface durability, rich in colors, the products are maily used in building, home appliance and furniture industries, etc.

Applications of Prime quality square alloy steel billet 120mm Q235

Construction

Manufacture anticorrosion, industrial and civil architecture roof boarding, roof grille

Light industries

Home appliance's case, civil chimney, kitchen utensils

Auto industry

Corrosion resistant parts of cars

Agriculture

Food storage, meat and aquatic products' freezing and processing equipment

Commerce

Equipments to store and transport materials, and packing implements

Specifications of Prime quality square alloy steel billet 120mm Q235

Product | Prime quality square alloy steel billet 120mm Q235 |

Material Grade | SGCC / SGCH / DX51D+AZ, etc |

Thickness | 0.6-3.0mm |

Width | 500-1500mm |

Tolerance | Thickness: +/-0.02mm , Width:+/-2mm |

Zinc-coating | Z30-150g/m2 |

Technique | Raw material: Hot rolled steel coil --> Cold rolled_>hot dipped galvalume |

Surface | Dried, Chromated, Unoiled |

Spangle | Regular spangle , small spangle, zero spangle |

ID | 508MM 610MM |

Coil weight | 1-25MT |

Export package | Cardboard inner sleeves, Waterproof paper, galvanized steel covered and steel strip packed |

FAQ of Prime quality square alloy steel billet 120mm Q235

We have organized several common questions for our clients,may help you sincerely:

1. How Can I Visit There?

Our company is located in Tianjin City, China, near Beijing. You can fly to Tianjin Airport Directly. All our clients, from home or aboard, are warmly welcome to visit us!

2. How Can I Get Some Sample?

We are honored to offer you sample.

3. Why choose CNBM?

Our delivery time about 15-20days for standard sizes, if you have other requirements like hardness, quanity and width ,it is about 20-40days. But don't worry we also try our best for the delivery time ,because time longer and our cost is higher.

- Q: Can steel billets be used in the production of oil and gas equipment?

- Yes, steel billets can be used in the production of oil and gas equipment. Steel billets are commonly used as the raw material in the manufacturing process of various oil and gas equipment such as pipelines, valves, and drilling equipment. The high strength and durability of steel make it suitable for the challenging conditions and demands of the oil and gas industry.

- Q: Can steel billets be painted or coated for decorative purposes?

- Yes, steel billets can be painted or coated for decorative purposes. The surface of steel billets can be prepared and treated to ensure proper adhesion of paint or coating, allowing for customization and enhancing their appearance for decorative applications.

- Q: How is the quality of steel billets determined?

- The quality of steel billets is determined through various factors including chemical composition, physical properties, and visual inspection. Chemical composition analysis involves measuring the levels of different elements present in the billets such as carbon, manganese, and sulfur, as well as checking for any impurities. Physical properties such as tensile strength, hardness, and toughness are tested to ensure the billets meet the required specifications. Visual inspection is also performed to identify any defects like cracks, surface abnormalities, or unevenness. Combining these assessments helps determine the overall quality of steel billets.

- Q: How do steel billets contribute to the manufacturing of marine equipment?

- Steel billets are an essential raw material in the manufacturing of marine equipment. They serve as the starting point for various processes such as rolling, forging, and machining, which shape the billets into the desired components. These components, made from high-quality steel, provide strength, durability, and corrosion resistance necessary for marine equipment, ensuring their safe and reliable operation in challenging maritime environments.

- Q: What is the shelf life of a steel billet?

- The durability of a steel billet can vary based on various factors. In order to prevent corrosion and uphold their quality, steel billets are typically stored in controlled environments. With proper storage, steel billets can remain usable for several years. However, it is essential to acknowledge that the shelf life can be influenced by factors such as humidity levels, exposure to moisture or chemicals, and the specific type of steel employed. Consequently, it is crucial to adhere to the storage guidelines provided by manufacturers to guarantee an extended shelf life for steel billets. Regular inspections and maintenance can also aid in identifying any potential issues that may impact the durability of the billets.

- Q: Can steel billets be used for making hand tools?

- Yes, steel billets can be used for making hand tools. Steel billets are the initial form of steel that can be shaped and processed into various products, including hand tools. The billets can be heated, forged, and machined to create durable and reliable hand tools that can withstand the rigors of daily use.

- Q: What are the market trends and growth prospects for steel billets?

- The market trends for steel billets indicate steady growth prospects. With the increasing demand for steel in various sectors such as construction, automotive, and infrastructure, the demand for steel billets is expected to rise. Additionally, the growing focus on sustainable and eco-friendly construction materials is likely to drive the market further. Furthermore, the expanding urbanization and industrialization in emerging economies present significant growth opportunities for the steel billets market. Overall, the market for steel billets is expected to experience positive growth in the coming years.

- Q: How are steel billets tested for mechanical properties?

- Various methods are employed to test the mechanical properties of steel billets in order to verify their quality and suitability for specific applications. One commonly used method is the tensile test, which involves extracting a small sample from the billet and subjecting it to an increasing tensile force until it breaks. This test aids in determining crucial mechanical properties such as ultimate tensile strength, yield strength, and elongation. Another approach utilized is the hardness test, which assesses the billet's surface resistance to indentation. This test provides information regarding the billet's hardness, which is essential for evaluating its ability to withstand wear and deformation. Moreover, the impact test is performed to evaluate the billet's toughness and capacity to absorb energy. This entails striking a standardized sample with a pendulum and measuring the energy absorbed during fracture. The impact test is particularly significant for applications where the steel billet is exposed to sudden loads or impacts. To evaluate the billet's ability to resist deformation, the compression test is employed. In this test, the billet is subjected to a compressive force until it deforms or breaks. The results obtained from this test assist in determining the billet's compressive strength and deformation characteristics. Additionally, non-destructive testing methods such as ultrasonic testing and magnetic particle inspection are utilized to identify any internal defects or irregularities in the billet. These methods involve the use of specialized equipment to examine the billet's internal structure and detect any flaws that may compromise its mechanical properties. In conclusion, steel billets undergo a comprehensive range of tests to ensure that their mechanical properties meet the necessary standards. These tests are crucial in guaranteeing the quality and dependability of the billets, enabling their use in various industries including construction, automotive, and manufacturing.

- Q: What is the size and shape of steel billets?

- Steel billets come in various sizes and shapes, depending on the specific requirements of the manufacturing process. Typically, steel billets are rectangular or square in shape, with dimensions ranging from a few inches to several feet in length, width, and height. The exact size and shape of steel billets are determined by factors such as the type of steel being produced and the intended use of the billets in subsequent manufacturing processes.

- Q: What are the main challenges in the handling of steel billets during production?

- The handling of steel billets during production presents several challenges that need to be overcome for a smooth and efficient manufacturing process. One of the main challenges is the weight and size of the steel billets. Steel billets can be quite heavy, ranging from a few hundred kilograms to several tons, depending on their dimensions. This poses difficulties in terms of lifting and moving them within the production facility. Specialized equipment such as cranes and forklifts are required to handle these heavy loads safely. Another challenge is the potential for damage to the steel billets during handling. Steel billets are typically transported and stored in stacks or bundles. Improper handling techniques or insufficient protection can lead to deformation, scratches, or even breakage of the billets. These damages can affect the quality of the final product, leading to increased scrap rates and production costs. Additionally, maintaining precise temperature control is crucial during the handling of steel billets. Steel is sensitive to temperature changes, and the billets need to be kept within specific temperature ranges to avoid distortion or metallurgical issues. Special care must be taken when transferring billets between different areas of the production facility to ensure temperature consistency. Ensuring proper inventory management and tracking is also a challenge in billet handling. Steel billets are often stored in large warehouses or outdoor yards, and keeping track of their location, quantity, and quality can be complex. Efficient inventory management systems, such as barcoding or RFID tagging, are essential to minimize errors and efficiently retrieve the required billets for production. Lastly, safety is a significant concern when handling steel billets. The weight and potential for injury make it vital to follow strict safety protocols. Operators need to be properly trained on the use of equipment, such as cranes and forklifts, and wear appropriate personal protective equipment (PPE) to prevent accidents or injuries. Overall, the main challenges in the handling of steel billets during production revolve around their weight, potential for damage, temperature control, inventory management, and safety. Overcoming these challenges requires investments in specialized equipment, training, and efficient processes to ensure a smooth and successful production operation.

Send your message to us

Prime quality square alloy steel billet 120mm Q235

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords