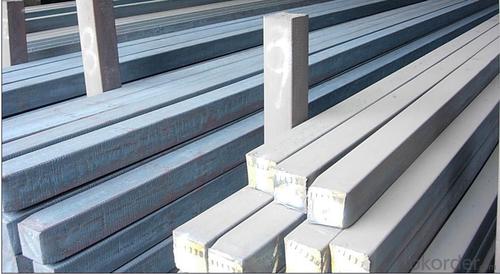

Prime quality square alloy steel billet 110mm Q235

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Structure of Prime quality square alloy steel billet 110mm Q235

Description of Prime quality square alloy steel billet 110mm Q235

1. Prepainted steel coil is coated with organic layer, which provides higher anti-corrosion property and a longer lifespan than that of galvanized or galvalume steel sheets.

2. The base metals for prepainted steel coil consist of cold rolled, HDGI Steel, electro-galvanized and hot-dip alu-zinc coated steel. The finish coats of prepainted steel coil can be classified into groups as follows: polyester, silicon modified polyesters, polyvinylidene fluoride, high-durability polyester, etc.

3. The production process has evolved from one-coating-and-one-baking to double-coating-and-double-baking, and even three-coating-and-three-baking.

4. The color of the prepainted steel coil has a very wide selection, like orange, cream-colored, dark sky blue, sea blue, bright red, brick red, ivory white, porcelain blue, etc.

5. The prepainted steel coils can also be classified into groups by their surface textures, namely regular prepainted sheets, embossed sheets and printed sheets.

Main Feature of Prime quality square alloy steel billet 110mm Q235

Uncoated CR steel sheet

With the features of in line with the international highest standards in demension and shape, excellent surface finish and properties, the products are mainly used in home appliance and automobile industries.

Galvanized steel sheet(include HDG and EG)

With the features of good corrosion resistance, the products are mainly used in automobile, home appliance, electronics, building and machinery manufacture industries, etc.

Precoated steel sheet

With the features of enviromental protection and good processablility, long lasting surface durability, rich in colors, the products are maily used in building, home appliance and furniture industries, etc.

Applications of Prime quality square alloy steel billet 110mm Q235

Construction

Manufacture anticorrosion, industrial and civil architecture roof boarding, roof grille

Light industries

Home appliance's case, civil chimney, kitchen utensils

Auto industry

Corrosion resistant parts of cars

Agriculture

Food storage, meat and aquatic products' freezing and processing equipment

Commerce

Equipments to store and transport materials, and packing implements

Specifications of Prime quality square alloy steel billet 110mm Q235

Product | Prime quality square alloy steel billet 110mm Q235 |

Material Grade | SGCC / SGCH / DX51D+AZ, etc |

Thickness | 0.6-3.0mm |

Width | 500-1500mm |

Tolerance | Thickness: +/-0.02mm , Width:+/-2mm |

Zinc-coating | Z30-150g/m2 |

Technique | Raw material: Hot rolled steel coil --> Cold rolled_>hot dipped galvalume |

Surface | Dried, Chromated, Unoiled |

Spangle | Regular spangle , small spangle, zero spangle |

ID | 508MM 610MM |

Coil weight | 1-25MT |

Export package | Cardboard inner sleeves, Waterproof paper, galvanized steel covered and steel strip packed |

FAQ of Prime quality square alloy steel billet 110mm Q235

We have organized several common questions for our clients,may help you sincerely:

1. How Can I Visit There?

Our company is located in Tianjin City, China, near Beijing. You can fly to Tianjin Airport Directly. All our clients, from home or aboard, are warmly welcome to visit us!

2. How Can I Get Some Sample?

We are honored to offer you sample.

3. Why choose CNBM?

Our delivery time about 15-20days for standard sizes, if you have other requirements like hardness, quanity and width ,it is about 20-40days. But don't worry we also try our best for the delivery time ,because time longer and our cost is higher.

- Q: What are the factors that affect the price of steel billets?

- The price of steel billets can be affected by several factors. 1. Raw material costs have a significant impact on the price of steel billets. Fluctuations in the cost of iron ore, coal, and other raw materials used in steel production directly influence the price of steel billets. 2. The supply and demand dynamics of steel billets play a crucial role in determining their price. An increase in demand for steel products, such as construction materials or automotive parts, can drive up the price of steel billets. Conversely, an oversupply can lead to a decrease in price. 3. Energy costs required for steel production can impact the price of steel billets. Fluctuations in energy prices affect the overall production cost and, subsequently, the price of steel billets. 4. Currency exchange rates can have a significant impact on the price of steel billets. If the currency of the country producing steel billets weakens against other currencies, it can make the product more affordable and potentially increase demand. 5. Government regulations, trade policies, and tariffs imposed on steel billets can influence their price. Tariffs can increase the cost of imported steel billets, making domestically produced steel billets relatively more competitive and potentially leading to higher prices. 6. The overall state of the economy, both locally and globally, can impact the price of steel billets. During periods of economic growth, there is typically higher demand for steel products, which can drive up the price. Conversely, during economic downturns, demand may decrease, resulting in lower prices. 7. Technological advancements in steel production can impact the price of steel billets. Innovations that increase efficiency and reduce production costs can potentially lead to lower prices, while new technologies that improve the quality or properties of steel billets may command a higher price. It is important to note that these factors are interconnected and can influence each other. Therefore, understanding the complex relationship between these factors is essential in analyzing and predicting the price of steel billets.

- Q: Can steel billets be coated for improved aesthetic appearance?

- Yes, steel billets can be coated to improve their aesthetic appearance. Coatings such as paints, powder coatings, and plating can be applied to steel billets to enhance their visual appeal. These coatings can provide a decorative finish, protect against corrosion, and improve the overall durability of the steel billets. Additionally, coatings can be customized to achieve specific aesthetic requirements, such as different colors, textures, or patterns, allowing for greater design flexibility. Therefore, coating steel billets is a common practice to achieve improved aesthetic appearance in various industries including construction, automotive, and consumer goods.

- Q: Can steel billets be cast from recycled steel?

- Yes, steel billets can be cast from recycled steel.

- Q: How do steel billets contribute to the overall durability of a product?

- Steel billets are an essential component in the manufacturing process of various products, and their contribution to the overall durability cannot be overstated. These billets are semi-finished steel products that are used as raw material for further processing in industries like construction, automotive, and manufacturing. One of the primary reasons why steel billets contribute to the overall durability of a product is their superior strength and toughness. Steel is known for its exceptional mechanical properties, including high tensile strength and resistance to deformation, making it an ideal choice for applications that require durability. By using steel billets as the starting material, manufacturers can ensure that the final product will possess the necessary strength to withstand heavy loads, impacts, and other external forces. Moreover, steel billets have excellent corrosion resistance. Steel, when properly processed and treated, can resist rust and other forms of corrosion caused by moisture, chemicals, or environmental factors. This corrosion resistance greatly enhances the durability of the final product, as it prevents degradation and extends the lifespan. Another advantage of using steel billets is their versatility in terms of customization. Manufacturers can shape and form the billets into various sizes and dimensions according to the specific requirements of the product. This flexibility allows for the production of components that perfectly fit together, reducing the risk of weak points or vulnerabilities in the overall structure. Additionally, steel's malleability and ductility enable it to be easily molded and welded, further enhancing the overall strength and durability of the final product. Furthermore, steel billets undergo rigorous quality control measures during the manufacturing process. These measures ensure that the billets meet strict industry standards and specifications, guaranteeing their reliability and consistency. The high-quality steel billets, in turn, contribute to the overall durability of the product by providing a strong and reliable foundation. In summary, steel billets play a pivotal role in enhancing the overall durability of a product. Their exceptional strength, corrosion resistance, versatility, and high-quality attributes make them an ideal choice for industries that prioritize durability. By utilizing steel billets as the raw material, manufacturers can create products that are capable of withstanding demanding conditions, ensuring longevity and customer satisfaction.

- Q: What are the main factors affecting the dimensional tolerances of steel billets?

- The main factors affecting the dimensional tolerances of steel billets include the quality of the raw material used, the manufacturing process employed, and the precision of the equipment and tools used during production. Additionally, environmental conditions such as temperature and humidity can also impact the dimensional tolerances of steel billets.

- Q: How are steel billets inspected for hardness?

- Steel billets are inspected for hardness using a variety of methods and techniques. One of the commonly used methods is the Rockwell hardness test. This test measures the depth of penetration of an indenter into the steel surface under a specific load. The hardness value is then determined based on the depth of penetration. The Rockwell hardness test provides a quick and reliable way to assess the hardness of steel billets. Another method used for hardness inspection is the Brinell hardness test. This test involves applying a specific load on a hardened steel ball and measuring the diameter of the indentation left on the steel surface. The hardness value is calculated based on the applied load and the diameter of the indentation. The Brinell hardness test is useful for large steel billets or when a larger area needs to be tested. Furthermore, Vickers hardness test can also be employed for inspecting the hardness of steel billets. This method utilizes a diamond pyramid-shaped indenter to create an impression on the steel surface. The diagonals of the impression are measured, and the hardness value is determined based on the applied load and the surface area of the impression. The Vickers hardness test is commonly used for materials with high hardness or small components. In addition to these traditional hardness testing methods, there are also advanced techniques available, such as ultrasonic testing and magnetic induction. Ultrasonic testing involves sending high-frequency sound waves through the steel billet and measuring the time it takes for the waves to be reflected back. Any variations in the hardness of the billet can be detected through changes in the ultrasonic waves. Magnetic induction, on the other hand, utilizes magnetic fields to assess the hardness of steel. By measuring the electrical conductivity and permeability of the steel billet, the hardness can be estimated. Overall, there are several techniques available for inspecting the hardness of steel billets, including Rockwell, Brinell, Vickers hardness tests, as well as ultrasonic testing and magnetic induction. These methods provide valuable information about the hardness properties of the billets, allowing manufacturers to ensure the quality and suitability of the steel for various applications.

- Q: How are steel billets used in the production of railway parts?

- Steel billets are an important raw material used in the production of railway parts. These billets are essentially semi-finished steel products that are cast into a specific shape and size, typically in a square or rectangular form. They serve as the starting point for the manufacturing process of various railway components. One of the primary applications of steel billets in the production of railway parts is for the manufacturing of rails. The billets are heated and then passed through a series of rolling mills to shape them into the desired rail profile. This process, known as rolling, involves applying pressure to the billet, which gradually elongates and shapes it into the rail section. The resulting rails are then cut to the required length and undergo further processes such as heat treatment and finishing to enhance their strength and durability. Apart from rails, steel billets are also used in the production of other crucial railway components such as wheels, axles, and various structural parts. For example, billets can be forged or machined to form the wheel blanks, which are subsequently processed to create the final wheel shape. Similarly, billets can be used to manufacture axles by forging and machining them into the desired dimensions and specifications. Additionally, steel billets may be employed in the fabrication of various structural parts used in railway infrastructure, including bridges, tunnels, and platforms. These billets are processed through different manufacturing techniques such as casting, forging, or machining to produce the required components. In summary, steel billets play a vital role in the production of railway parts. From manufacturing rails to wheels, axles, and structural components, these billets serve as the starting material that undergoes various shaping, heat treatment, and finishing processes to create the final railway components that ensure safe and efficient transportation.

- Q: What are the different types of steel billet forging machines?

- There are several different types of steel billet forging machines available in the market today. These machines are designed to efficiently shape and form steel billets into desired shapes and sizes. Here are some of the common types of steel billet forging machines: 1. Hydraulic Forging Press: This type of machine uses hydraulic power to exert force on the steel billet, allowing it to be forged into the desired shape. Hydraulic forging presses are known for their high force capabilities and versatility in handling different sizes of billets. 2. Mechanical Forging Press: Mechanical forging presses use mechanical power, such as flywheels or eccentric mechanisms, to exert force on the billet. These machines are known for their reliability and precision, making them suitable for high-volume production. 3. Screw Press: Screw presses utilize a rotating screw mechanism to apply force on the steel billet. They are characterized by their high-speed operation and efficient energy usage. Screw presses are commonly used for forging small to medium-sized billets. 4. Hammer Forging Machine: Hammer forging machines use a hammering action to shape the steel billet. There are various types of hammer forging machines, including steam hammers, air hammers, and hydraulic hammers. These machines are known for their high impact force, making them suitable for heavy-duty forging. 5. Upsetter: Upsetters, also known as upsetting machines, are specifically designed for forging the ends of steel billets. They use a vertical or horizontal ram to apply pressure on the billet, causing it to increase in diameter and length. Upsetters are commonly used for producing forged components with thickened ends. 6. Radial Forging Machine: Radial forging machines employ a rotating roller to apply radial force on the steel billet. This force causes the billet to increase in diameter while maintaining its original length. Radial forging machines are often used for producing seamless rings and other cylindrical components. It's important to note that the choice of the most suitable steel billet forging machine depends on factors such as the size and shape of the billet, desired production volume, and specific requirements of the final product. Each type of machine has its own advantages and limitations, so it is crucial to consider these factors when selecting the appropriate forging machine for a given application.

- Q: What is the role of steel billets in the manufacturing of automotive body panels?

- Steel billets play a crucial role in the manufacturing of automotive body panels as they are the starting material for the production process. These billets are heated, shaped, and formed into various body panel components, such as doors, hoods, and fenders. Their high strength and durability make them ideal for providing structural integrity and protection in automotive applications. Additionally, the malleability of steel billets allows for intricate designs and shaping, ensuring precise and smooth body panel surfaces.

- Q: What is billet?

- Steel billet is a product made by steel-making furnace by casting.The billet can be divided into two kinds from the manufacturing process, mould blank and continuous casting billet.

Send your message to us

Prime quality square alloy steel billet 110mm Q235

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords